A kind of preparation technology of vancomycin crystal

A vancomycin and preparation process technology, applied in the field of vancomycin crystallization preparation technology, can solve the problems of difficult filtration of precipitation, deep pigment in precipitation, fine particle size of precipitation, etc., and achieves easy filtration, simple preparation process operation, and avoidance of pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Amycolatopsis orientalis is selected as the production strain, and glucose, cottonseed protein powder and inorganic salts are used as fermentation raw materials to produce vancomycin by fermentation, aeration, agitation and intermediate feeding; After 200h, the fermentation was finished, and the tank was put in, and the concentration of vancomycin in the fermented liquid was 15.13g / L.

[0021] After the vancomycin fermentation broth is microfiltered through a ceramic membrane, it is adsorbed by a polystyrene-based sulfonic acid type strongly acidic cation exchange resin, and eluted with a pH 10 sodium hydroxide solution at a rate of 1 column bed volume / hour , the volume of the eluate was 0.5 times the column volume, and 11L of high-concentration vancomycin eluate was obtained (the concentration of vancomycin was 47.71g / L, the total product was 524.88g, and the purity of vancomycin in liquid phase was 83.4%). Liquid color is black. Use concentrated phosphoric acid to ad...

Embodiment 2

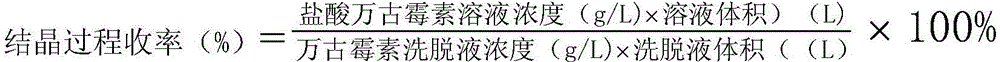

[0026] Produce vancomycin by fermentation method of example 1. After the vancomycin fermentation broth is microfiltered through a ceramic membrane, it is adsorbed by a polystyrene-based sulfonic acid type strongly acidic cation exchange resin, and eluted with a pH 11 sodium hydroxide solution at a rate of 1 column bed volume / hour , the volume of the eluate was 0.5 times the column volume, and 2200L of high-concentration vancomycin eluate was obtained (the concentration of vancomycin was 25.37g / L, the total product was 55.8kg, and the liquid phase purity was 83.4%). The color of the eluate was black. Add 264kg urea to the eluent storage tank (the concentration of urea in the eluent is 120g / L); after stirring and dissolving, filter it with a pipeline filter; quickly adjust the pH of the obtained filtrate to 8.9 with 3mol / L NaOH solution, and then let it stand For crystallization, resuspend and stir the crystals every 2 hours. After 24 hours of crystallization, the crystals wer...

Embodiment 3

[0028] The influence of the amount of urea added on the crystallization yield of vancomycin was investigated. Get the high-concentration vancomycin eluate (wherein the vancomycin concentration is 35.13g / L, liquid phase purity 86.4%) prepared by the method of Example 1, the eluate color is black. Take 5 parts of the above eluent, each 1L, add urea to the concentration of 0, 40, 80, 120, 140g / L respectively; stir and dissolve, filter with filter paper; quickly adjust the pH of the clarified filtrate to 8.5 with 3mol / L NaOH solution After standing still for crystallization, the crystals were resuspended and stirred every 2 hours. After 24 hours of crystallization, the crystals were harvested by filtration with filter paper. The obtained crystals were dissolved with hydrochloric acid aqueous solution, and the purity of the crystal solution was analyzed by high performance liquid chromatography. The effect of urea addition on the vancomycin crystallization yield is shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com