Lithium ion battery cathode material and preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and lithium-rich cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of irreversible capacity loss, that is, low first coulombic efficiency, limited commercial application, poor cycle performance, etc., to overcome the problems of coulombic Inefficiency, low cost, effect of electrochemical performance modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] Example 1

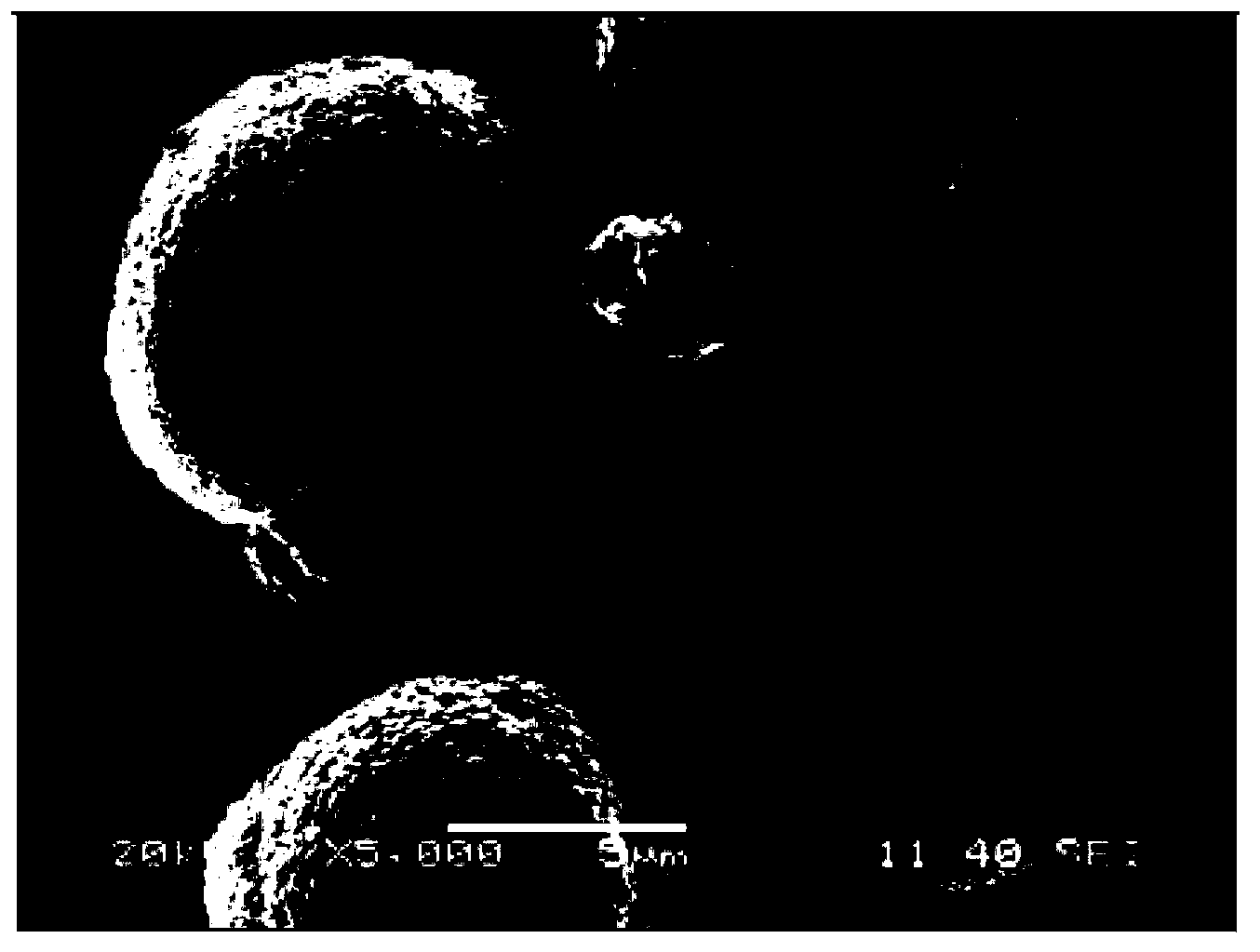

[0042] This embodiment provides a lithium-ion battery cathode material. The structure of the material is a lithium-rich cathode material 0.1Li 2 MnO 3 ·0.9LiNi 0.5 Mn 0.5 O 2 LiNi coated 0.5 Mn 1.5 O 4 , And the structure is a core-shell structure, where the lithium-rich cathode material 0.1Li 2 MnO 3 ·0.9LiNi 0.5 Mn 0.5 O 2 Is the core of the core-shell structure, LiNi 0.5 Mn 1.5 O 4 Is the shell of the core-shell structure, LiNi 0.5 Mn 1.5 O 4 It accounts for 18% of the mass of lithium-ion battery cathode materials.

[0043] The preparation method of the lithium ion battery cathode material in this embodiment includes the following steps:

[0044] (1) According to the molecular formula of lithium-rich cathode material 0.1Li 2 MnO 3 ·0.9LiNi 0.5 Mn 0.5 O 2 The coefficient ratio of Ni:Mn=9:11 is used to prepare a mixed aqueous solution of the first nickel salt nickel nitrate and the first manganese salt manganese nitrate, and the amount ratio of nickel ions to manga...

Example Embodiment

[0059] Example 2

[0060] This embodiment provides a lithium-ion battery cathode material. The structure of the material is 0.3Li 2 MnO 3 ·0.7LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 LiNi coated 0.1 Mn 1.9 O 4 , And the structure is a core-shell structure, in which the lithium-rich cathode material 0.3Li 2 MnO 3 ·0.7LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 Is the core of the core-shell structure, LiNi 0.1 Mn 1.9 O 4 Is the shell of the core-shell structure, LiNi 0.1 Mn 1.9 O 4 It accounts for 16% of the mass of lithium-ion battery cathode materials.

[0061] The method for preparing the positive electrode material of the lithium ion battery in this embodiment includes the following steps:

[0062] (1) According to the molecular formula of lithium-rich cathode material 0.3Li 2 MnO 3 ·0.7LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 The coefficient ratio in Ni:Co:Mn=7:7:16 is used to prepare a mixed aqueous solution of the first nickel salt nickel acetate, the first cobalt salt cobalt acetate and the first manganese salt manganese a...

Example Embodiment

[0070] Example 3

[0071] This embodiment provides a lithium-ion battery cathode material. The structure of the material is 0.4Li 2 MnO 3 ·0.6LiNi 0.5 Co 0.3 Mn 0.2 O 2 LiNi coated 0.4 Mn 1.6 O 4 , And the structure is a core-shell structure, in which the lithium-rich cathode material 0.4Li 2 MnO 3 ·0.6LiNi 0.5 Co 0.3 Mn 0.2 O 2 Is the core of the core-shell structure, LiNi 0.4 Mn 1.6 O 4 Is the shell of the core-shell structure, LiNi 0.4 Mn 1.6 O 4 It accounts for 2% of the mass of lithium-ion battery cathode materials.

[0072] The method for preparing the positive electrode material of the lithium ion battery in this embodiment includes the following steps:

[0073] (1) According to the molecular formula of lithium-rich cathode material 0.4Li 2 MnO 3 ·0.6LiNi 0.5 Co 0.3 Mn 0.2 O 2 The coefficient ratio of Ni:Co:Mn=15:9:26 is used to prepare a mixed aqueous solution of the first nickel salt nickel sulfate, the first cobalt salt cobalt sulfate and the first manganese salt manganese s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap