Method for removing phosphorus from town sewage by recycling waste sludge of water supply plant

A technology for urban sewage and waste mud, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc., can solve the problem of removal rate of only 10-30%, and reduce disposal Cost, low cost, easy to obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using waste sludge from a water supply plant as raw material, the contents of iron and aluminum in the waste sludge are 133 and 98mg / L respectively, and the surface area is 56.11m 2 / g. The waste sludge from the water supply plant was naturally air-dried, crushed, ground and mixed to obtain a powder adsorbent with a particle size of 0.18 mm.

[0024] Urban sewage is taken from three sewage treatment plants with phosphorus concentrations of 5, 10 and 20 mg / L respectively.

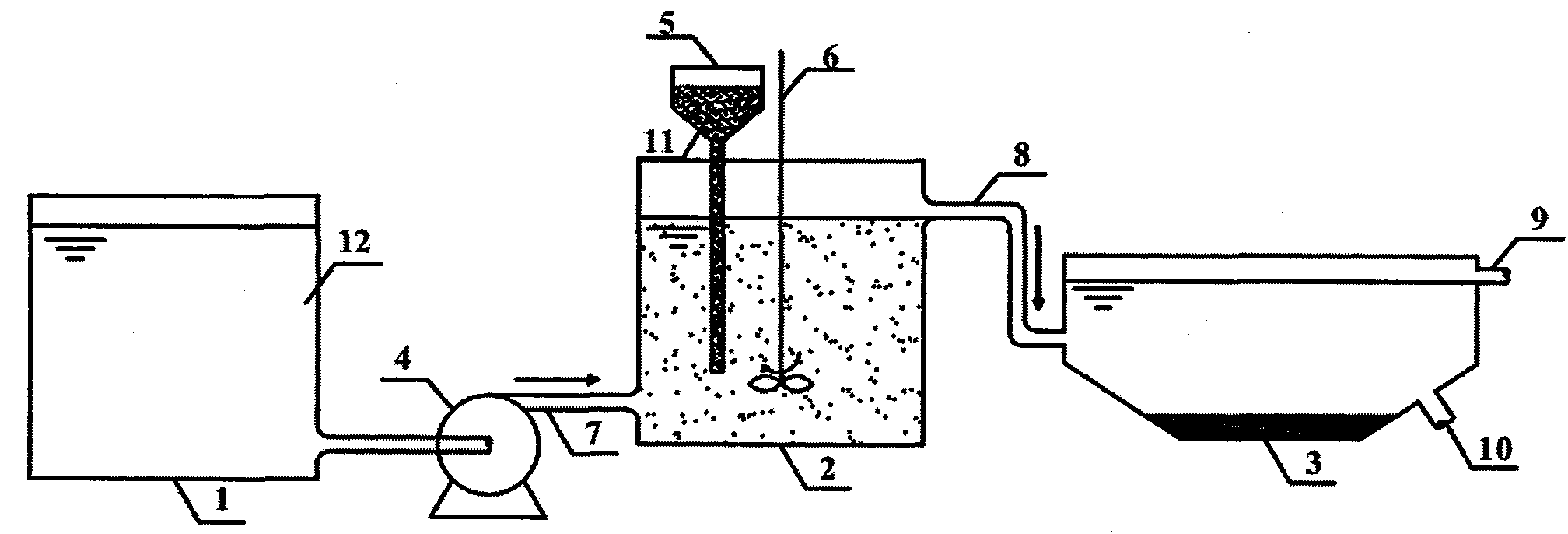

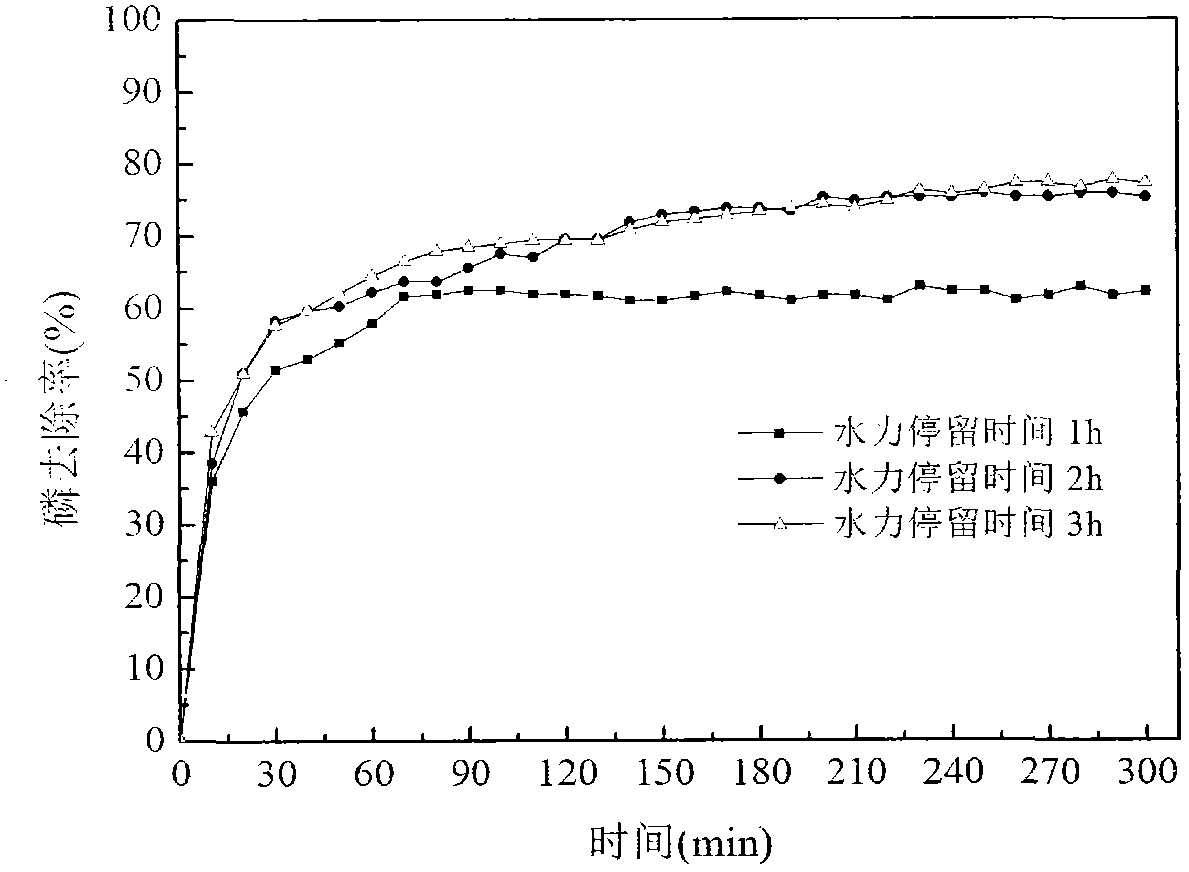

[0025] according to figure 1 Set up three CSTR devices, choose urban sewage with a phosphorus concentration of 10mg / L as the influent water, add 5g / L of waste sludge to the water supply plant, adjust the influent flow rate to control the hydraulic retention time to 1, 2 and 3h respectively, and run Measure the phosphorus concentration in the water in the sedimentation zone every 10 minutes within 5 hours.

[0026] like figure 2 As shown, the phosphorus concentration in the effluent at all hydraul...

Embodiment 2

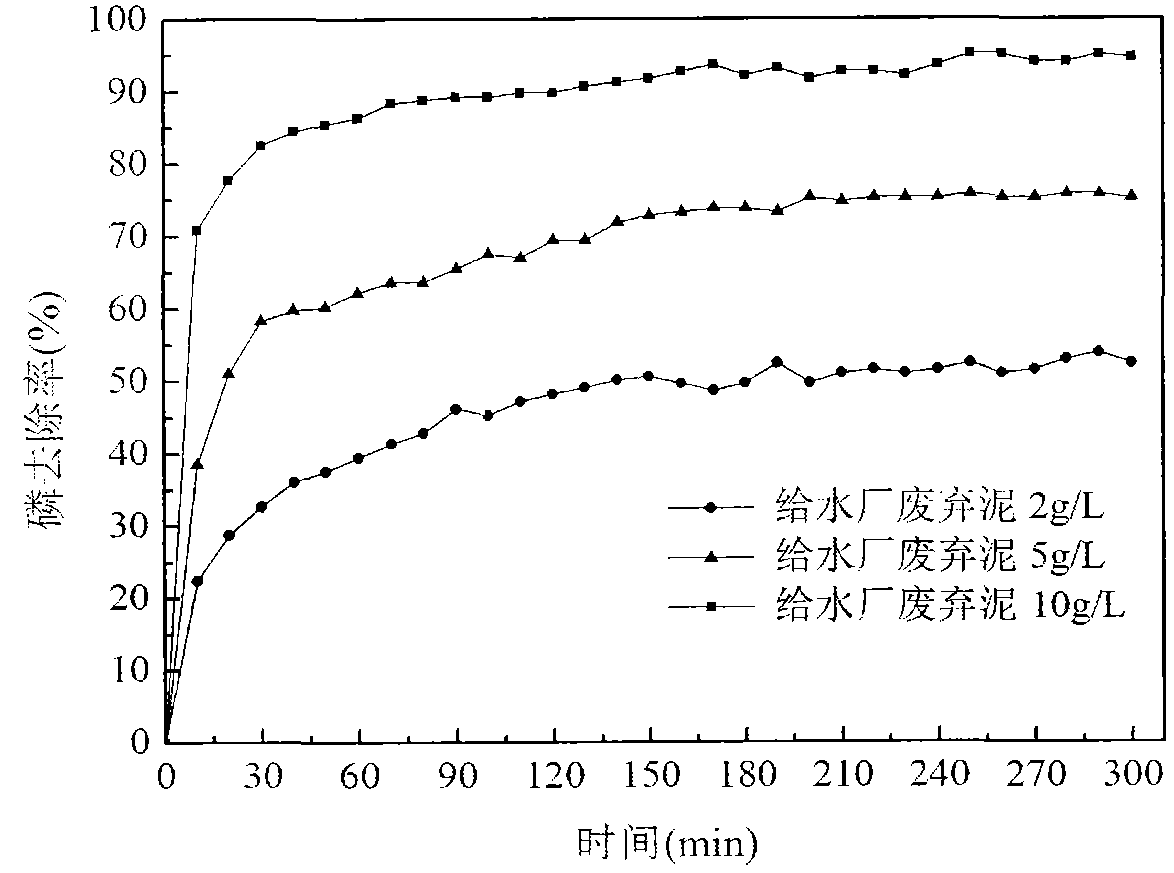

[0028] according to figure 1 Set up three CSTR devices, choose urban sewage with a phosphorus concentration of 10mg / L as influent water, control the residence time of 2h, add different amounts of waste sludge from water supply plants (2, 5, 10g / L), and run within 5h Measure the phosphorus concentration in the water in the sedimentation zone every 10 minutes.

[0029] like image 3 , the concentration of phosphorus in the effluent decreased rapidly at the beginning of all dosages, and then gradually reached equilibrium. The dosage increased from 2 to 10g / L, and the phosphorus removal rate increased from 52.6% to 94.7%. The results show that the phosphorus removal rate of the present invention can be significantly improved by increasing the dosage of waste sludge from water supply plants.

Embodiment 3

[0031] according to figure 1 Set up three CSTR devices, select urban sewage with a phosphorus concentration of 5, 10 and 20 mg / L as influent water, control the hydraulic retention time of the CSTR device to 2 hours, and add 5 g / L of waste sludge to the water plant. Within 5 hours of operation, every Measure the phosphorus concentration in the water in the sedimentation zone every 10 minutes.

[0032] like Figure 4 , the phosphorus concentration in the effluent at all phosphorus concentrations decreased rapidly at the beginning, and then gradually reached equilibrium. The influent phosphorus concentrations were 5, 10 and 20mg / L, and the phosphorus removal rates were 91%, 75% and 68%, respectively. Therefore, the present invention also has better removal efficiency for high-concentration urban sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com