Preparation method of magnetic graphene based oil absorption foam material

A magnetic graphene and graphene-based technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of easy collapse, high price, and complicated operation, and achieve the effect of stable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

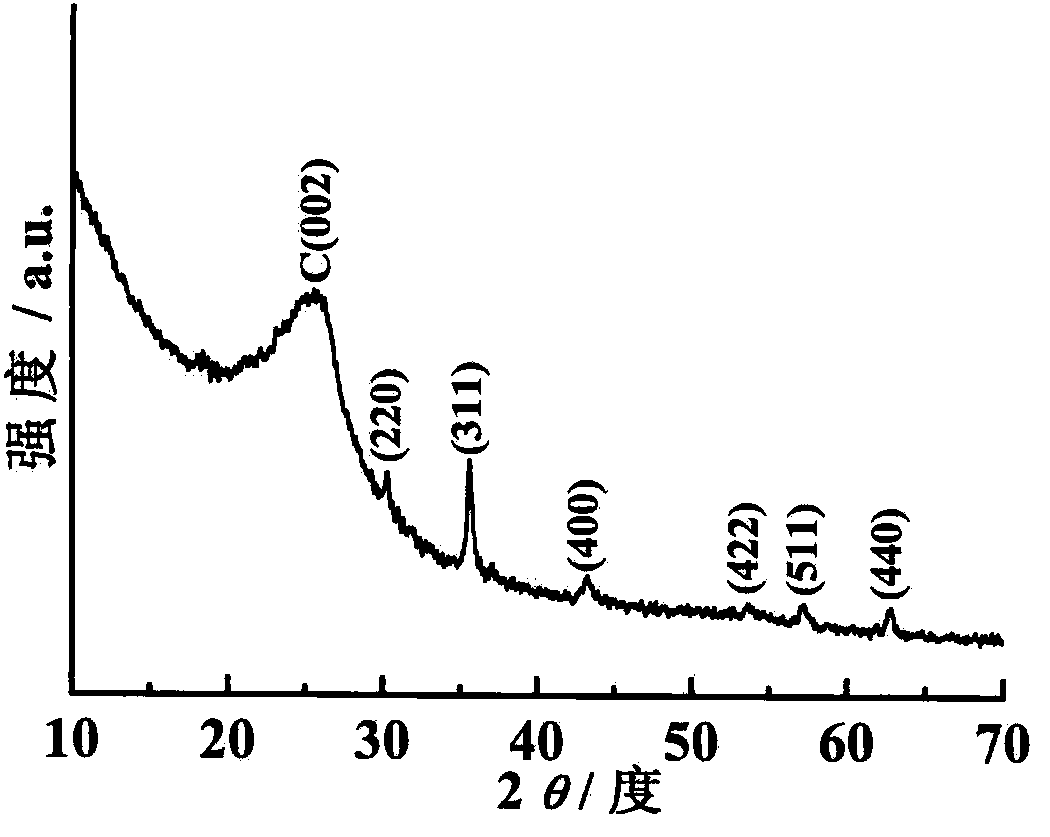

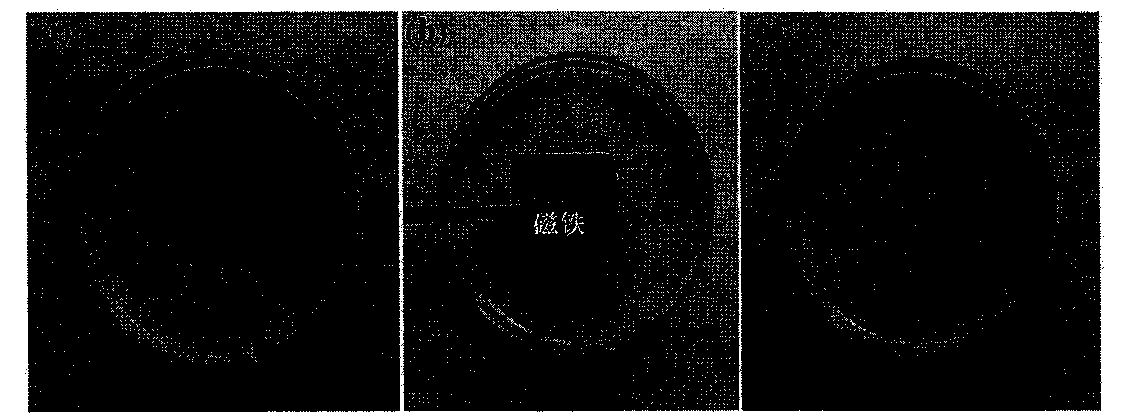

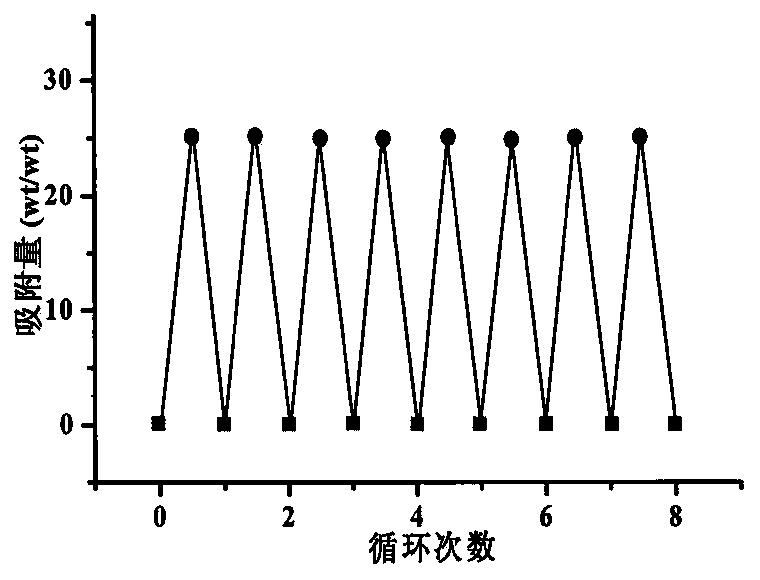

Image

Examples

Example Embodiment

[0024] Example 1

[0025] Using natural flake graphite as raw material, the modified Hummers method is used for oxidation, and then the graphite oxide is peeled off by the ultrasonic method to obtain graphene oxide. The specific steps are:

[0026] In a round-bottom flask, add 50 mL of concentrated sulfuric acid and heat to a temperature of 80 ℃, add 10 g of potassium persulfate and 10 g of phosphorus pentoxide, then slowly add 10 g of natural flake graphite, stir evenly, at a temperature of 80-90 ℃ After keeping for 4 hours, cool to room temperature, dilute with deionized water, then vacuum filter, wash, and dry to obtain pre-oxidized graphite powder;

[0027] Add 230 mL of concentrated sulfuric acid and 5 g of the obtained pre-oxidized graphite powder to the beaker, then add 30 g of potassium permanganate to the beaker in batches, and then keep it in a water bath at 38°C for 2 hours, dilute with deionized water, and stir. Add 50 mL of 30% hydrogen peroxide to obtain a bright yello...

Example Embodiment

[0031] Example 2

[0032] Using natural graphite powder as raw material, the modified Hummers method is used for oxidation, and then the graphite oxide is peeled off by the ultrasonic method to obtain graphene oxide. The specific steps are as follows:

[0033] In a round bottom flask, add 50 mL of concentrated sulfuric acid and heat it to a temperature of 85°C. Add 10g of potassium persulfate and 10g of phosphorus pentoxide, then slowly add 10g of natural graphite powder, stir well, and keep at the temperature of 80-90°C. After 4 hours, cool to room temperature, dilute with deionized water, then vacuum filter, wash, and dry to obtain pre-oxidized graphite powder;

[0034] Add 230 mL of concentrated sulfuric acid and 5 g of the obtained pre-oxidized graphite powder to the beaker, then add 30 g of potassium permanganate to the beaker in batches, and then keep it in a water bath at 38°C for 2 hours, dilute with deionized water, and stir. Add 50 mL of 30% hydrogen peroxide to obtain a b...

Example Embodiment

[0038] Example 3

[0039] Using natural graphite powder as raw material, the modified Hummers method is used for oxidation, and then the graphite oxide is peeled off by the ultrasonic method to obtain graphene oxide. The specific steps are as follows:

[0040] In a round-bottom flask, add 50 mL of concentrated sulfuric acid and heat to a temperature of 90°C, then add 10g of potassium persulfate and 10g of phosphorus pentoxide, then slowly add 10g of natural graphite powder, stir evenly, and keep the temperature at 80-90°C After 4 hours, cool to room temperature, dilute with deionized water, then vacuum filter, wash, and dry to obtain pre-oxidized graphite powder;

[0041] Add 230 mL of concentrated sulfuric acid and 5 g of the obtained pre-oxidized graphite powder to the beaker, then add 30 g of potassium permanganate to the beaker in batches, and then keep it in a water bath at 38°C for 2 hours, dilute with deionized water, and stir. Add 50 mL of 30% hydrogen peroxide to obtain a b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap