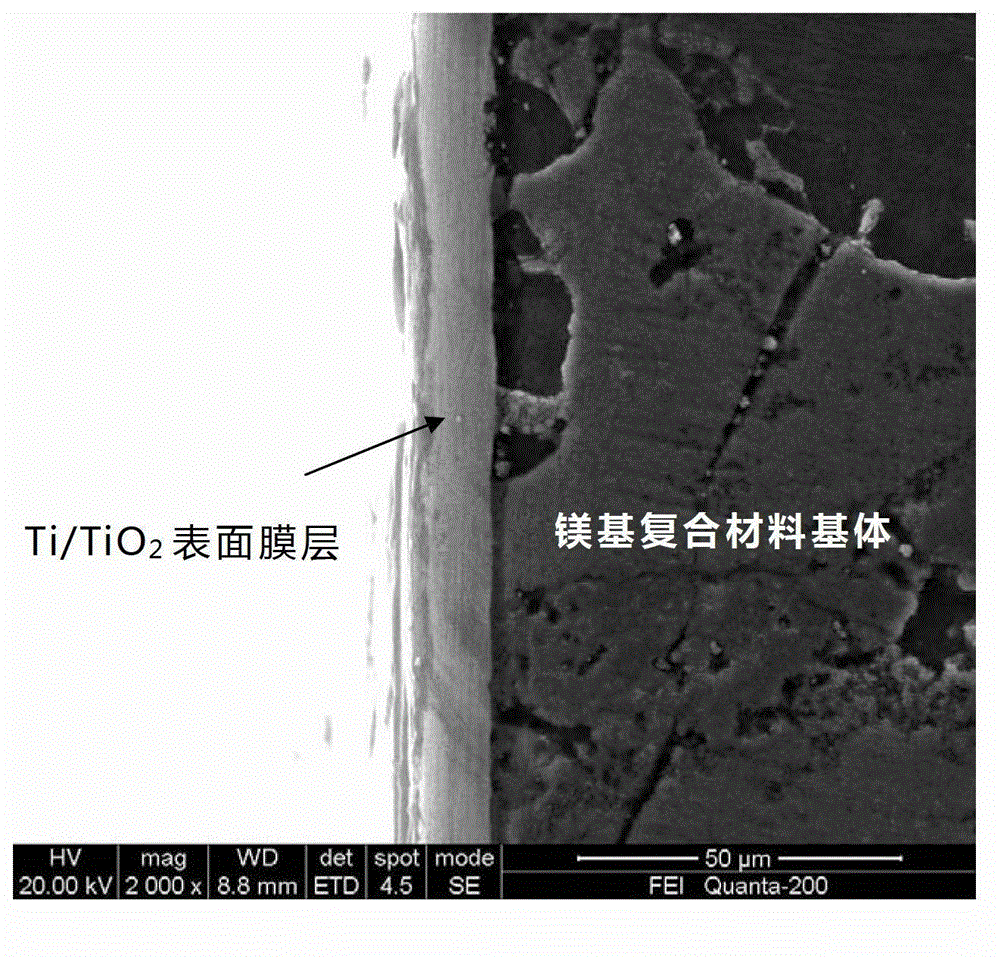

A method for preparing ti/tio2 or tin biocompatible film layer on the surface of magnesium-based composite material

A composite material and film technology, which is applied in metal material coating process, coating, ion implantation plating, etc., can solve the problem that the biocompatibility of the film layer has not been significantly improved, and achieve the reduction of hydrogen precipitation and process The process is short and the effect of delaying the chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composite material with hydroxyapatite particles added to the magnesium matrix is used as the matrix material. Firstly, the magnesium matrix material is polished on sandpaper to remove the surface oxide film layer, and then it is cleaned in absolute alcohol, and then ultrasonic cleaning equipment is added. Hydroalcohol for further cleaning to ensure that the surface of the magnesium matrix material is clean and free of oxides. In the vacuum multi-arc ion plating equipment, the magnesium / hydroxyapatite composite material is coated on the surface. Vacuum the vacuum multi-arc ion coating machine to 6.0×10 -3 Pa vacuum, then heated to 200°C, filled with argon, the partial pressure of argon controlled at 0.5Pa, connected to the bias power of the magnesium substrate, with a bias value of 100V, and initially bombarded the magnesium substrate for 2 minutes. Vacuum again to 3×10 -3 The vacuum degree above Pa, the bias voltage of the magnesium / hydroxyapatite composite mat...

Embodiment 2

[0037] The composite material with tricalcium phosphate particles added to the magnesium matrix is used as the matrix material. First, the magnesium-based composite material is polished on sandpaper to remove the surface oxide film layer, and then cleaned in anhydrous alcohol, and then ultrasonic cleaning equipment is added. Hydroalcohol for further cleaning to ensure that the surface of the magnesium matrix material is clean and free of oxides. Surface coating of magnesium / tricalcium phosphate composites in vacuum multi-arc ion plating equipment. Vacuum the vacuum multi-arc ion coating machine to 6.0×10 -3 The vacuum degree is above Pa, then heated to 200°C, filled with argon, the partial pressure of argon is controlled at 0.5Pa, the bias power of the magnesium substrate is connected, the bias value is 250V, and the magnesium substrate is initially bombarded for 3 minutes; Fill the vacuum chamber with nitrogen, keep the partial pressure of nitrogen at 1Pa, occupying 45% of...

Embodiment 3

[0039] The composite material with hydroxyapatite particles added to the magnesium matrix is used as the matrix material. Firstly, the magnesium matrix material is polished on sandpaper to remove the surface oxide film layer, and then it is cleaned in absolute alcohol, and then ultrasonic cleaning equipment is added. Further cleaning with hydroalcohol ensures that the surface of the magnesium / hydroxyapatite composite is clean and oxide-free. Surface coating is carried out in vacuum multi-arc ion plating equipment. Vacuum the vacuum multi-arc ion coating machine to 6.0×10 -3 The vacuum degree is above Pa, then heated to 210°C, filled with argon, the partial pressure of argon is controlled at 0.4Pa, and the bias power of the magnesium / hydroxyapatite composite material is connected, and the bias value is 250V. Carry out initial bombardment for 3 minutes; vacuum again to 3×10 -3 The vacuum degree above Pa, the bias voltage of the magnesium / hydroxyapatite composite material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com