Rotary electric machine rotor

A technology of rotary electric machine and rotor, applied in the field of rotor, can solve the problem of high magnetic permeability of electromagnetic steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Selected embodiments will now be explained with reference to the drawings. It will be apparent to those skilled in the art from this disclosure that the following description of the embodiments is provided for illustration only and not for the purpose of limiting the invention as defined by the appended claims and their equivalents.

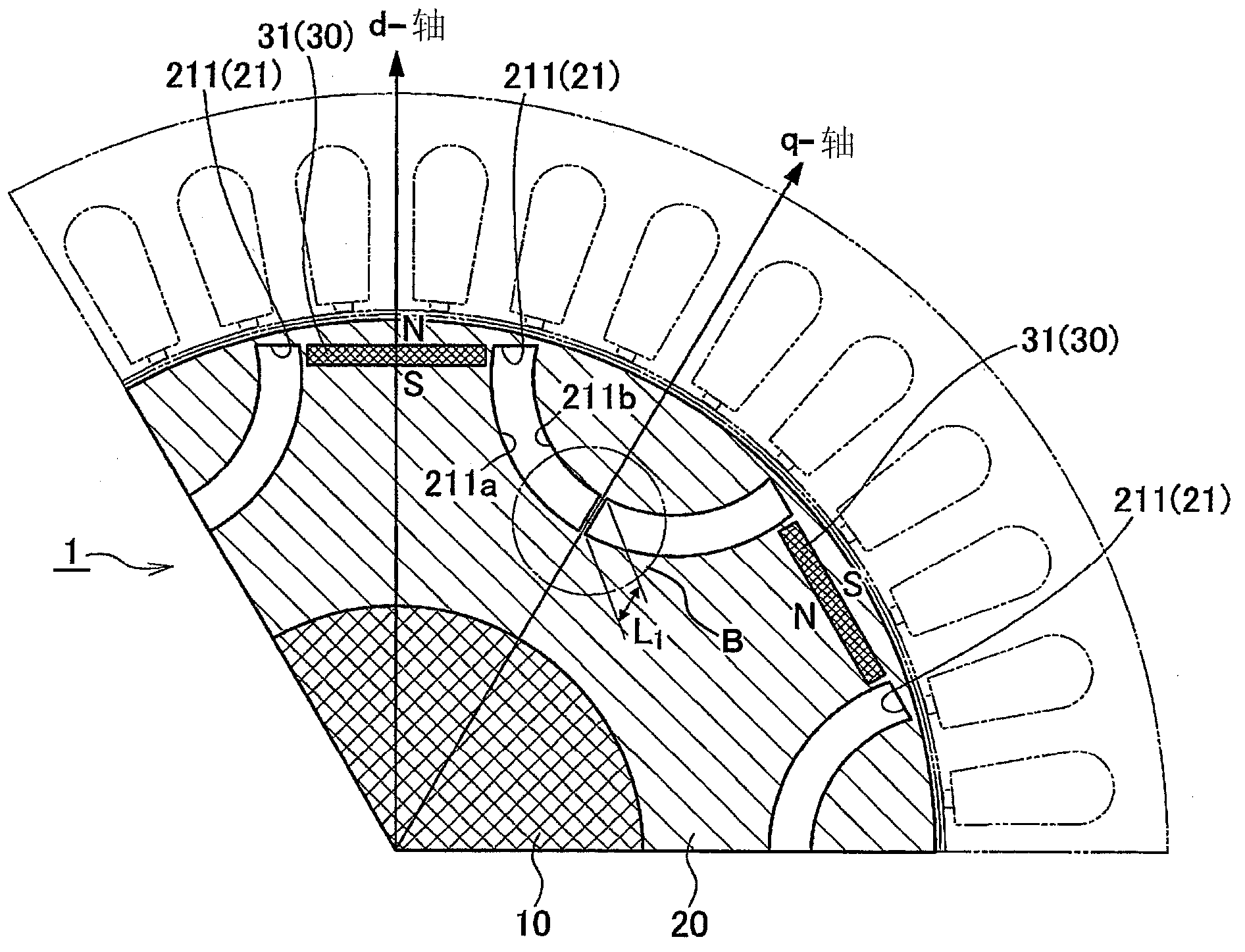

[0025] First refer to Figure 1A , illustrating a partial transverse cross-sectional view of a part of the rotor of a rotary electric machine according to the first embodiment, in a section taken along a section line lying in a plane perpendicular to the axis of the rotor shaft, and Figure 1A 1 / 3 (120 degrees) of the full circumference of the rotor is shown.

[0026] Figure 1B yes Figure 1A A magnified view of part B of , and figure 2 is included Figure 1A A full cross-sectional view of this part is shown in . The rotary electric machine rotor 1 in this example has a rotor shaft 10 , a rotor core 20 and a set 30 of permanent magnets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com