Cryogenic vessel steel of minus 110 DEG C and manufacturing method thereof

A manufacturing method and technology of low temperature container, which are applied in manufacturing tools, heat treatment process control, heat treatment equipment and other directions, can solve the problems of high production process cost, complex production process and complex production process, achieve uniform and stable steel plate structure and reduce production cost , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments.

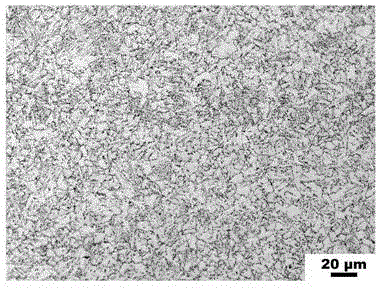

[0028] The chemical compositions of Examples 1 and 2 are shown in Table 1. The hot rolling and heat treatment process parameters adopted are: heating temperature 1150~1250 DEG C, heat preservation for 2 hours, starting rolling temperature 980~1150 DEG C, final rolling temperature 800~900 DEG C, cooling The speed is 10-15°C / s, the final cooling temperature is 450-600°C, the thickness of the finished steel plate after rolling is 30mm, the quenching temperature is 840-900°C, the holding time is 0.5-1.5h, the tempering temperature is 600-660°C, the holding time For 1 ~ 2h.

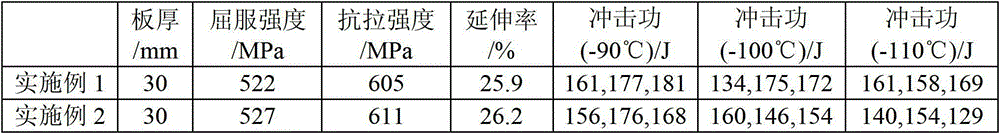

[0029] The mechanical properties of the steel plates of Examples 1 and 2 are shown in Table 2.

[0030] Table 1 The chemical composition (wt%) of the -110°C low-temperature container steel involved in Examples 1 and 2 of the present invention

[0031]

C

Si

mn

P

S ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com