Through-wall stirrer

A mixer and wall-type technology, which is applied in the field of equipment for stirring sludge in sludge fermentation tanks, can solve the problems of long length of the stirring shaft, large wear of the stirring shaft, poor stability, etc., and achieve good stability, small vibration, good straightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

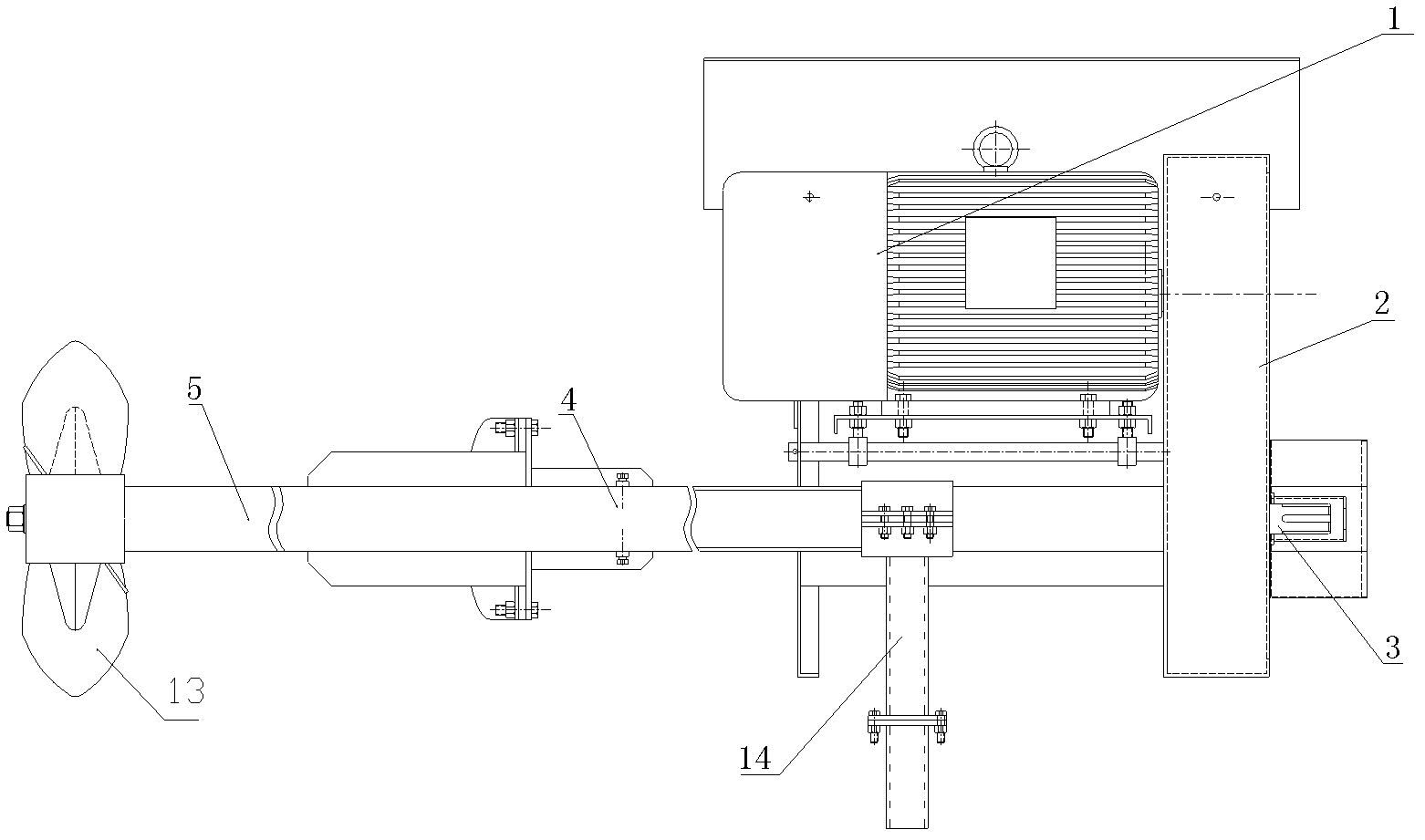

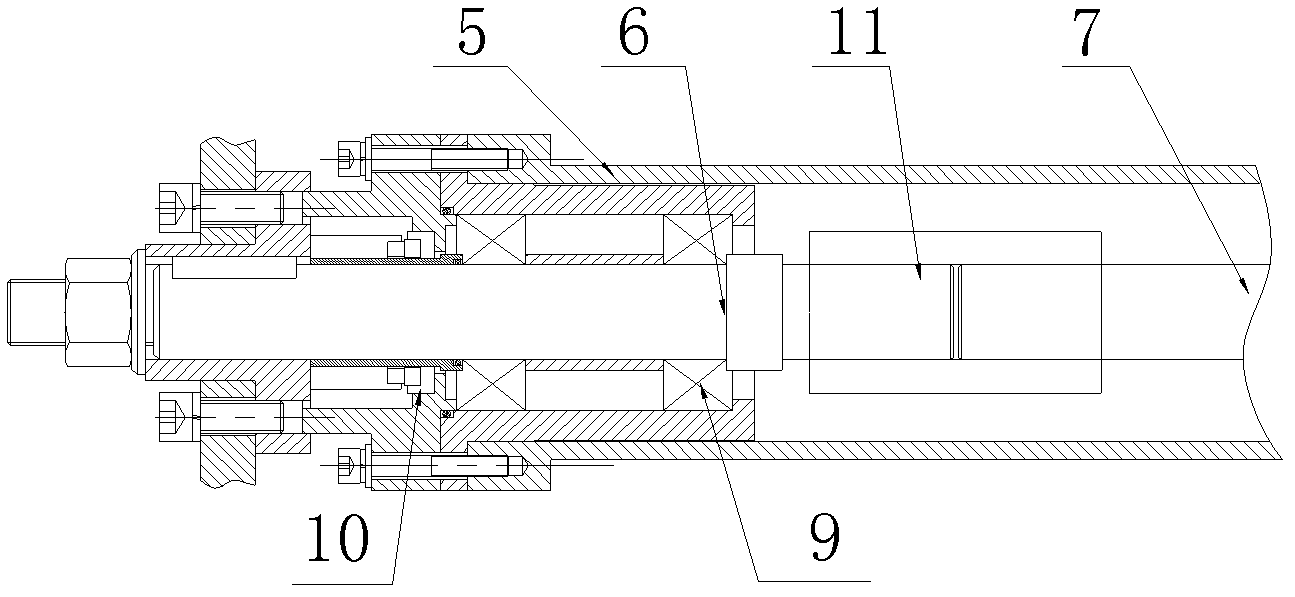

[0016] figure 1 It is an overall view of the mixer of the present invention, including a motor 1, a reducer 2, a rear shaft cover 3, a shaft tube 5, and an oil cup 4, a stirring paddle 13, and a bracket 14 are installed in the middle of the shaft tube 5.

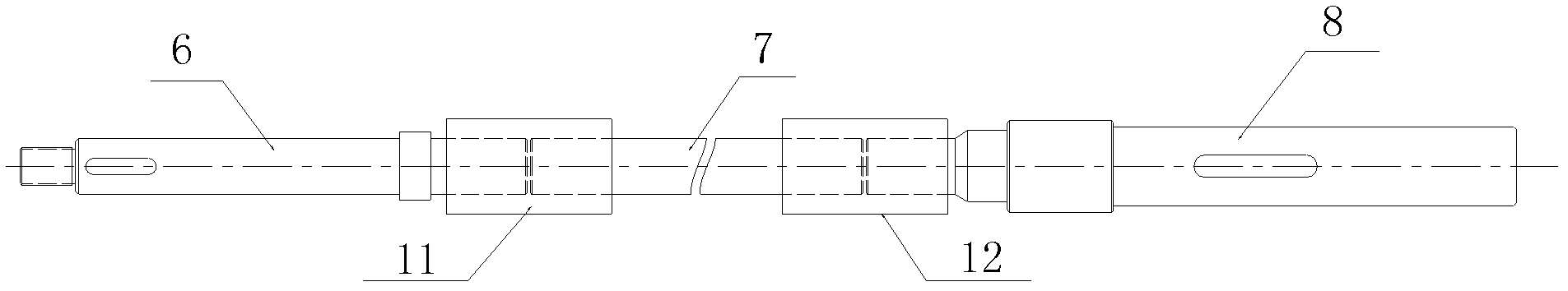

[0017] The through-wall mixer of the present invention includes a power part, a stirring part and a supporting part; the power part is a motor 1 and a reducer 2; the stirring part is a stirring paddle 13 and an integral stirring shaft; the supporting part is a bracket 14. The stirring shaft of the stirring part is sleeved in the shaft tube 5 of the supporting part, and the shaft tube 5 belongs to a part of the supporting part. The power part is connected with the stirring part, and the stirring part is installed on the support part; the support part supports the stirring part; the power part and the stirring part are connected through the reducer 2 or the belt pulley; the power part and the stirring part of the through-wall ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap