Planar electromagnetic sensor based sheet damage detection apparatus and method thereof

An electromagnetic sensor and detection device technology, applied in the direction of material magnetic variables, etc., can solve the problems of single sampling data, weak acquisition signal, misjudgment of detection results, etc., and achieve the effect of accurate detection data, high sensitivity and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

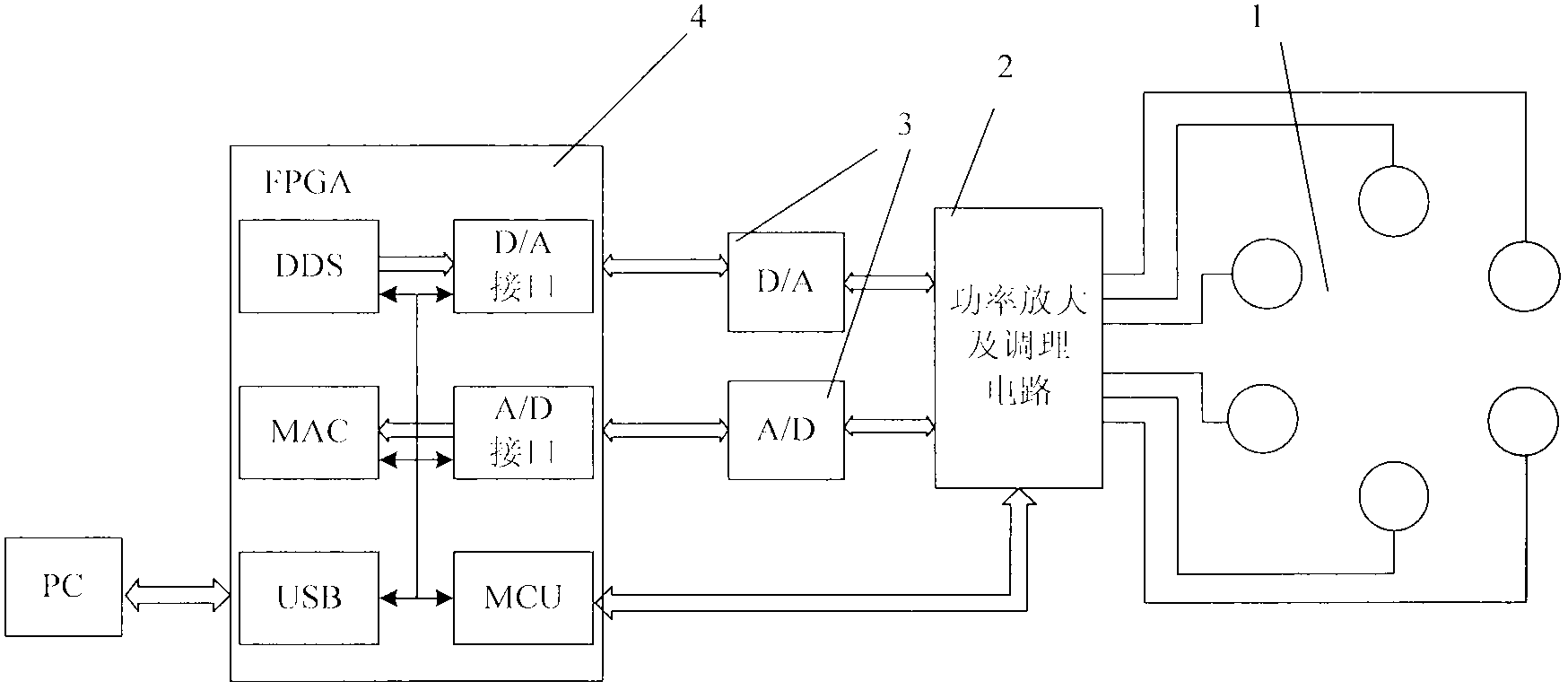

[0019] The electromagnetic flaw detection imaging sensor system proposed by the present invention is used in the field of metal component or plate damage detection, and can effectively discriminate the electromagnetic parameter information and state of the metal component under test. At the same time, the increase in the amount of parameter acquisition can provide more imaging for the detection system , complete test information. The structure of flaw detection imaging system (such as figure 1 (shown) mainly includes: a new type of electromagnetic flaw detection imaging sensor 1, a signal conditioning circuit 2, an A / D conversion circuit 3, a D / A conversion circuit 4, an FPGA chip 5 as a control center, and six parts of a host computer.

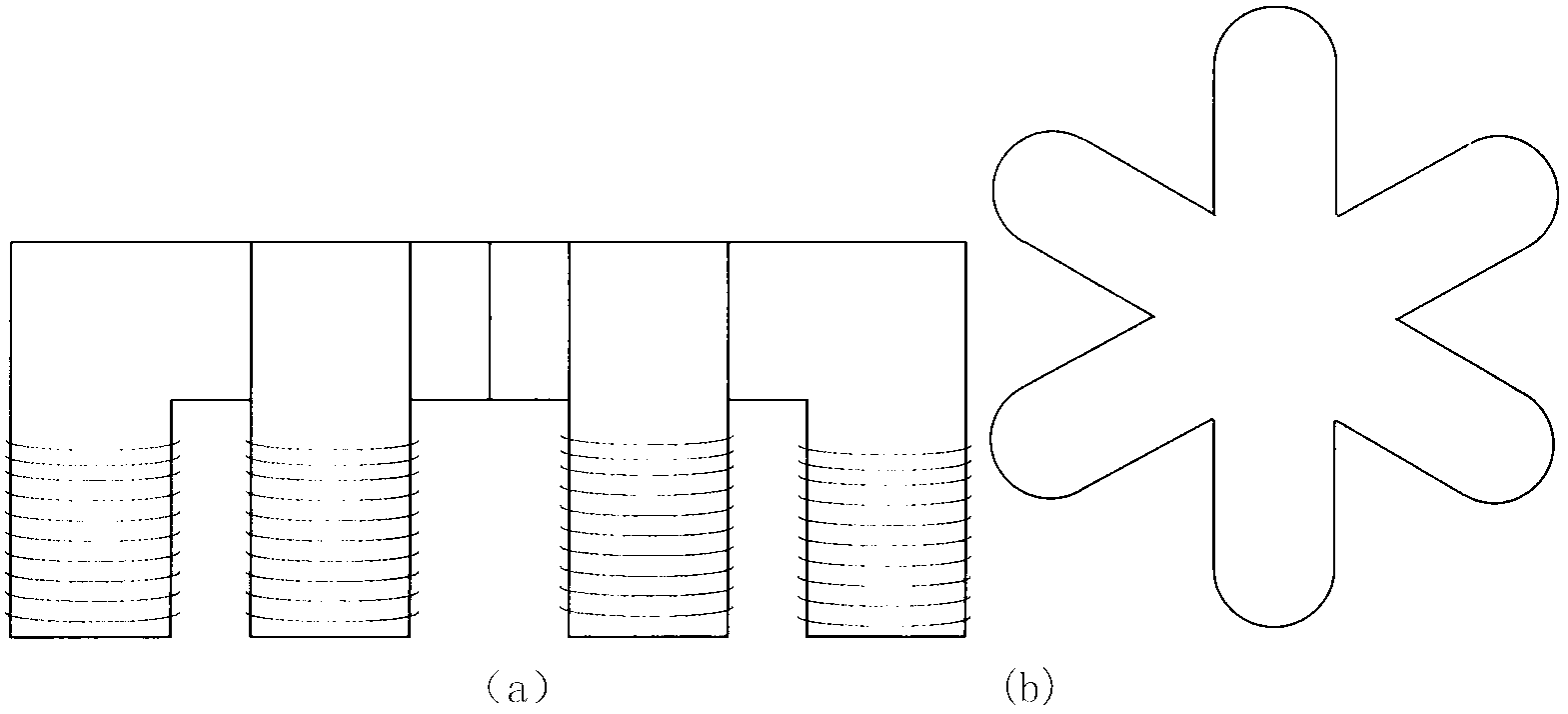

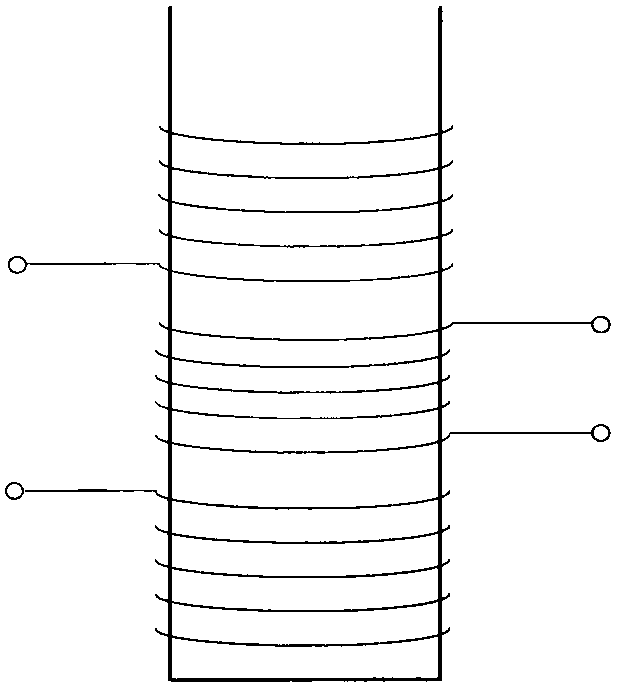

[0020] The electromagnetic flaw detection imaging sensor (1) is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com