Fixing device for clamping mold and construction method of clamping mold

A fixing device and mold clamping technology, applied in the direction of mold shell/template/work frame, connection parts of mold shell/template/work frame, and on-site preparation of building components, which can solve the problem of uneven material at the boundary of the spraying area , without the problems of load-bearing and low strength, to achieve the effect of fast construction speed, leveling strength, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

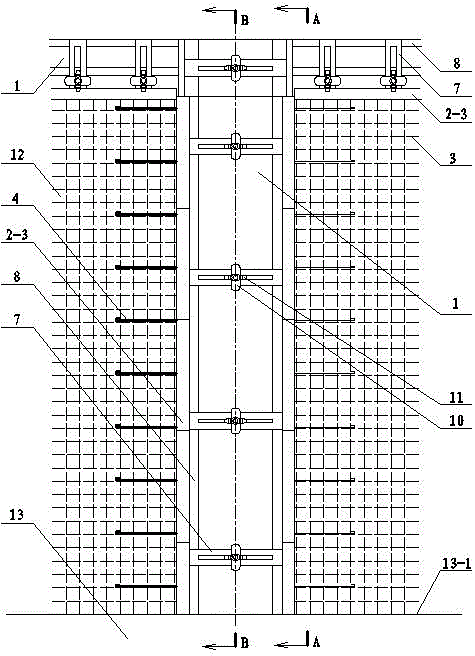

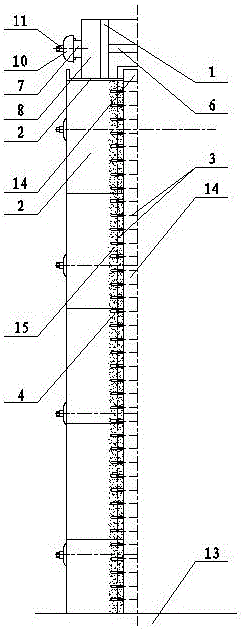

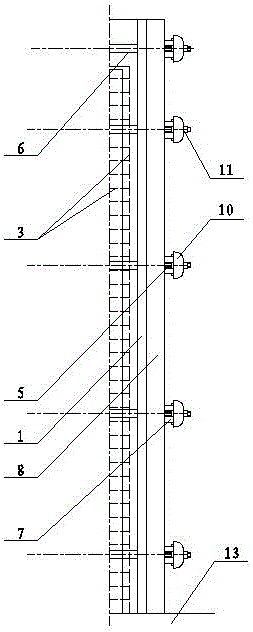

[0028] see Figure 1-5, the present invention provides a clamping mold fixing device, comprising a pair of main formwork 1 and one or more side formworks 2, the main formwork is a rectangular plate, and the side formwork is at least one straight side 2-1 Plates, in the assembled state, the faces of the paired main formworks are arranged in parallel and at intervals, at least one long side edge of at least one main formwork is fixedly connected to the side formwork, and the plate surface of the side formwork is perpendicular to the plate surface of the corresponding main formwork And be attached to the end face of the corresponding long side of the corresponding main template, the straight side extends between the pair of main templates and is parallel to the surface of the main template, when there are multiple side templates set on the long side , the plurality of side templates are continuously and closely connected; the side templates can be a whole board without holes or g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com