Continuous flapping-wing aircraft

A flapping-wing aircraft and wing-rotating technology, applied in the field of continuous flapping-wing aircraft, can solve the problems of difficult manufacturing design, high cost, complex structure, etc., and achieve the effect of easy and accurate control of reverse thrust direction and high mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

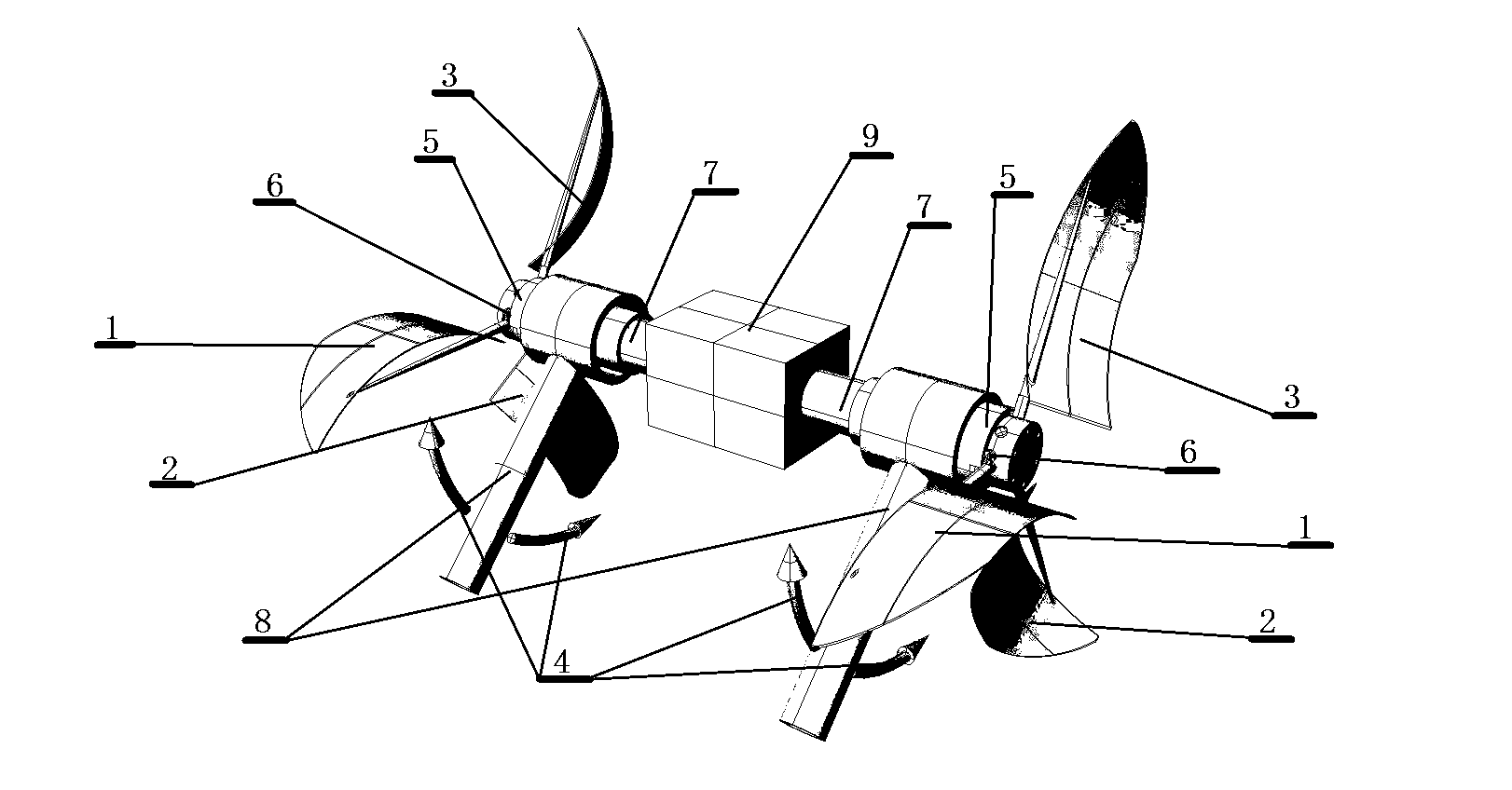

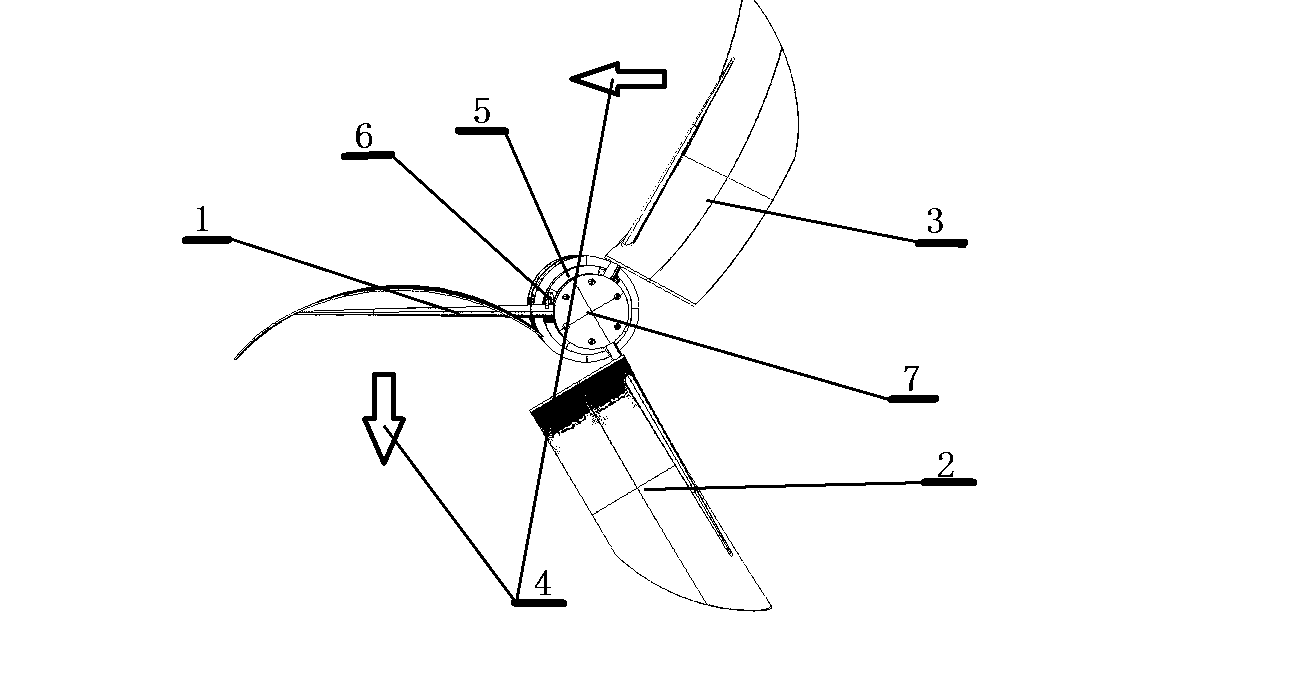

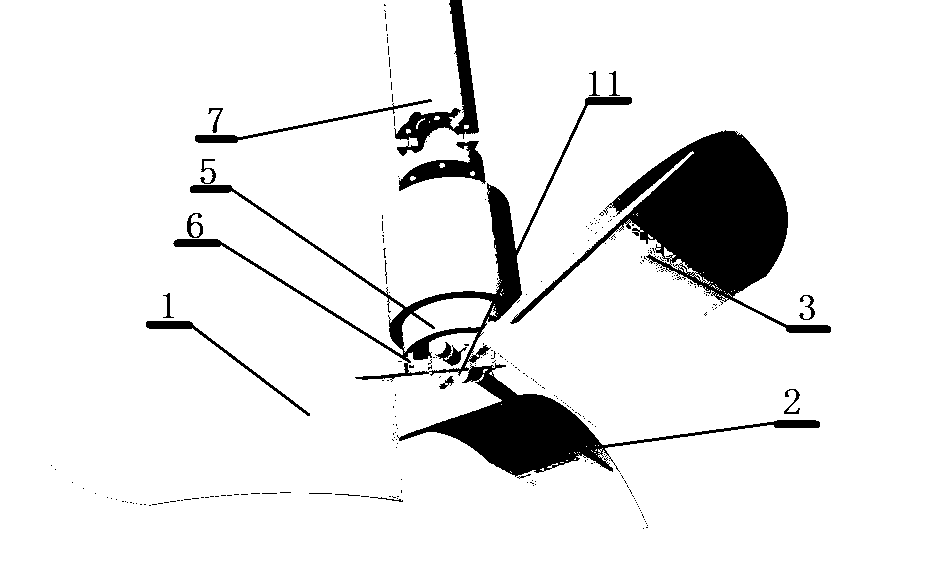

[0009] The structure of the continuous flapping wing aircraft of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] A continuous flapping wing aircraft, characterized in that it is composed of two continuous flapping wing devices connected with an engine 9. The continuous flapping wing device includes a main shaft 7, a control assembly 5, and a first flapping wing 1, a second flapping wing 2, and a second flapping wing. The three-pointed star-shaped through-coaxial device 11 is formed by connecting the rotating wing shafts of the three flapping wings 3; two continuous flapping wings are installed on both sides of the engine 9, and the main shafts 7 of the two continuous flapping wings are respectively installed on the engine 9 The main shaft; the control assembly 5 is composed of the convex portion 12, the concave portion 13, and the control rod 8 are connected into one body. The control assembly 5 is sleeved on the main s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap