Integrated composite external-driving type bulging device for vehicle drive axle

An external drive and drive axle technology, applied in vehicle parts, transportation and packaging, metal processing equipment, etc., can solve the problems of complex bulging mechanism and process, less application, high welding requirements, and achieve high blank utilization and production efficiency. , the effect of high strength and stiffness, high fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

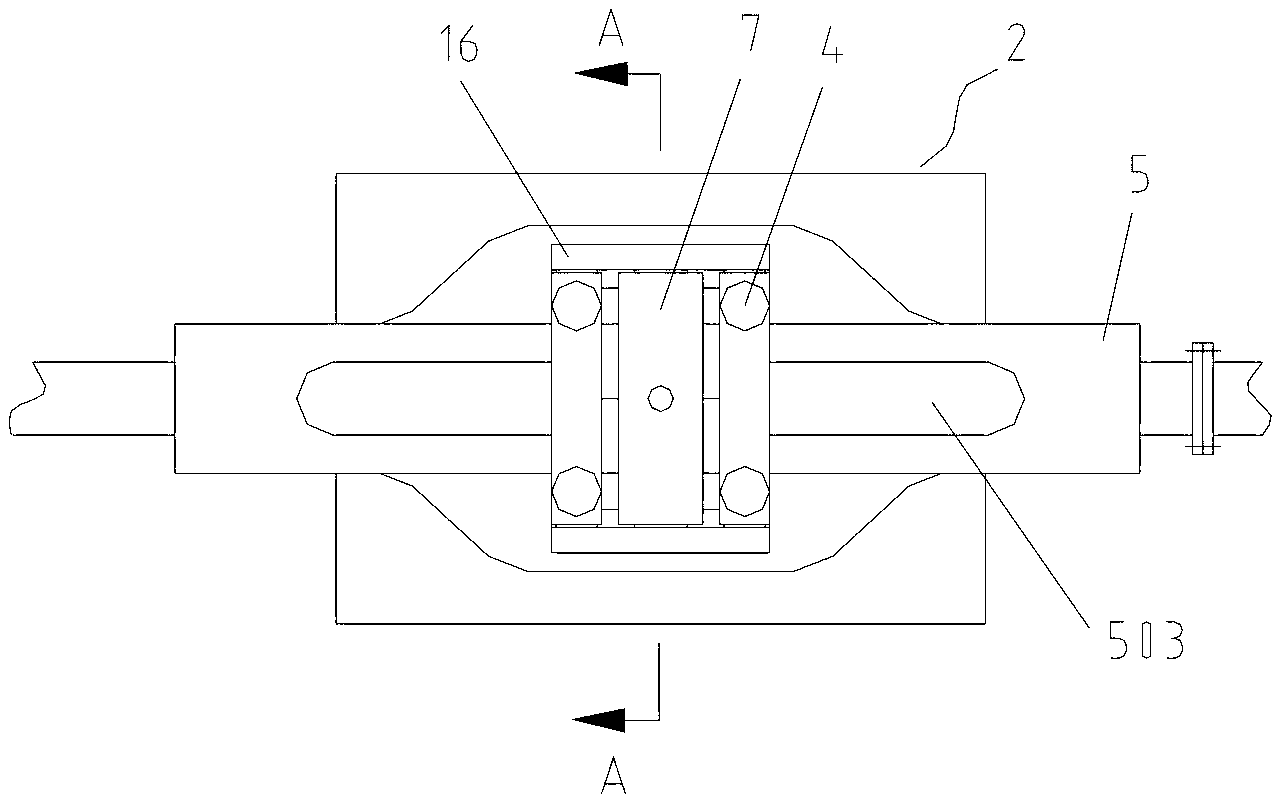

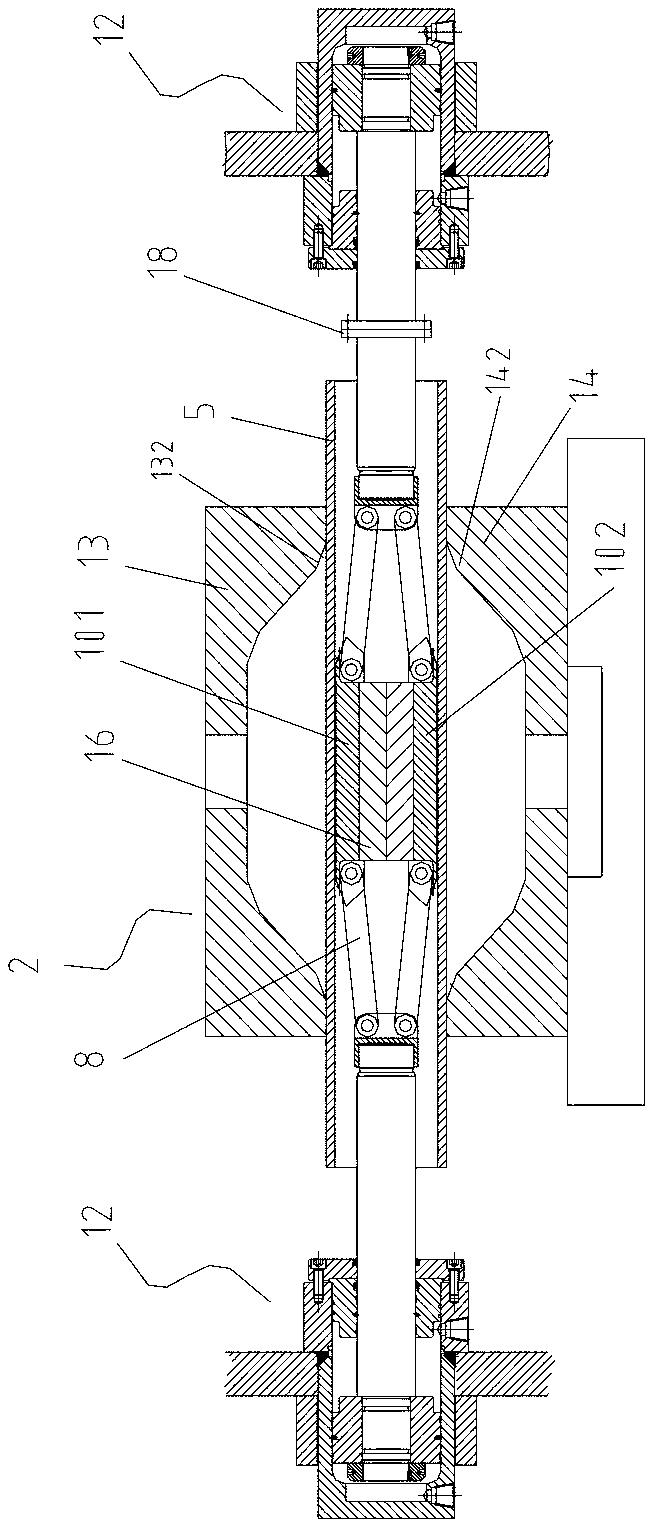

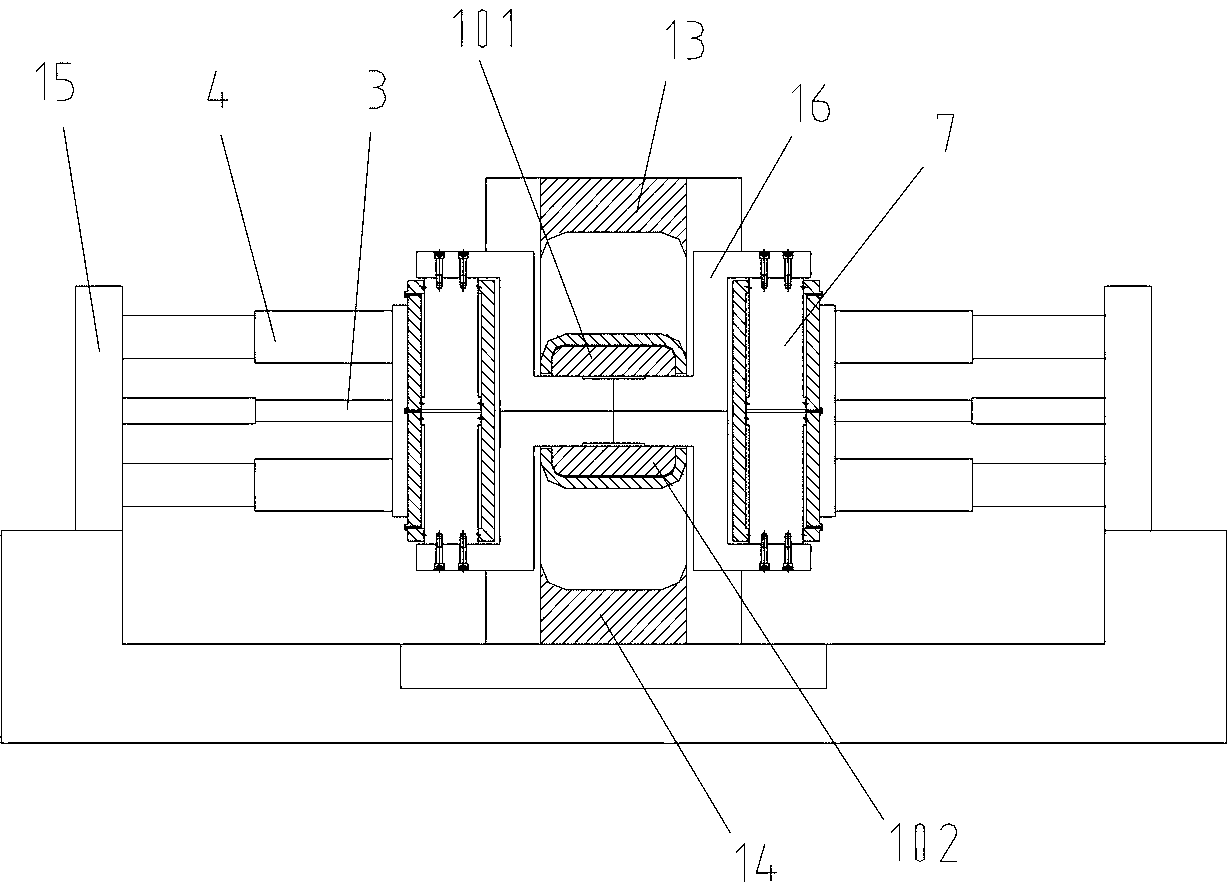

[0058] like Figure 1 to Figure 4 As shown, the overall composite external drive type bulging device of the automobile drive axle of the present invention includes a bulging inner mold 1, a bulging outer mold 2 and an outer driving type bulging force for applying a bulging force to the bulging inner mold 1 generating device.

[0059] like Figure 8 As shown, the axle housing workpiece 5 has an axle housing pipa bag 501 after the machining is completed, and has a transition surface 502 between the bulging deformation zone and the non-deformation zone. like Image 6 As shown, the bulging inner mold 1 includes an upper module 101 and a lower module 102 respectively matched with the upper and lower inner walls of the axle housing pipa bag 501, and the two ends of the upper module 101 and the lower module 102 are respectively hinged with the linkage mechanism.

[0060] The externally driven bulging force generating device includes a pressure generating device and a thrust genera...

Embodiment 2

[0068] like Figure 1 to Figure 4 As shown, the overall composite external drive type bulging device of the automobile drive axle of the present invention includes a bulging inner mold 1, a bulging outer mold 2 and an outer driving type bulging force for applying a bulging force to the bulging inner mold 1 generating device.

[0069] like Figure 8 As shown, the axle housing workpiece 5 has an axle housing pipa bag 501 after the machining is completed, and has a transition surface 502 between the bulging deformation zone and the non-deformation zone. like Image 6 As shown, the bulging inner mold 1 includes an upper module 101 and a lower module 102 respectively matched with the upper and lower inner walls of the axle housing pipa bag 501, and the two ends of the upper module 101 and the lower module 102 are respectively hinged with the linkage mechanism.

[0070] like Figure 9 and Figure 10 As shown, the bulging outer mold 2 of the present embodiment includes a support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com