Stretcher jaw clamping device and mounting method thereof

A fixture device and fixture technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of increased project cost investment, potential safety hazards, and high labor intensity, so as to reduce the difficulty and labor intensity of operations, and eliminate potential safety hazards. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

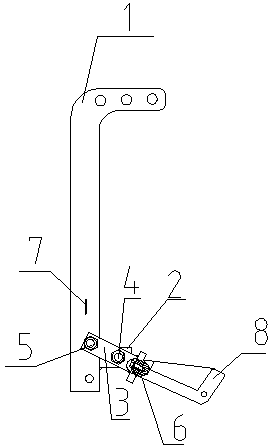

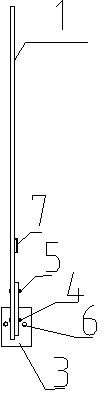

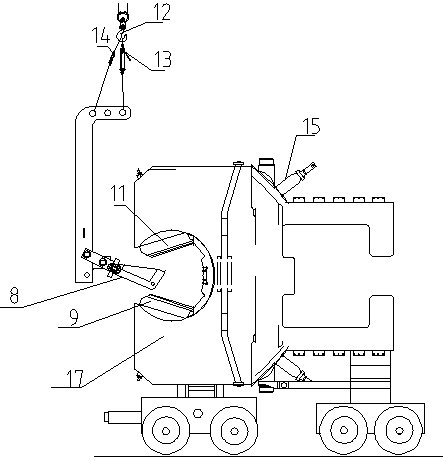

[0019] In the figure, the stretching machine jaw clamp device of the present invention is mainly composed of a boom 1, a support arm 2, a rotating arm 3, a rotating bolt 4, a fixing bolt 5, a connecting bolt 6, a handrail 7, a lower jaw clamp 8, a lower Jaw clamp base 9, upper jaw clamp 10, upper jaw clamp base 11, lifting hook 12, first chain hoist 13, second chain hoist 14, working oil cylinder 15, working wire rope 16, large C-type Block plate 17 forms.

[0020] The device includes a boom 1, a support arm 2, and a rotating arm 3. The upper end of the boom 1 is provided with a hoisting hole, and the lower end is fixedly connected with a support arm 2. The support arm 2 is provided with a rotating bolt 4. The arm 2 is articulated through the rotating bolt 4 and the middle part of the rotating arm 3 , one end of the rotating arm 3 is connected with the boom 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com