Method for prolonging service life of graphite crucible in medium smelting

A graphite crucible and medium smelting technology, applied in the field of medium smelting, can solve the problems of high cost, short service life of graphite crucible, reduced process efficiency, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

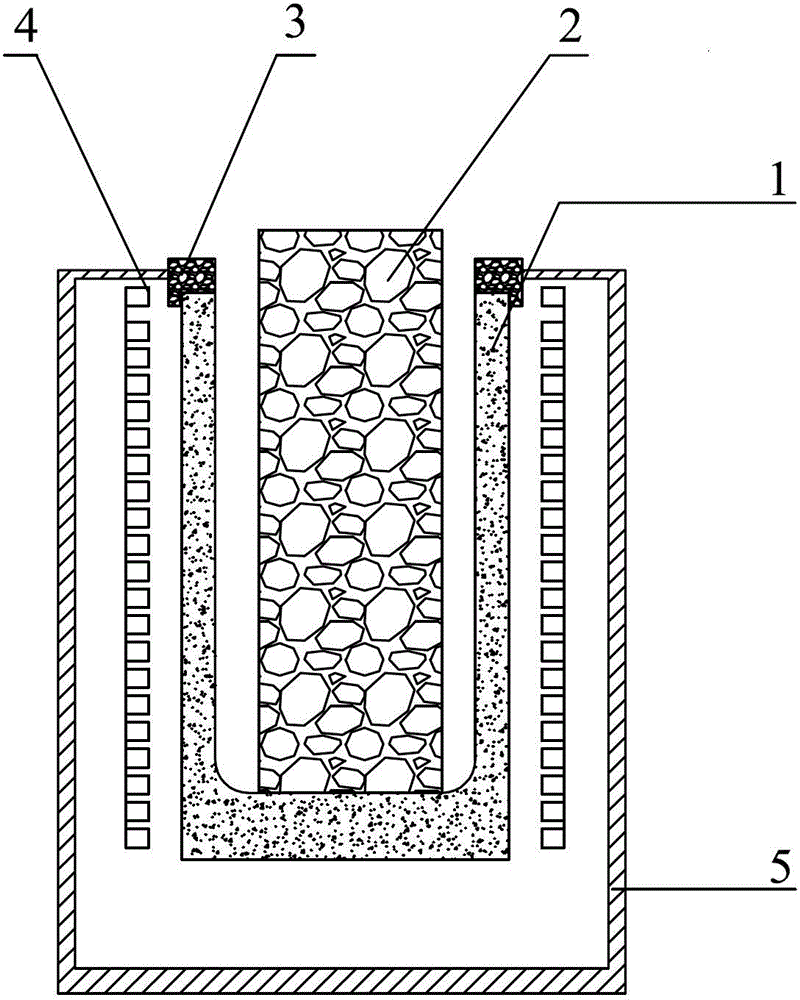

[0025] Graphite crucible 1 has a capacity of 200kg and an inner layer height of 1050mm. Graphite column 2 is a cylinder with a diameter of 195mm and a height of 1200mm. The graphite protection ring 3 is a solid circular structure with a height of 100mm.

[0026] First, the graphite crucible 1 is placed in the furnace body 5, and the induction coil 4 is installed between the graphite crucible 1 and the furnace body 5, the method is as follows:

[0027] (1) First buckle 3 sets of graphite protection rings on the upper edge of the graphite crucible 1, so as to be 100mm higher than the graphite crucible, and then add 50kg of industrial silicon into the graphite crucible 1;

[0028] (2) Turn on the induction coil 4, heat the industrial silicon to melt into silicon liquid, put the graphite column 2 vertically at the central axis of the graphite crucible 1, so that the liquid level of the silicon liquid rises, so that the upper end of the graphite column 2 is higher than the graphite...

Embodiment 2

[0032] Graphite crucible 1 has a capacity of 200kg and an inner layer height of 950mm. Graphite column 2 is a cylinder with a diameter of 290mm and a height of 1200mm. The graphite protection ring 3 is a solid circular structure with a height of 150mm.

[0033] First, the graphite crucible 1 is placed in the furnace body 5, and the induction coil 4 is installed between the graphite crucible 1 and the furnace body 5, the method is as follows:

[0034] (1) First buckle 3 sets of graphite protection rings on the upper edge of the graphite crucible 1, so as to be 150mm higher than the graphite crucible, and then add 60kg of industrial silicon into the graphite crucible 1;

[0035] (2) Turn on the induction coil 4, heat the industrial silicon to melt into silicon liquid, put the graphite column 2 vertically at the central axis of the graphite crucible 1, so that the liquid level of the silicon liquid rises, so that the upper end of the graphite column 2 is higher than the graphite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com