Distiller with applicator for thin film evaporation and scraper for deposit removal

A technology of scraper and distiller, which is applied in the field of distillers and can solve the problems of huge energy demand and uncompetitiveness of distillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] A description of exemplary embodiments of the invention follows:

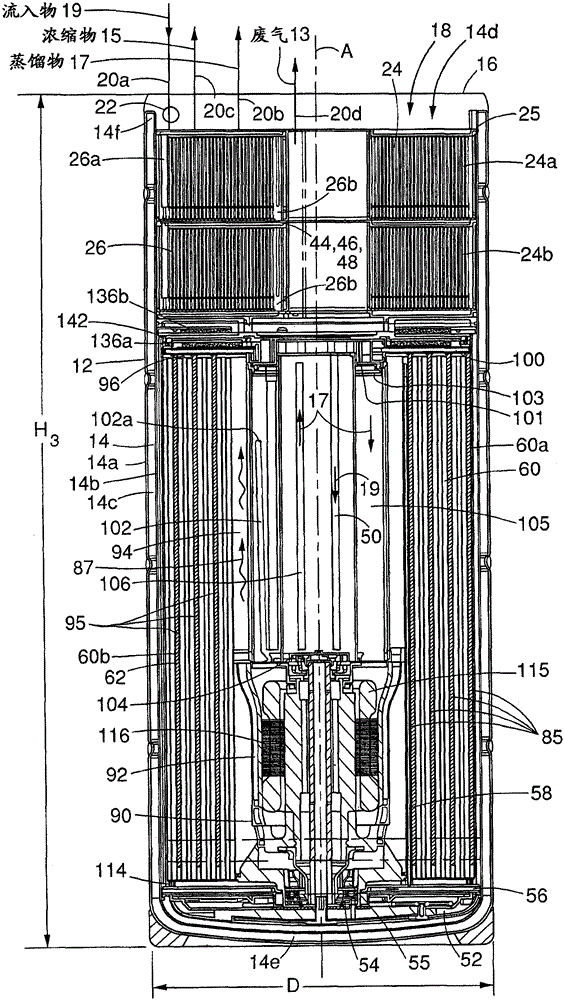

[0069] refer to figure 1 , in one embodiment, the still or distillation apparatus or apparatus 10 may be a vapor compression still and may distill a liquid or fluid such as water, alcohol, etc. to form the desired purified liquid. The water may be recycled water, polluted water which may be lakes, ponds, rivers, streams or ground water or waste water from residential premises or industrial buildings. Most commonly, the water is fresh water, but in some embodiments, may be brackish or salt water. The following description will describe the still in conjunction with distilled water as the influent or influent liquid, but it will be understood that the still 10 can distill other suitable liquids.

[0070] Distiller 10 may have a sealed housing 12 formed in part by an insulating Dewar 14 within housing 12 interior 18 , which surrounds and houses the internal components of distiller 10 . Dewar 14 may be gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com