Proportional pressure reducing valve

A constant-proportion pressure reducing valve and valve body technology, applied in the field of pressure reducing valves, can solve the problems of high noise, unstable pressure reduction, and large vibration, and achieve the effects of reasonable structure, reliable performance, and low vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below with reference to the embodiments and the accompanying drawings.

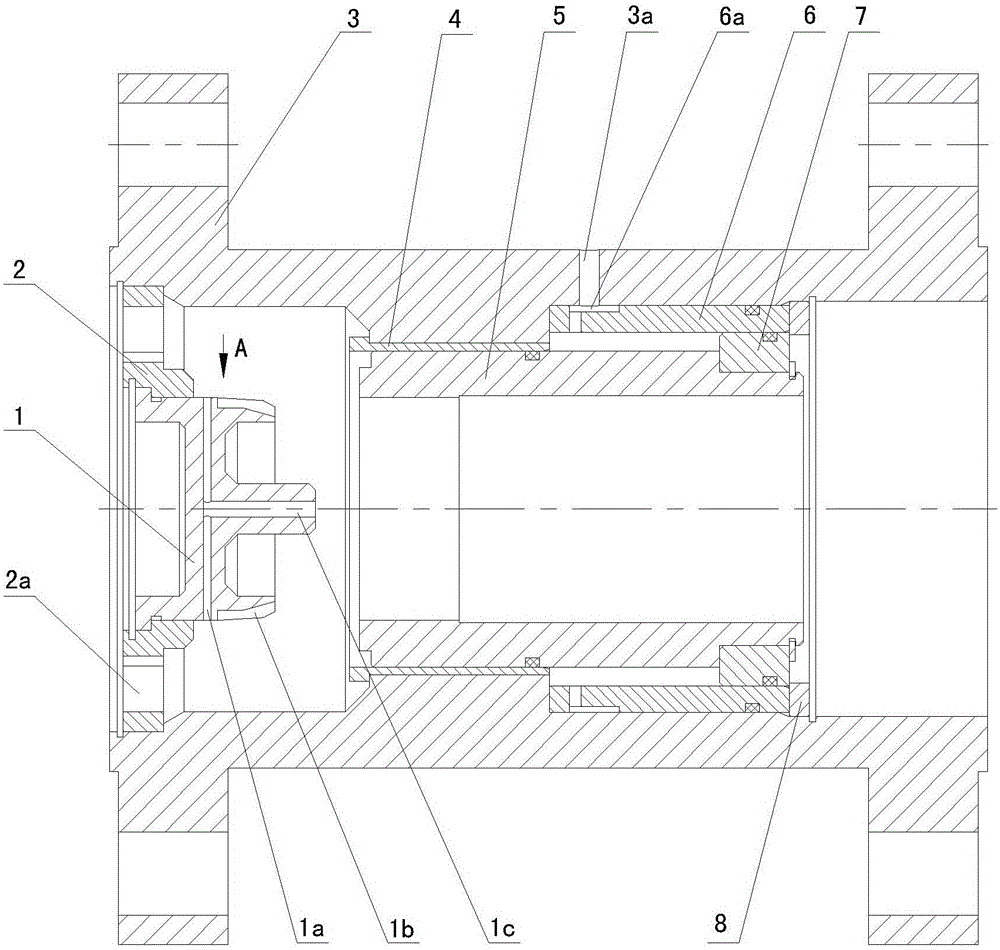

[0010] see figure 1

[0011] The proportional pressure reducing valve provided by the present invention has a valve body 3, a movable hollow piston 5 is arranged in the valve body 3, the physical area of the water inlet end of the piston 5 is smaller than that of the water outlet end, and a water inlet end of the valve body 3 is provided with a The water distribution plate 2 is provided with a water inlet hole 2a on the water distribution plate 2. The guide column 1 installed on the water distribution plate 2 is opposite to the piston 5, and the two are in a plug-fit relationship.

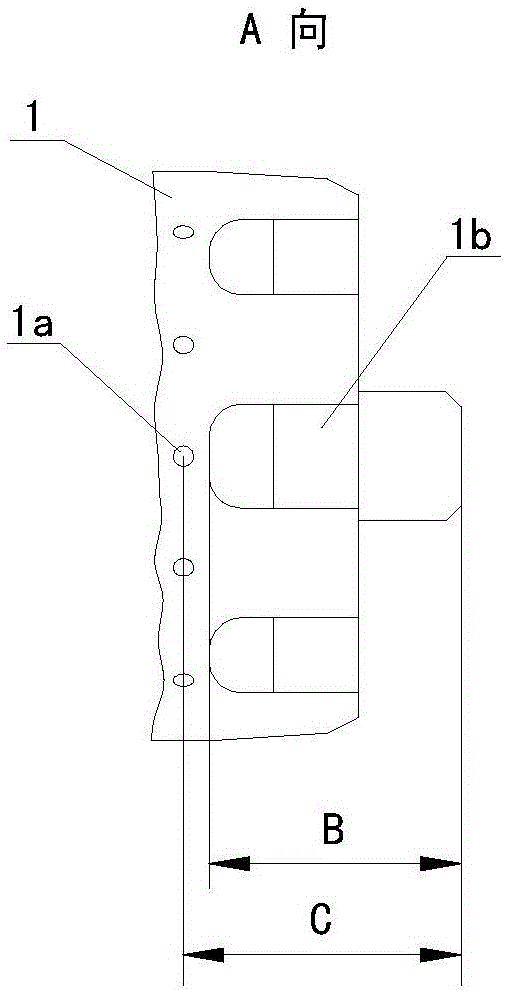

[0012] see figure 1 , figure 2

[0013] There are two or more drainage grooves 1b on the outer surface of the guide column 1. One end of the drainage groove 1b is closed, and the other end penetrates the front end of the guide column 1. A drainage channel 1c and a draina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com