Spherical filling body for reinforced concrete hollow component and fixation method

A technology of reinforced concrete and hollow components, which is applied to building components, on-site preparation of building components, and building construction. It can solve problems such as low construction efficiency and quality, and difficult positioning of hollow structural components, and achieve convenient construction. The effect of preventing trampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as Figure 1~4 shown.

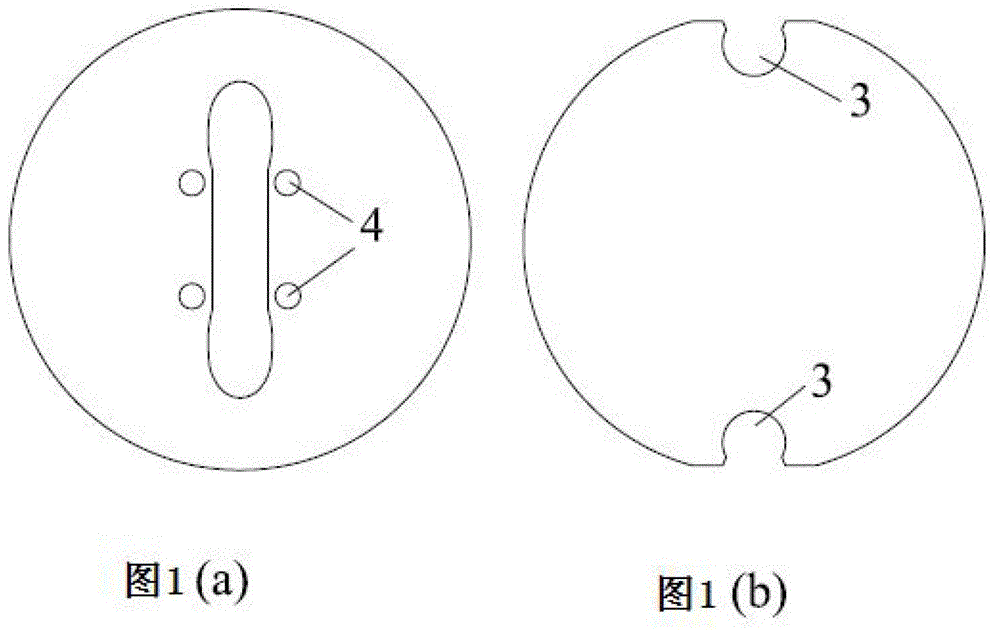

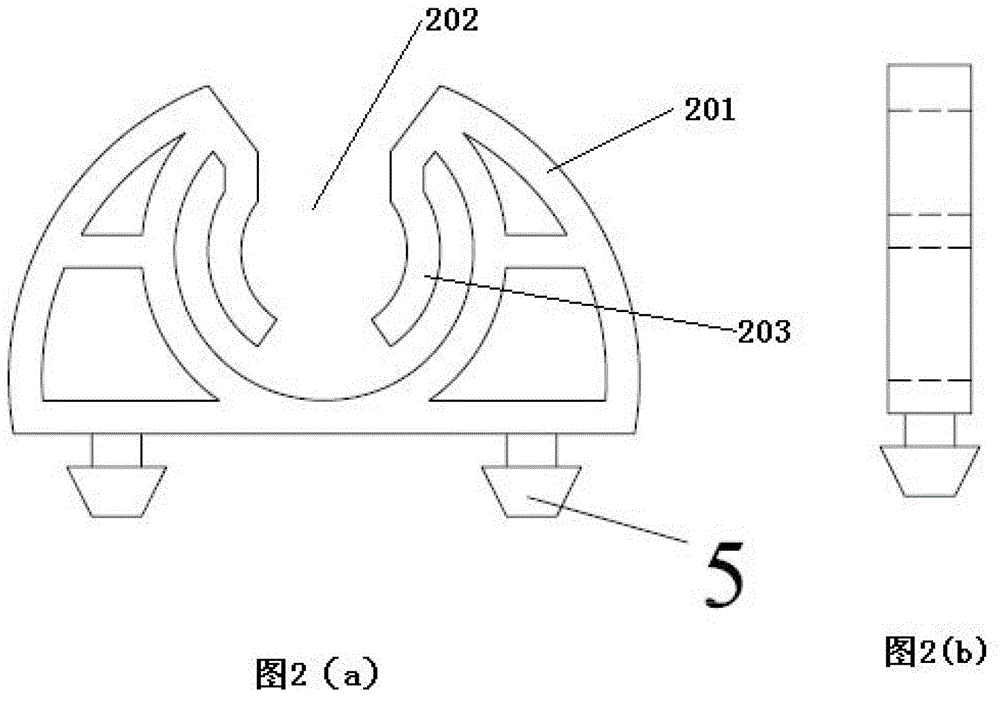

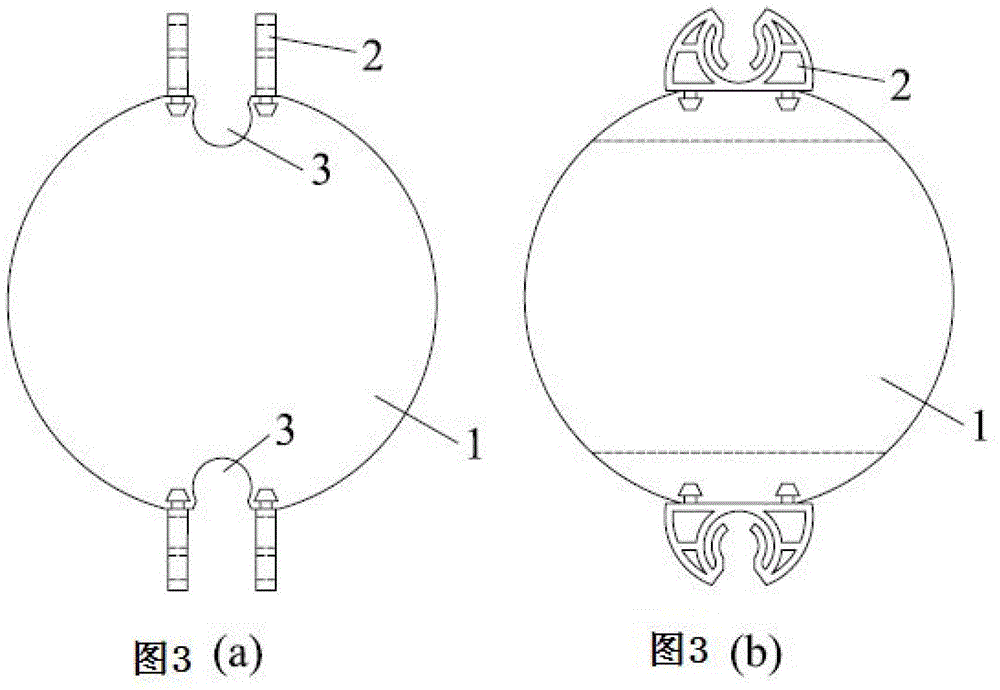

[0042] A spherical filling body for a reinforced concrete hollow member, which is composed of a hollow ball 1 for producing a hollow structure in the reinforced concrete and a fixing clip 2 for clamping and connecting with the steel bars in the reinforced concrete so as to position the hollow ball, Such as image 3 shown. The hollow ball 1 is a spherical thin-walled hollow body made of hard plastic with certain strength and bearing capacity. The top and bottom of the hollow ball 1 are provided with two grooves 3, and the two grooves 3 can Parallel arrangement can also be arranged according to the specific direction of the steel mesh, wherein the parallel arrangement is the best, and one side or both sides of the groove 3 are provided with holes 4 for the insertion of the inverted cone 5 protruding from the bottom of the fixed card 2, such as figure 1 (a), in order to increase the fixation strength, figure 1 A structure in which holes are...

Embodiment 2

[0046] A method for fixing spherical fillers for reinforced concrete hollow members, comprising the following steps:

[0047] First, press the hollow ball of the present invention with the steel bar in one direction of the bottom layer, so that the steel bar is stuck into the groove at the bottom of the hollow ball, so that a row of hollow balls is "stringed" on the steel bar. In this process, pay attention to the spacing of the steel bar grid Control the position of the hollow ball;

[0048] Secondly, install the bottom fixing card so that the fixing card and the bottom of the hollow ball are integrated as a whole, fine-tune the position of the hollow ball, and embed the steel bar in the other direction (perpendicular to the direction of the groove) of the bottom floor into the fixing card, thus forming an orthogonal two-way at the bottom of the floor. The reinforcement grid, and the spherical filling body is fixed to the reinforcement node;

[0049] The third step is to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com