Fuel distributor for gasoline and natural gas

A fuel distributor and fuel distribution technology, which is applied in low-pressure fuel injection, low-pressure fuel injection, fuel injection devices, etc., can solve the problems of increased assembly time and increased number of parts, and achieve reduced installation space, improved layout, and shortened assembly the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

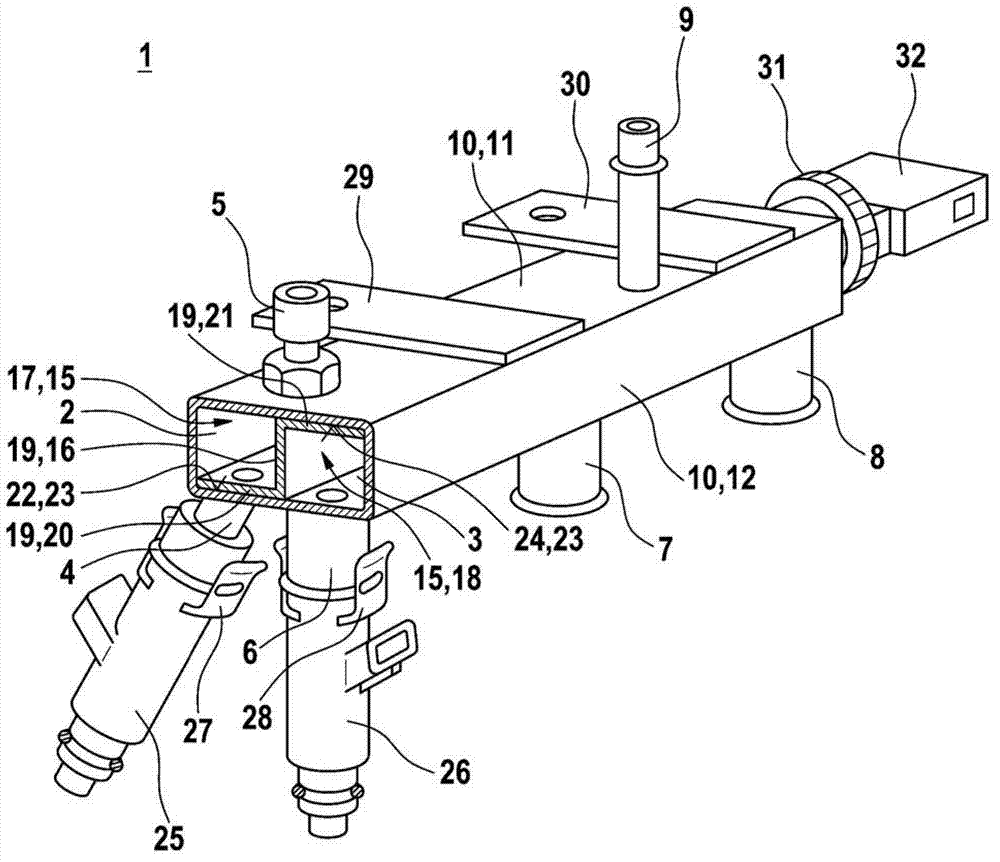

[0014] figure 1 The fuel injector 1 corresponding to the embodiment of the present invention is shown in a simplified schematic perspective view. The fuel distributor 1 can be used especially as a combined fuel distribution pipe of a fuel injection system of a compressed external ignition internal combustion engine. The fuel distributor 1 has a first fuel distribution device 2 and a second fuel distribution device 3. Here, the first fuel distribution device 2 is used to distribute natural gas to a plurality of connection points 4, which are figure 1 Shown in connection point 4. The first fuel distribution device 2 also has a connection point 5 configured as an inlet for natural gas. Here, compressed natural gas is preferably used as natural gas. The second fuel distribution device 3 is used to distribute gasoline to a plurality of connection points 6, 7 and 8 of the second fuel distribution device. Furthermore, the second fuel distribution device 3 has a connection point 9...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap