Reciprocating feeding device of circulating fluidized bed boiler burning biomass

A technology of circulating fluidized bed and feeding device, which is applied in the direction of fluidized bed combustion equipment, fuel burned in molten state, combustion method, etc., and can solve problems such as feeding blockage and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

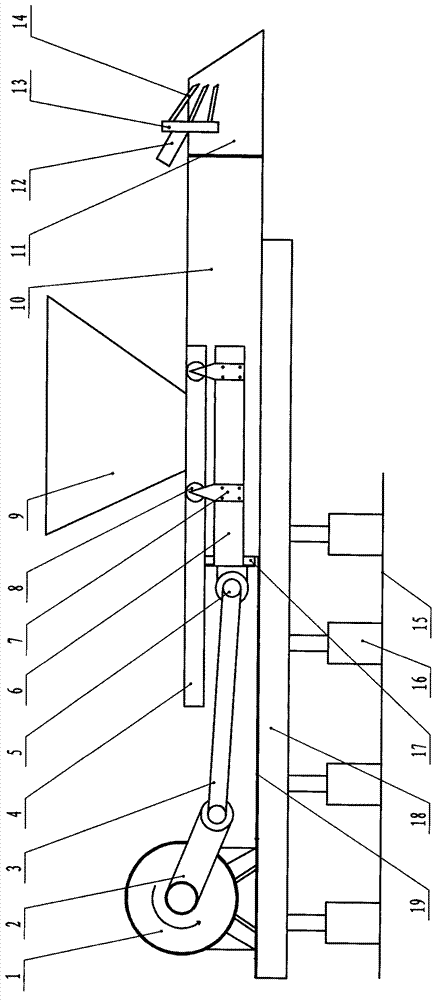

[0012] Refer to attached figure 1 , the present invention includes: a reducer 1, a hopper 9, a barrel 10 and a feeding piston 17, the hopper 9 is located above the barrel 10, the slideway 4 is located inside the barrel 10, the rocker arm 2 is located on the reducer 1; the reducer 1 The feeding piston 17 is connected with the connecting rod 3 and the connecting ring 5. The feeding piston 17 is composed of a sliding connecting rod 6, a pulley bracket 7 and a pulley 8. The pulley 8 is connected with the pulley bracket 7. The feeding piston 17 can move along the slideway. 4 reciprocating movement; the front part of the barrel 10 has a barrel casting 11 and a sealed main pipe 12, and the sealed main pipe 12 is composed of a sealed header 13 and a sealed branch pipe 14; The bracket 18 and the reducer base plate 19, the reducer 1 and the barrel 10 are located above the reducer base plate 19.

[0013] Working principle of the present invention: when the speed reducer 1 rotates counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com