Polyethylene glycol double-alkenyl succinic acid monoalkyl-ester ester and preparation method thereof

A technology of alkenyl succinate monoalkyl ester and polyethylene glycol double, which is applied in the field of steel rolling oil, can solve the problems of complex rolling oil formula, and achieve the problem of complex formula and excellent emulsifying performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

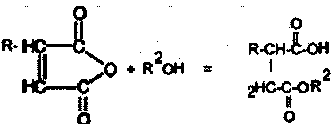

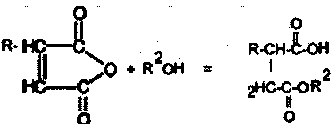

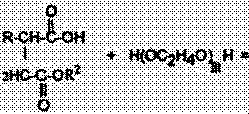

Method used

Image

Examples

Embodiment

[0028] In a three-necked flask with a reflux condenser, add 265 grams of dodecenyl maleic anhydride in a nitrogen atmosphere, add 1% toluenesulfonic acid of the weight of dodecenyl maleic anhydride as a catalyst, then add 186 gram of lauryl fatty alcohol, and 10% dehydrating agent in total, heated up to 115-120°C under stirring, and analyzed the acid value of the reaction system every 0.5 hours during the reaction until the acid value remained unchanged, and the reaction time was 4-5 hour; then add 102 grams of polyethylene glycol (average molecular weight 200), and heat up to 150-160°C under stirring. During the reaction, analyze the acid value of the reaction system every 0.5 hours until the acid value remains unchanged. The reaction time is 6-8 hours, until no water is evaporated, and then the solution is decompressed to make the vacuum of the system reach 0.07-0.08Mpa, and the solvent xylene is evaporated. The product of the reaction is the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com