Multifunctional corrosivity test platform for filtering materials

A test platform and multi-functional technology, applied in the analysis of suspensions and porous materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc., to achieve the effects of low failure rate, convenient maintenance and repair, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

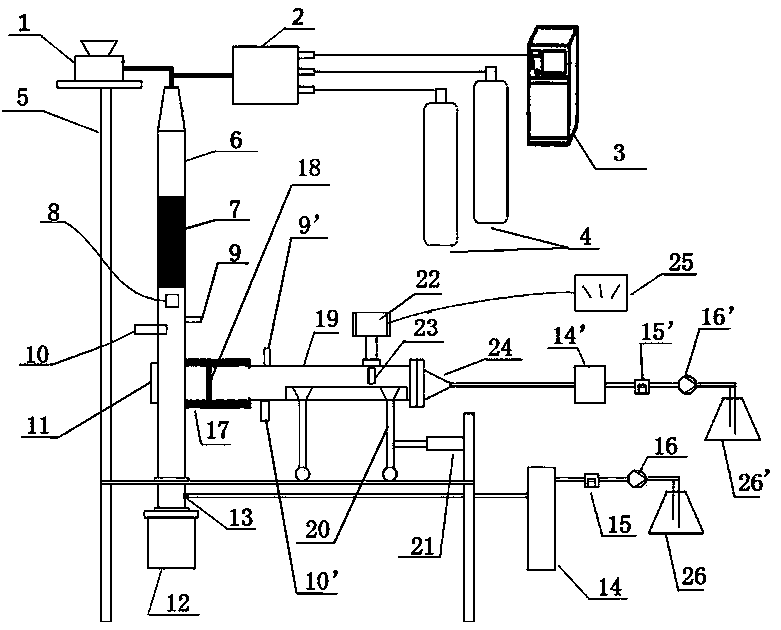

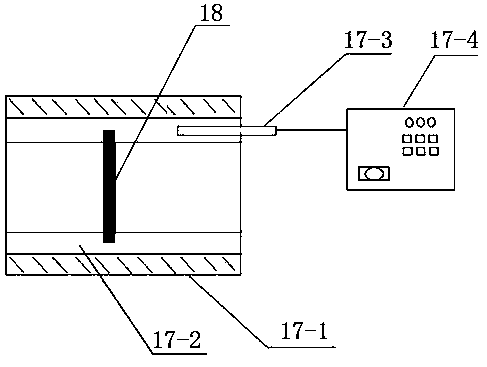

[0021] A multifunctional filter material corrosion test platform, such as figure 1 As shown, it includes a sample holding device 17 and a smoke supply device, a raw smoke channel 6 and a smoke cleaning channel 19 connected in sequence.

[0022] The smoke supply device includes an aerosol generator 1, a gas distribution device 2, an ozone generator 3 and two 2 and O 2 The gas cylinder 4, the gas cylinder 4 and the ozone generating device 3 are all connected to the gas distribution device 2, and the gas distribution device 2 is connected in parallel with the aerosol generator 1 and then passes into the original smoke passage 6.

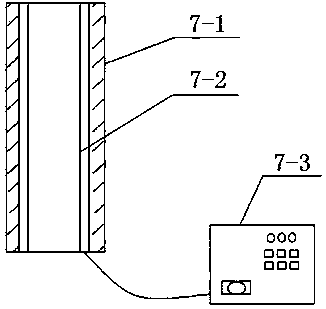

[0023] The original smoke channel 6 is vertically fixed on the platform support 5, the upper part of the original smoke channel 6 is a detachable discharge module 7, the lower p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap