Liquid spraying device for covered edges of assembly

The technology of a liquid spraying device and a liquid adding device is applied to the device and coating of the surface coating liquid, which can solve the problems of affecting the production efficiency of the production line, uneven lubricating liquid, and waste of the lubricating liquid, so as to improve the market competitiveness. , Improve production efficiency and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

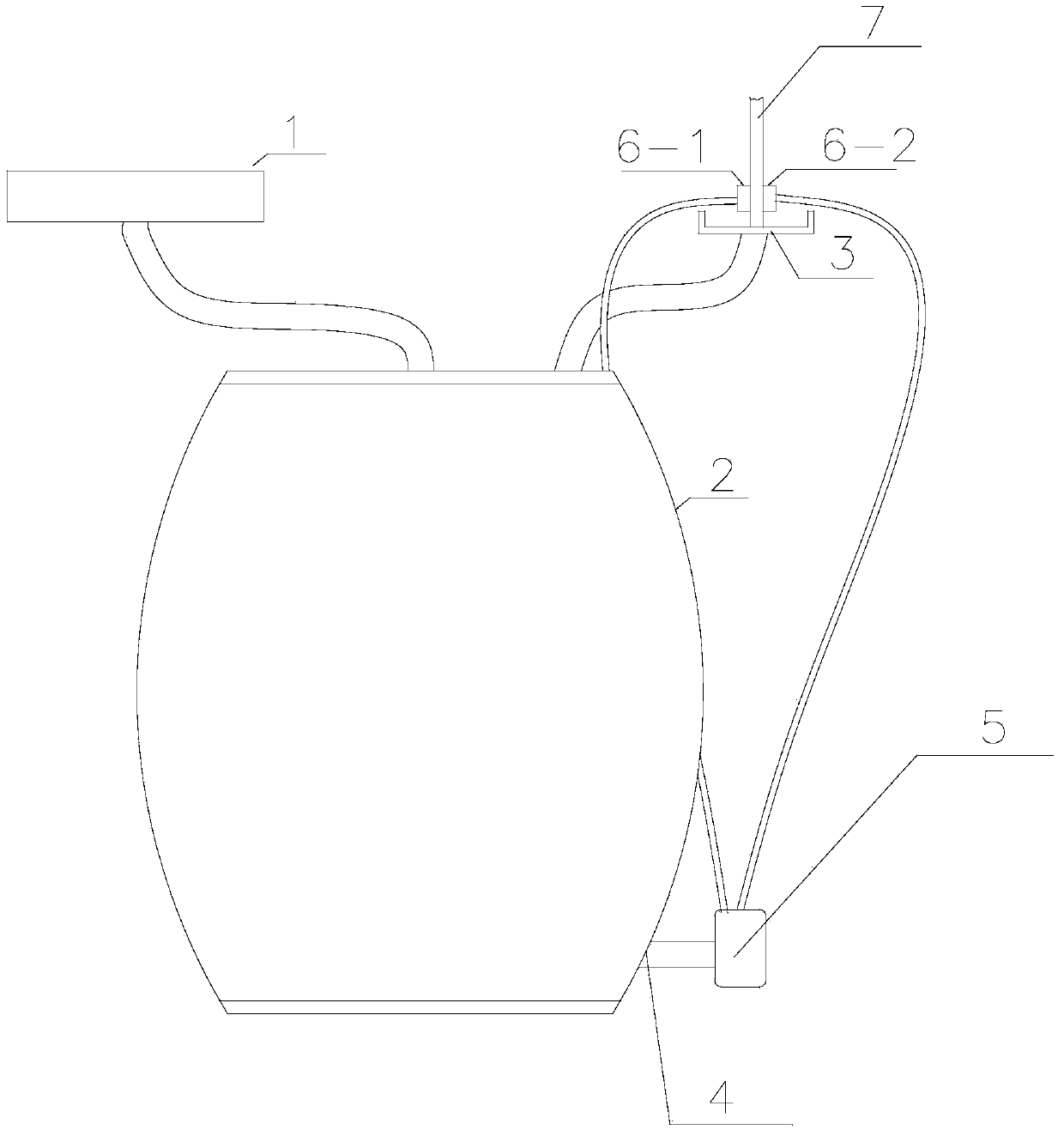

Image

Examples

Embodiment 2

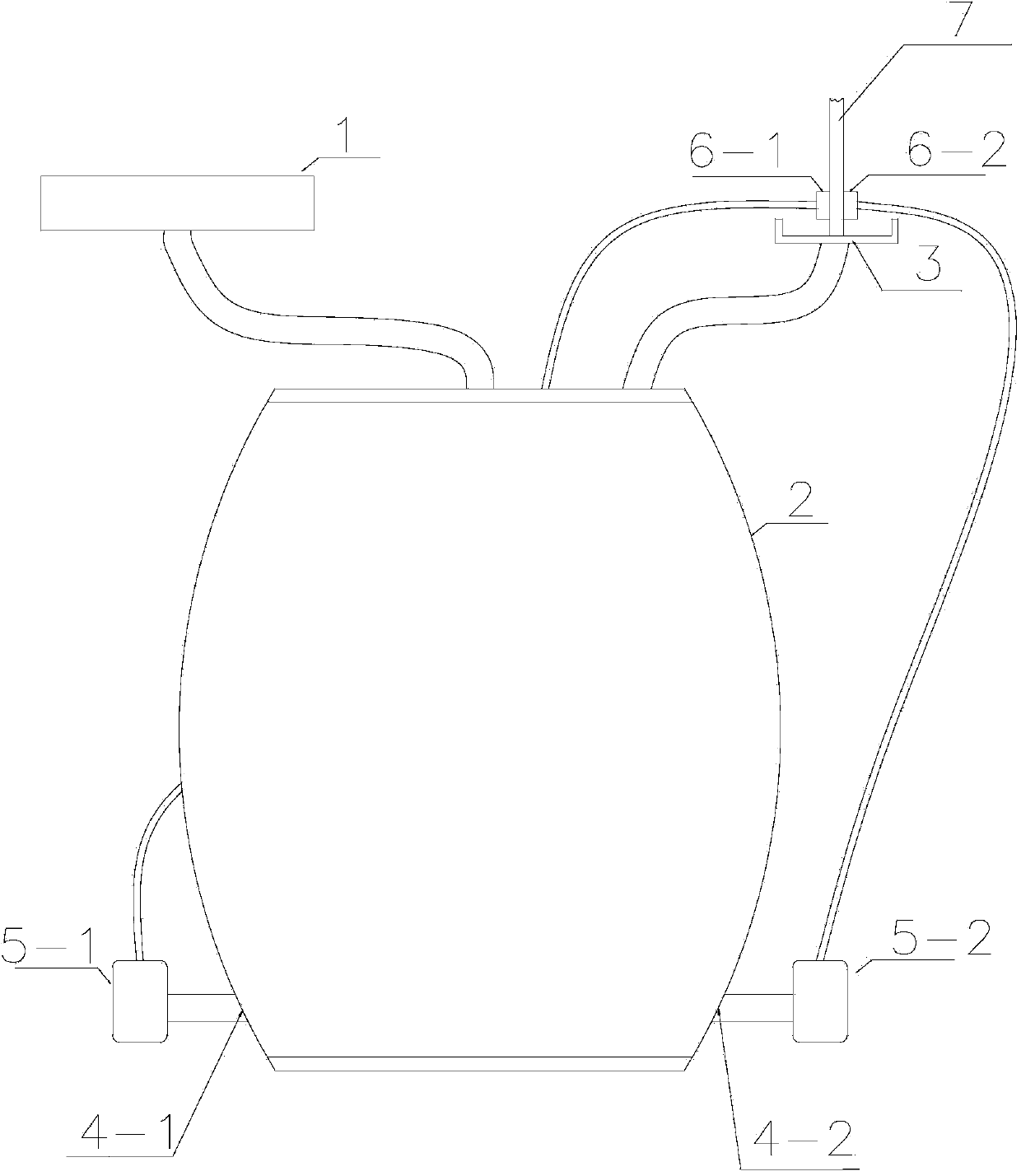

[0015] Such as figure 2 As shown, Embodiment 2: The component-wrapped liquid spraying device of the present invention includes a liquid adding device 1, a liquid container 2, a liquid spraying device and a liquid returning device 3. The liquid adding device 1 is connected to the liquid container 2 through a pipe, and the liquid receiving device The barrel 2 has a first liquid outlet 4-1 and a second liquid outlet 4-2. The liquid spray device includes a first liquid spray motor 5-1, a second liquid spray motor 5-2, and a first liquid spray brush 6 -1 and the second liquid spray brush 6-2, the first liquid outlet 4-1 is connected to the first liquid spray motor 5-1 through a pipe, and the second liquid outlet 4-2 is connected to the second liquid spray motor 5 through a pipe -2. The first liquid spray motor 5-1 is connected to the first liquid spray brush 6-1 through a pipe, the second liquid spray motor 5-2 is connected to the second liquid spray brush 6-2 through a pipe, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com