Annular suspension protection liquid of annular suspension mechanical seat seal oil well and construction process thereof

An annulus protection fluid and annulus machinery technology, applied in wellbore/well components, earthwork drilling and production, etc., can solve the problems of carbon steel tubing and casing corrosion control, the upward force of the wellhead, and the ease of thawing at the wellhead, etc. problems, to achieve the effect of low cost, convenient pressure relief and high compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example 1

[0031] Add 10% of emulsifier oxyethylene sorbitol monooleate span-80 (Jiangsu Province Haian Petrochemical Plant) in order by mass percentage in a liquid mixing tank with a capacity of 10L, 0.5% of salt and salt resistance High-temperature foaming agent polyoxyethylene alkyl alcohol ether (Hai'an Petrochemical Plant, Jiangsu Province), 0.3% foam stabilizer plant colloid KD-03 (Jiangsu Runda), 0.1% layering regulator polyoxypropylene Polyoxyethylene ether (Haian Petrochemical Plant in Jiangsu Province), 28% white oil, 0.5% corrosion inhibitor alkynyloxymethyl quaternary ammonium salt (Shanxi Yixintai), the rest is water, 3000rpm continuous stirring and dosing; A nitrogen gas of 8-10% by volume is introduced, and stirring is continued at 3000 rpm for 30 minutes to form a homogeneous foam emulsion. Put the foam emulsion at room temperature 25℃, pass the stability test, the result shows that its stability time> 72hr.

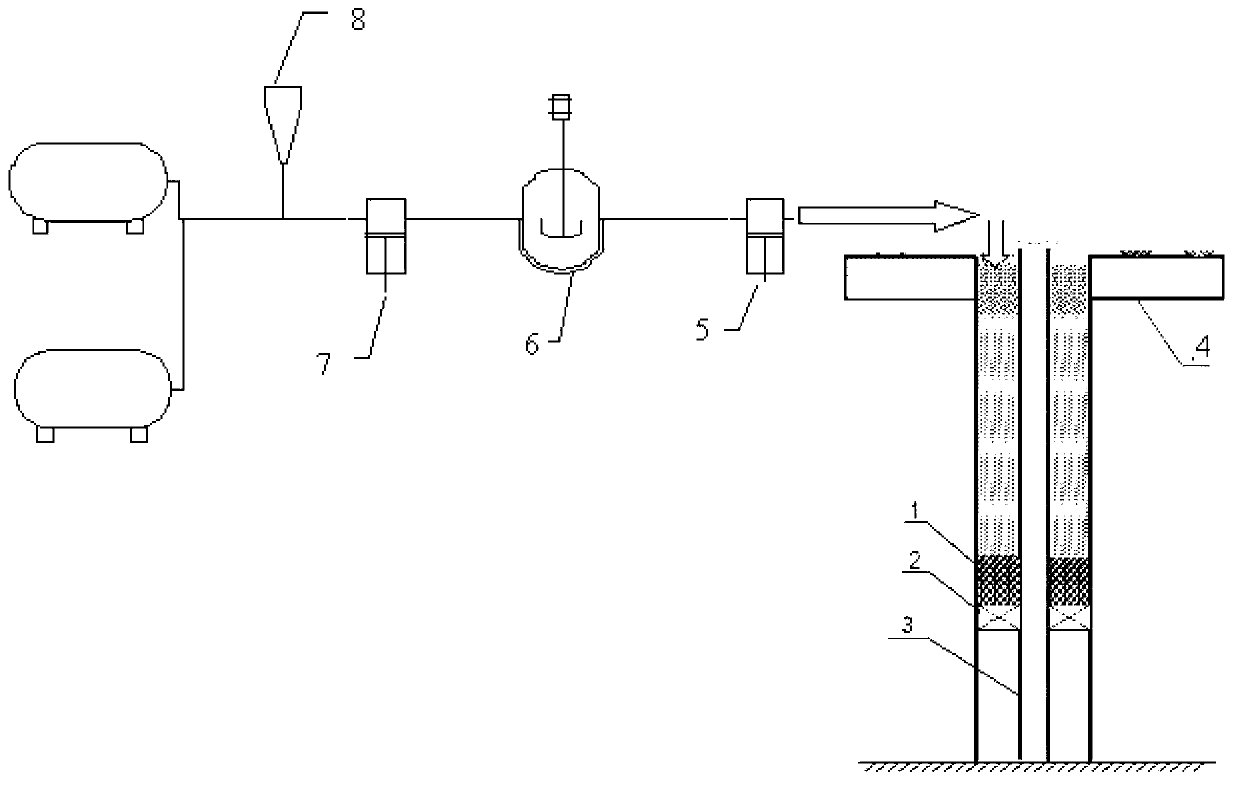

[0032] See figure 1 , Use the dosing pump truc...

Example Embodiment

[0033] Example 2

[0034] In terms of mass percentage, liquid formulation according to the components: 0.1% non-ionic surfactant foaming agent alkylphenol polyoxyethylene ether (Haian Petrochemical Plant in Jiangsu Province), 0.1% foam stabilizer polyacrylamide HPAM ( Henan Yiqing), 14% of the emulsifier oxyethylene sorbitol tristearate span65 (Jiangsu Haian Petrochemical Plant), 0.2% of the regulator phenolamine resin ether (Jiangsu Haian Petrochemical Plant), 25% White oil, 0.1% imidazoline corrosion inhibitor SK-05 (Sayangke Ruoxing Chemical), and the rest is water.

[0035] See figure 1 , Use the dosing pump truck 7 to prepare the liquid from the dosing port 8 in the dosing tank 6 according to the formula, and continue to stir the dosing to form a foamy emulsion with uniform phase (no stratification). Clean the annulus between the tubing 3 and the casing 1, and then seal the packer 2. After completion, use the liquid injection pump truck 5 to inject the annulus protection liq...

Example Embodiment

[0036] Example 3

[0037] Calculated by mass percentage, formulating liquid according to component formula: 12% polyoxyethylene sorbitol trioleate Span85 (Jiangsu Province Haian Petrochemical Plant), 0.5% foaming agent polyoxyethylene alkyl alcohol ether (Jiangsu Province Haian Petrochemical plant), 0.2% carboxymethyl cellulose sodium salt CMC foam stabilizer (Jiangsu Runda), 0.2% layering regulator hydrazine olefin oxide polyether (Jiangsu Haian Petrochemical Plant), 25% gas oil, 0.8% corrosion inhibitor alkynyloxymethyl quaternary ammonium salt (Sayangke Ruoxing Chemical), the rest is water.

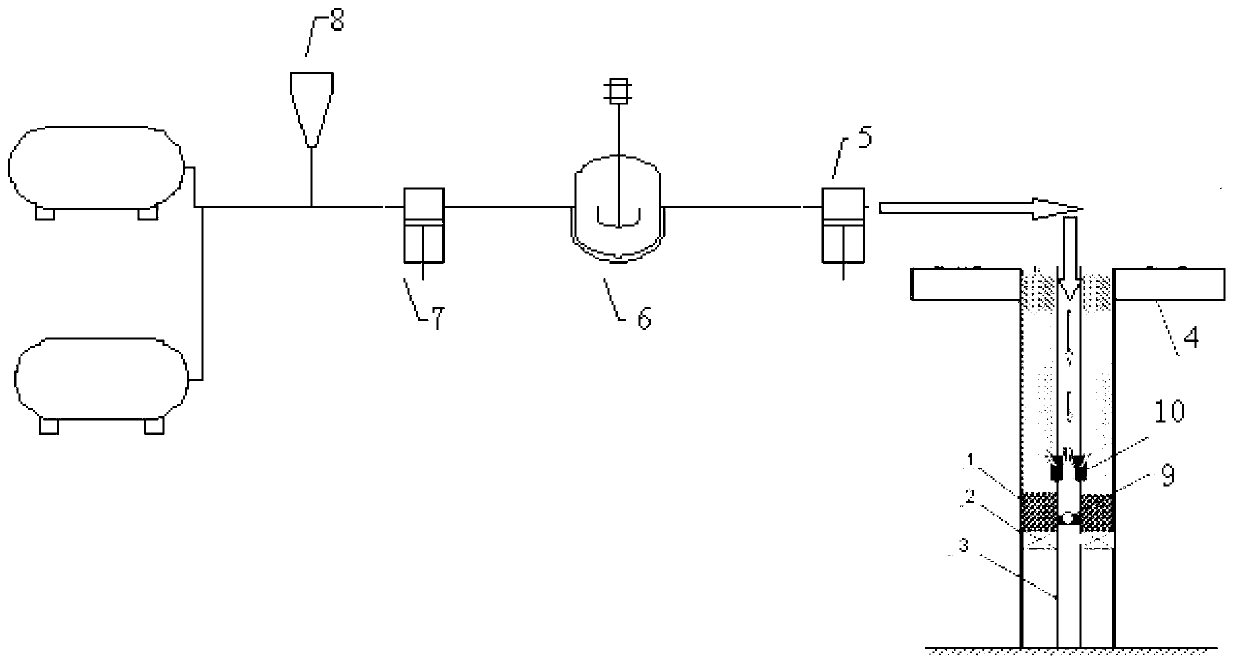

[0038] See figure 2 , Use the dosing pump truck 7 from the dosing port 8 to prepare the liquid in the dosing tank 6 according to the formula, continue to stir the dosing to form a foamy emulsion, and pass inert gas with a uniform phase. Circulating well washing, firstly clean the annulus between tubing 3 and casing 1, and then seal the packer 2. A ball is thrown from the wellhead tubing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap