Automatic sealing device

An automatic sealing and sealing technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of wrong action of the peeling part, cumbersome maintenance, and greatly increased manufacturing costs, and achieve simple structure, simple maintenance, and trust sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

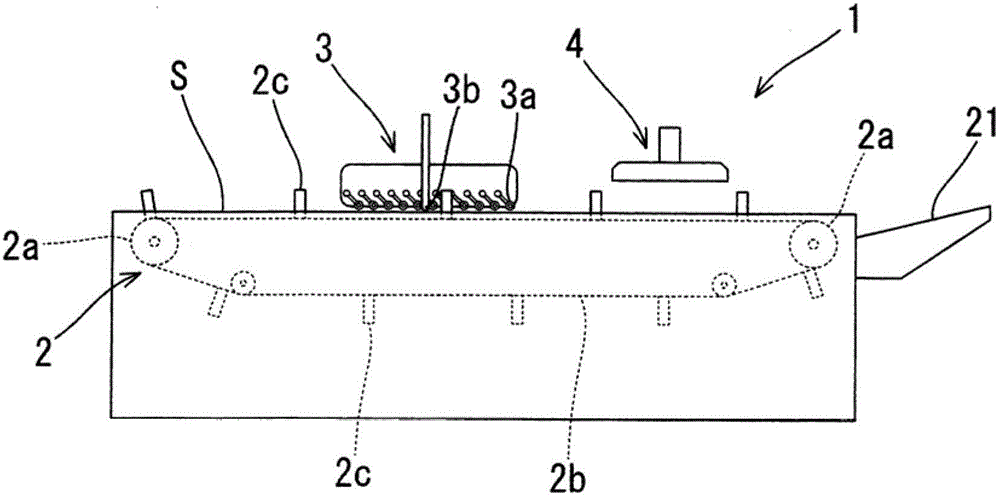

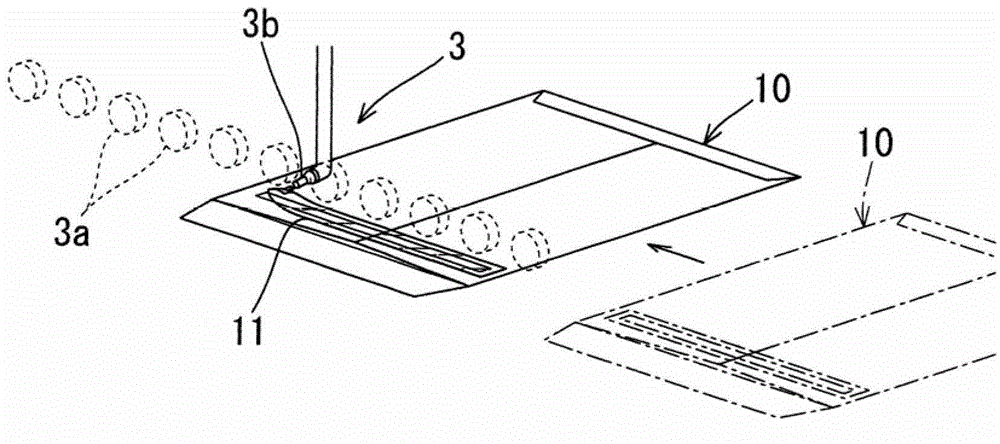

[0042] Hereinafter, an embodiment of the "automatic sealing device" of the present invention will be described with reference to the drawings. Automatic sealing device 1 of the present invention is as figure 1 As shown, it is basically composed of a conveying part 2 , a peeling part 3 and a sealing part 4 .

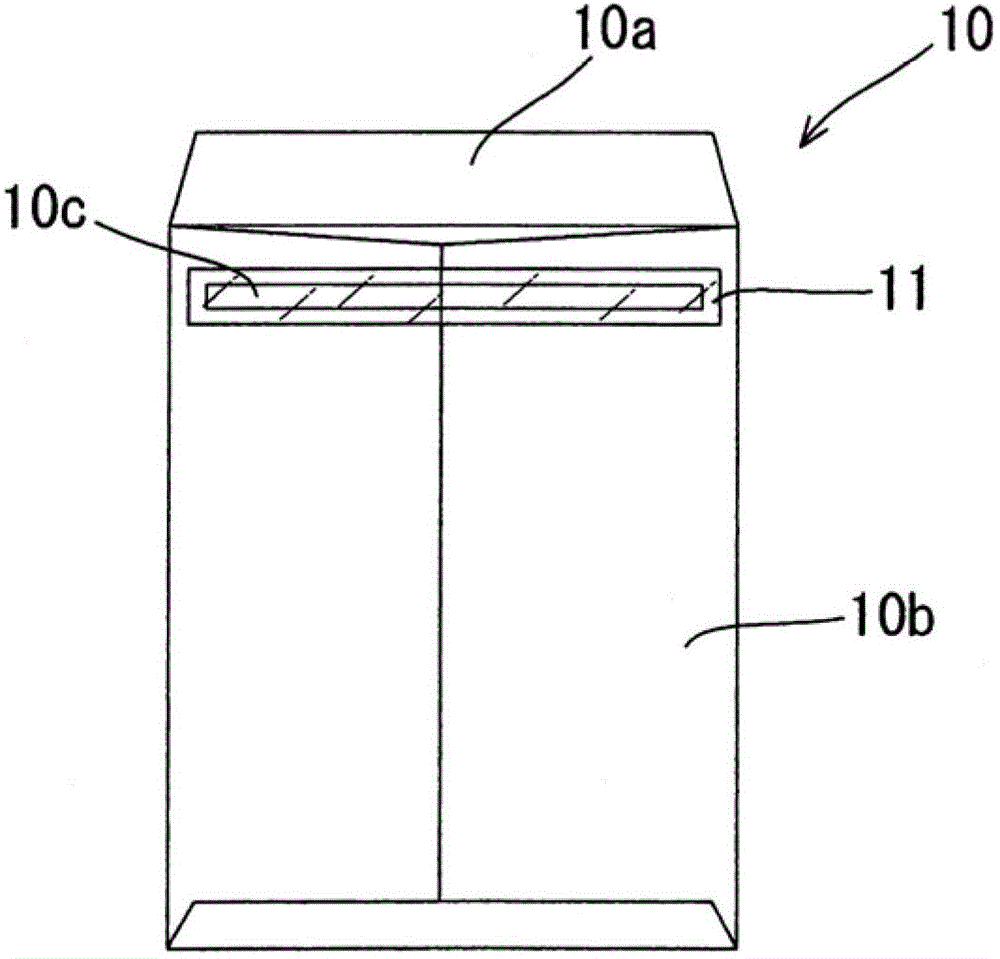

[0043] The conveying part 2 is to figure 2 Envelopes 10 shown, from set position S on the transport table (see figure 1 ), convey to the peeling part 3 and the sealing part 4 in sequence, and finally convey to the device of the paper discharge table 21, the conveying part 2 has: including the roller (drive roller Sub)" a plurality of rollers 2a; and a conveyor belt 2b peripherally arranged on the outside of the roller 2a; and a plurality of conveying claws 2c arranged on the conveyor belt 2b at a specific interval.

[0044] and figure 2 The envelope 10 shown is supplied to the set position S of the conveying part 2 in the following state: the enclosed matter is intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com