Segmented Jacketed Water Tank

A segmented and jacketed technology, which is applied in solar thermal power generation, fluid heaters, heating devices, etc., can solve the problems of ceramic explosion, aggravated stress concentration at the welding point between the jacket and the outer surface of the inner tank, and powder drop. Achieve the effect of avoiding powder falling or porcelain bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

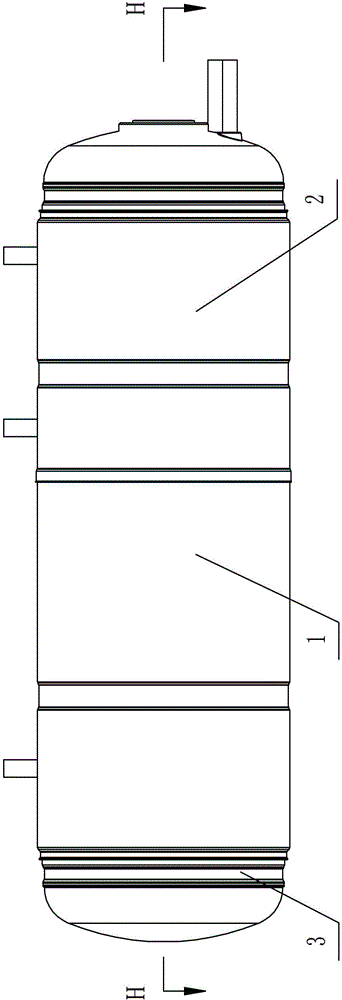

[0021] Specific implementation methods: such as figure 1 and figure 2 As shown, this embodiment includes an inner container 3 and a jacket welded to the outer surface of the inner container 3, the jacket is composed of a first sleeve 1 and a second sleeve 2, and the inner surface of the inner container 3 is provided with an enamel layer (not shown in the figure) Show). The left and right ends of the liner 3 are provided with an annular protrusion 31 as a welding pressure type, such as image 3 and Figure 5 Shown; The left end of the first sleeve 1 is provided with a connecting flange 11 as a welding pressure type, as image 3 Shown; The second sleeve 2 right-hand side is provided with the connection flanging 21 as welding pressure type, as Figure 5 As shown, and the left end of the second sleeve 2 is provided with flanging 23, such as Figure 4 shown.

[0022] First, the connecting flange 11 at the left end of the first sleeve 1 is welded close to the annular protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com