A kind of method that takes crude sulfate soap as raw material to prepare biodiesel

A sulfate soap and biodiesel technology, which is applied to the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, to achieve the effects of cost reduction, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Biodiesel was prepared from crude sulfate soap in a closed reaction system using concentrated sulfuric acid as a catalyst.

[0040] Dissolve 150 grams of crude sulfate soap (water content 33%, pH 9.5-10) in 400 ml of methanol, mix and place in a 1L round-bottomed flask, then add 30 mL of 96% concentrated sulfuric acid to the mixed solution, and place the round-bottomed The flask was capped tightly and the mixture was heated at 65°C for 1 hr.

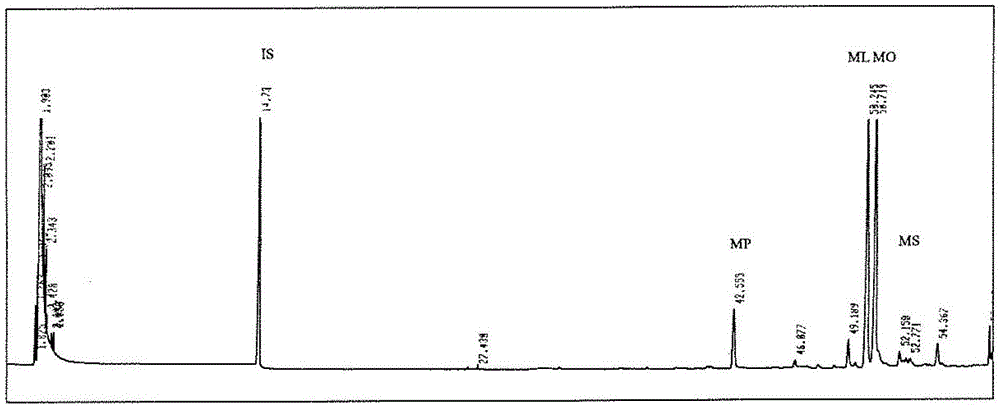

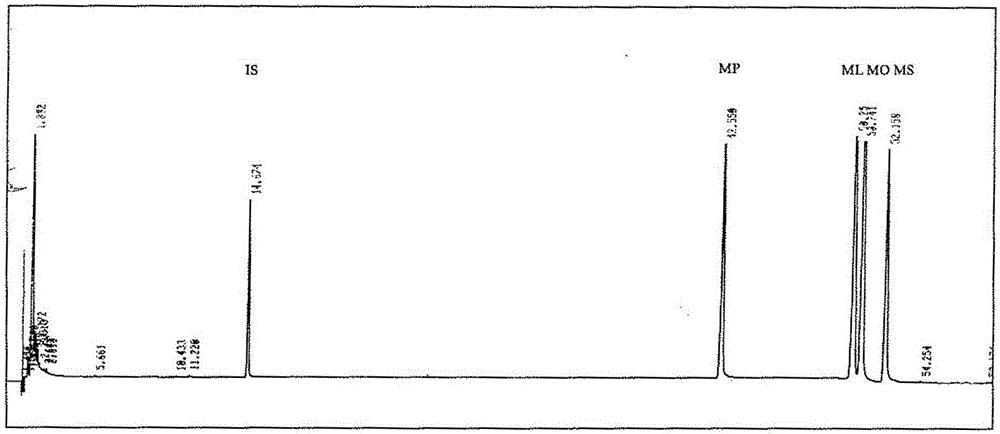

[0041] After the biodiesel reaction solution after the above reaction is distilled under reduced pressure to recover the solvent, the remaining substance is fully mixed with water to obtain a suspension. The volume ratio to the suspension is 1:2, let stand to separate, remove the water layer, the pH of the water phase is 1.0, it can be seen that the conversion reaction of biodiesel needs to be carried out under sufficiently strong acidic conditions; the organic layer can be reused Wash three times with water; combine t...

Embodiment 2

[0045] Example 2: Preparation of biodiesel from crude sulfate soap in a closed reaction system using concentrated sulfuric acid as a catalyst.

[0046] Dissolve 150 grams of crude sulfate soap (moisture content 33%, pH9.5-10) in 300 ml of methanol, mix and place in a 1L round-bottomed flask, then add 20 mL of 96% concentrated sulfuric acid to the mixed solution, and place the round-bottomed The flask was capped tightly and the mixture was heated at 60°C for 0.5 hr.

[0047] After the biodiesel reaction solution after the above reaction is distilled under reduced pressure to recover the solvent, the remaining substance is fully mixed with water to obtain a suspension. The volume ratio to the suspension is 1:2, let stand to separate, remove the water layer, the pH of the water phase is 2.0, it can be seen that the conversion reaction of biodiesel needs to be carried out under sufficiently strong acidic conditions; the organic layer can be reused Wash three times with water; com...

Embodiment 3

[0049] Example 3: Biodiesel was prepared from crude sulfate soap in a closed reaction system using concentrated sulfuric acid as a catalyst.

[0050] Dissolve 150 grams of crude sulfate soap (moisture content 33%, pH9.5-10) in 200 ml of ethanol, mix and place in a 1L round bottom flask, then add 10 mL of 98% concentrated sulfuric acid to the mixed solution, and place the round bottom The flask was capped tightly, and the mixed system was heated at 120°C for 15 minutes.

[0051] After the biodiesel reaction solution after the above reaction is recovered by distillation under reduced pressure, the remaining substance is fully mixed with water to obtain a suspension. The volume ratio to the suspension is 1:1, let stand to separate layers, remove the water layer, the pH of the water phase is 1.5, and wash the organic layer three times with water; combine the organic layers, and evaporate the ethyl acetate in it under reduced pressure ; Then distill under reduced pressure (2mmHg) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com