Pressing machine

A press and fuselage technology, applied in the field of presses, can solve the problems of high cost, enlarged fuselage consumables, and self-heavy weight, and achieve the effects of low production cost, small overall deformation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

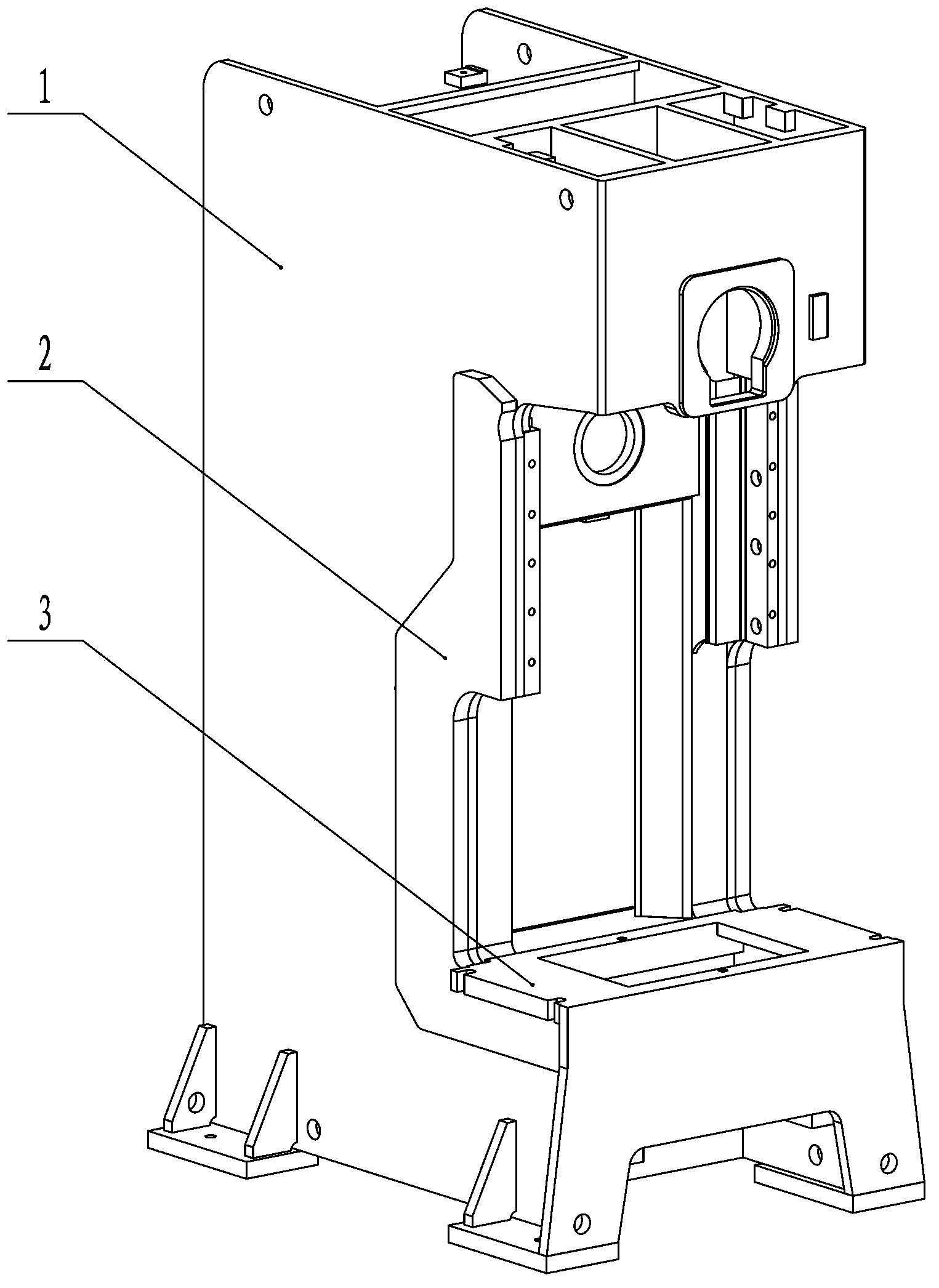

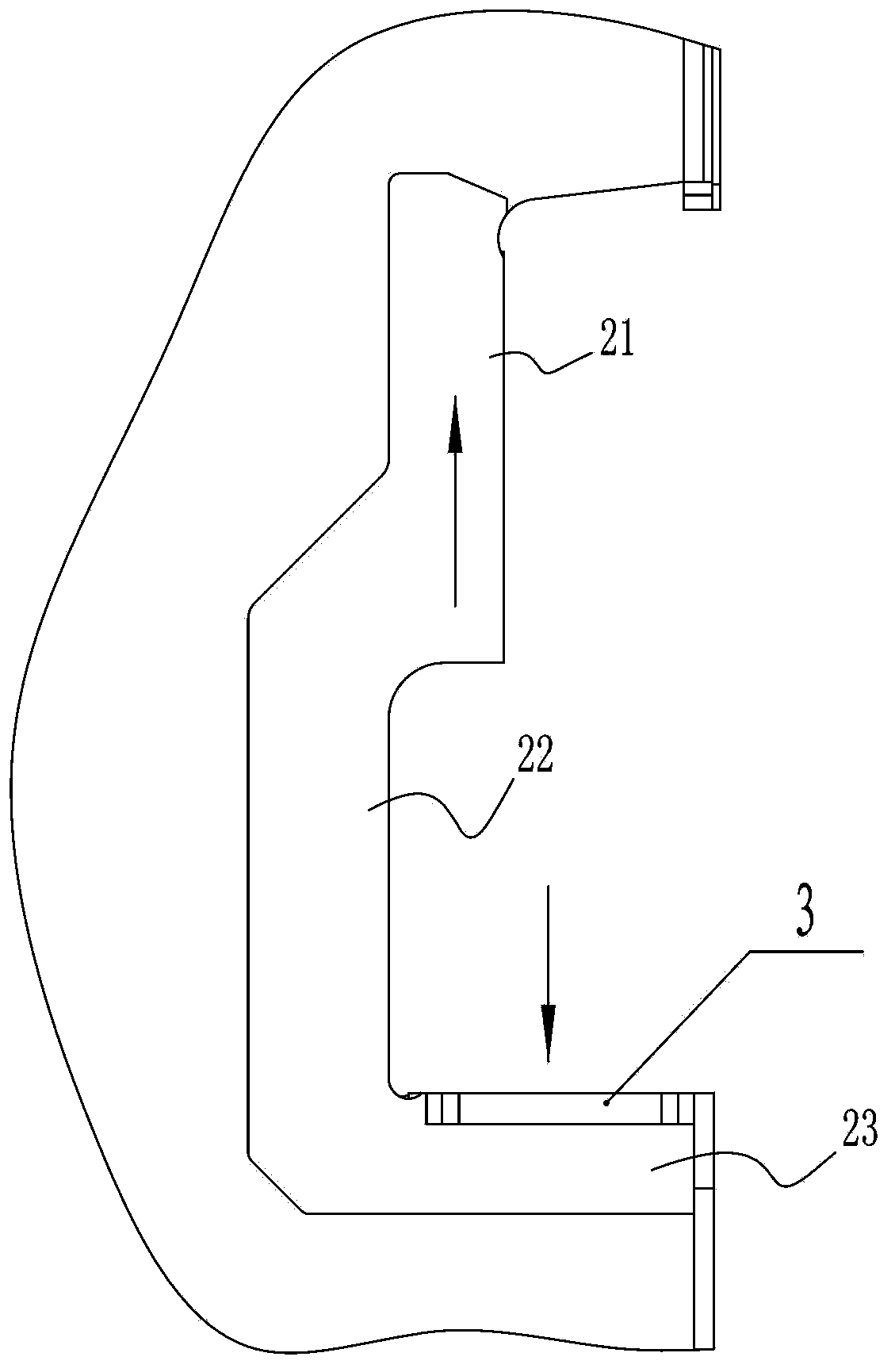

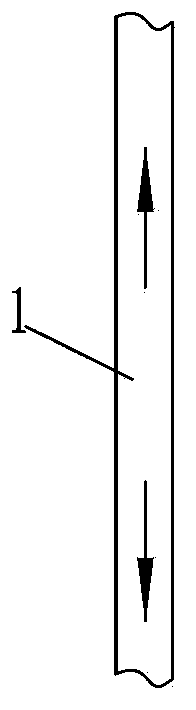

[0018] Such as figure 1 , figure 2 A kind of press machine shown, comprises welded fuselage, and the inside and outside of the left and right wallboards 1 of described welded fuselage are all welded with reinforcing plate 2, and reinforcing plate 2 comprises the guide rail reinforcing part 21 that strengthens guide rail installation area, to The platform reinforcing part 23 that strengthens the area below the working platform 3 and the intermediate reinforcing part 22 that strengthens the wallboard between the guide rail 4 and the working platform 3, the intermediate reinforcing part 22 is integrated with the guide rail reinforcing part 21 and the platform reinforcing part 23. The widths of the guide rail reinforcement part 21 , the platform reinforcement part 23 and the middle reinforcement part 22 of the reinforcement board 2 are all greater than 30 cm. The thickness of the reinforcing plate 2 is greater than that of the left and right wall panels 1 . Guide rails 4 are in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com