Special integral impeller five-axis side milling clamp capable of measuring milling force

A special fixture and integral impeller technology, which is applied in the direction of clamping, manufacturing tools, measuring/indicating equipment, etc., can solve the problems that the concentric positioning of the fixture and the impeller blank cannot be guaranteed, the impeller clamping and positioning takes a long time, and the milling force cannot be measured in real time. , to achieve the effect of real-time measurement of milling force, saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

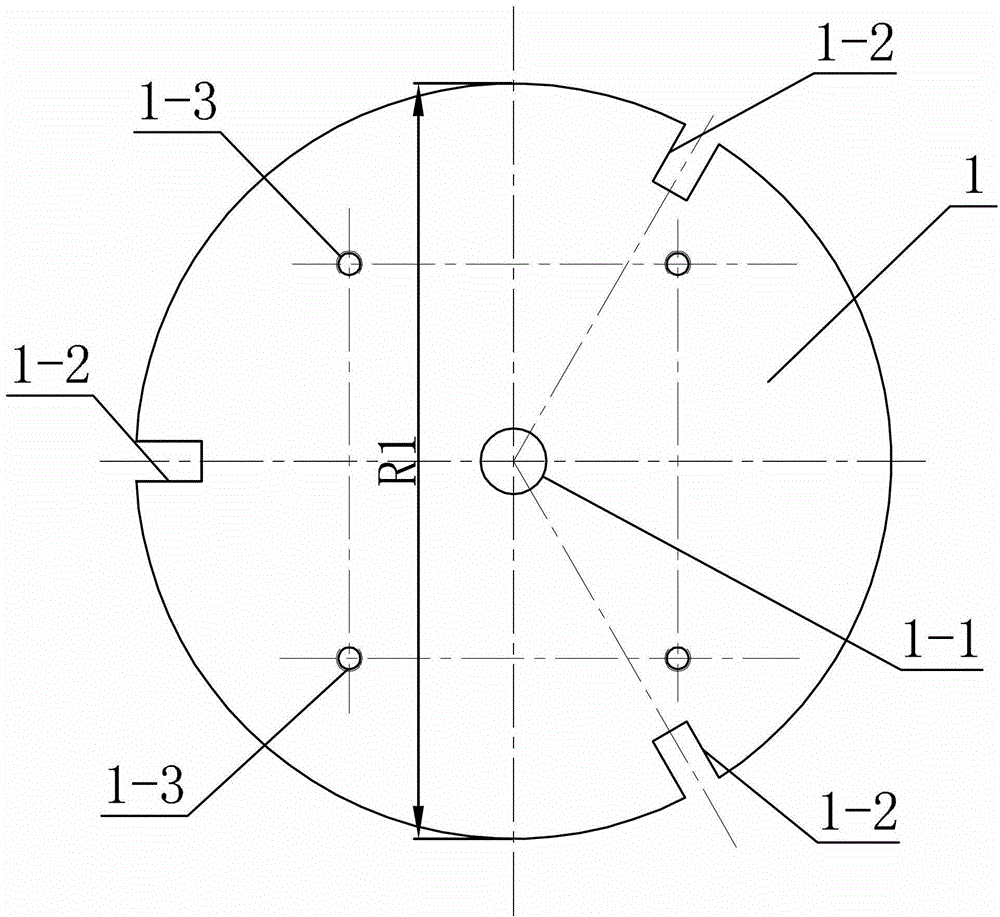

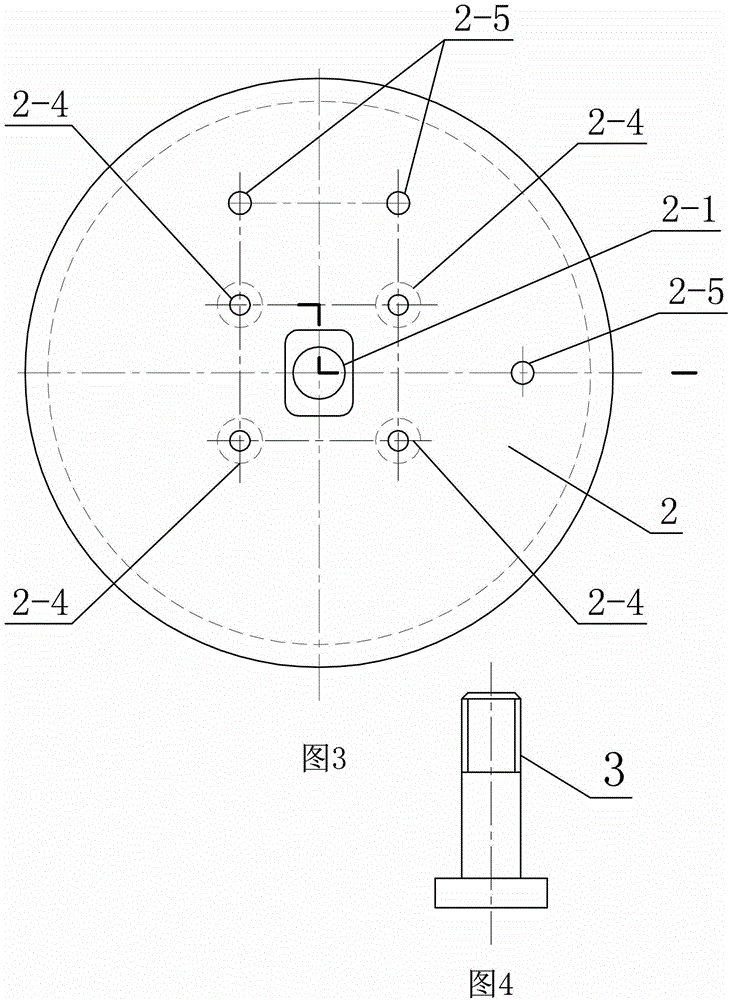

[0016] Specific implementation mode one: as Figure 1~6 As shown, the special fixture for five-axis side milling of integral impeller with measurable milling force in this embodiment includes a first positioning disc 1, a second positioning disc 2 and a fixed mandrel 3, and the first positioning disc 1 is machined with a center Hole 1-1, the edge of the first positioning disc 1 is uniformly processed with three rectangular grooves 1-2 along the circumferential direction, and four positioning thread through holes 1-3 are processed on the first positioning disc 1, four positioning threads The through holes 1-3 are arranged in a rectangular shape, the first positioning disc 1 is fixed on the upper end surface of the turntable of the five-axis milling machine, and the dynamometer is fixed on the upper end surface of the first positioning disc 1 through screws;

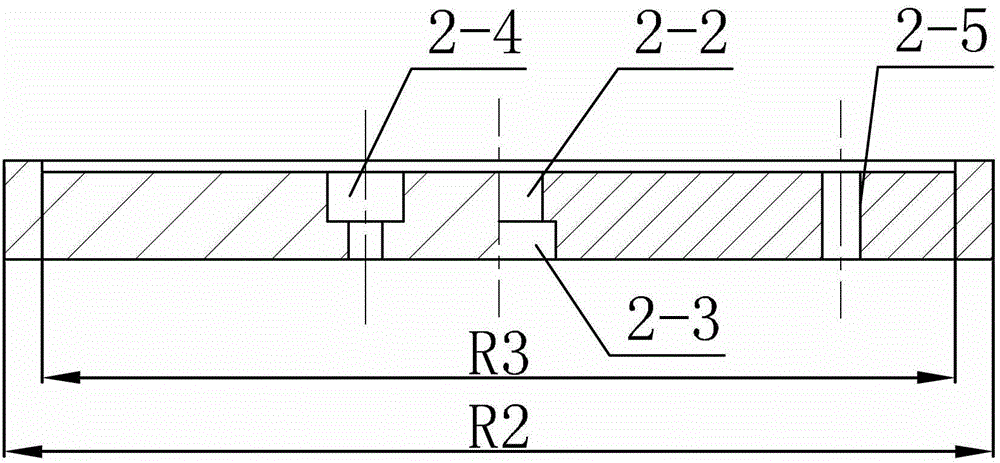

[0017] The center of the second positioning disc 2 is processed with a shoulder hole 2-1, and the shoulder hole 2-1 is c...

specific Embodiment approach 2

[0027] Specific implementation mode two: as figure 1 As shown, the diameter R1 of the first positioning disc 1 in this embodiment is 230 mm. Such a design facilitates the center positioning of the turntable of the machine tool and the connection between the two through three evenly distributed rectangular slots. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: as figure 2 As shown, the diameter R2 of the second positioning disc 2 in this embodiment is 260 mm. Such a design can not only satisfy the rapid positioning of the second positioning disc 2 on the dynamometer, but also ensure reliable and stable support of the upper impeller blank. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com