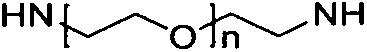

Hydrophilic composite film containing ether groups in surface layer

A composite membrane and hydrophilic technology, which is applied in the direction of membrane technology, semipermeable membrane separation, chemical instruments and methods, etc., can solve the problems of easy pollution and poor hydrophilicity of the surface layer of the composite membrane, so as to improve the service life and improve the hydrophilicity. Water-based, the effect of reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

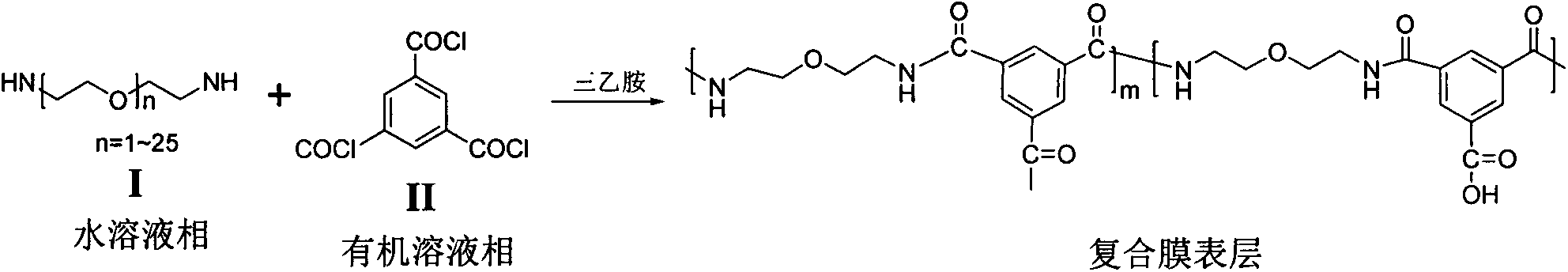

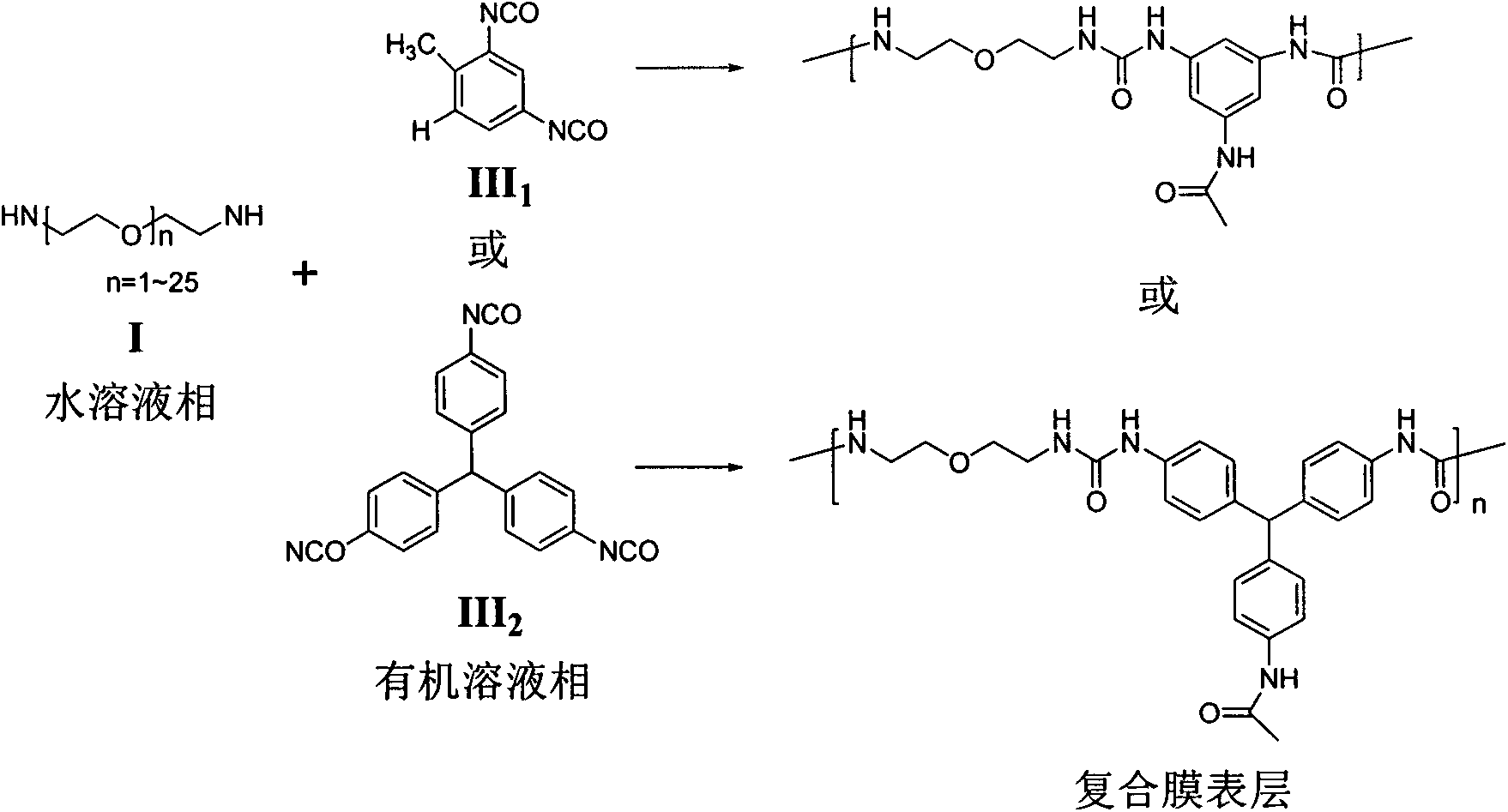

Method used

Image

Examples

Example Embodiment

[0028] Example 1

[0029] Dissolve 15g of double-ended aminodiglycol in 50ml of deionized water, prepare a concentration of 3% (w / v) aqueous solution, add 6g of triethylamine, apply to the surface of the polysulfone flat ultrafiltration membrane basement membrane, and dry in the air . Dissolve 5g of isophthaloyl chloride (II) in 10ml of cyclohexane to prepare a solution with a concentration of 5% (w / v), apply it to the above-mentioned dry surface, let it stand at room temperature for 30 minutes, and place the film on Excess monomers and by-products were removed in deionized water.

Example Embodiment

[0030] Example 2

[0031] Dissolve 6g of double-ended amino diglycol in 20ml of deionized water to prepare an aqueous solution with a concentration of 3% (w / v). Immerse the outer surface of the polyethersulfone hollow fiber microfiltration membrane in this aqueous solution for 10 minutes, take it out and let it dry in the air. Dry. Triisocyanate toluene (III 1 ) 2g was dissolved in 10ml of n-hexane to prepare a solution with a concentration of 2% (w / v). The above-mentioned treated hollow fiber membrane was immersed in it for 2 minutes, and reacted at 40°C for 30 minutes. Deionized water removes excess monomers and by-products.

Example Embodiment

[0032] Example 3

[0033] Dissolve 9g of double-ended aminodiglycol in 30ml of deionized water, and prepare an aqueous solution with a concentration of 3% (w / v), add 6g of triethylamine, coat the surface of the polyvinyl chloride ultrafiltration membrane base membrane, and dry in the air . Triphenylmethane triisocyanate (III 2 ) 7g was dissolved in 10ml of n-hexane to prepare a solution with a concentration of 7% (w / v), coated on the above-mentioned dried surface, and placed at a temperature of 30°C for 20 minutes, and the membrane was placed in deionized water to remove excess monomers and by-products.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap