A Method for Determining the Position of Attachment Point of Full Jet Nozzle

A full-jet, point-position technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of not applying for patents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a method for determining the position of the attachment point of a full-jet nozzle. In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

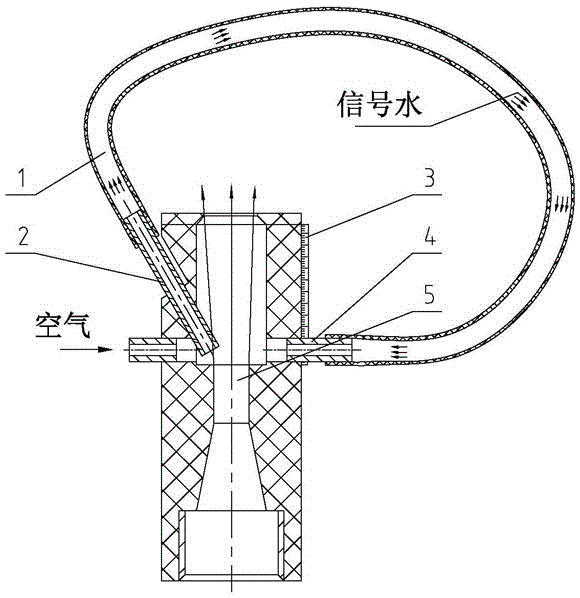

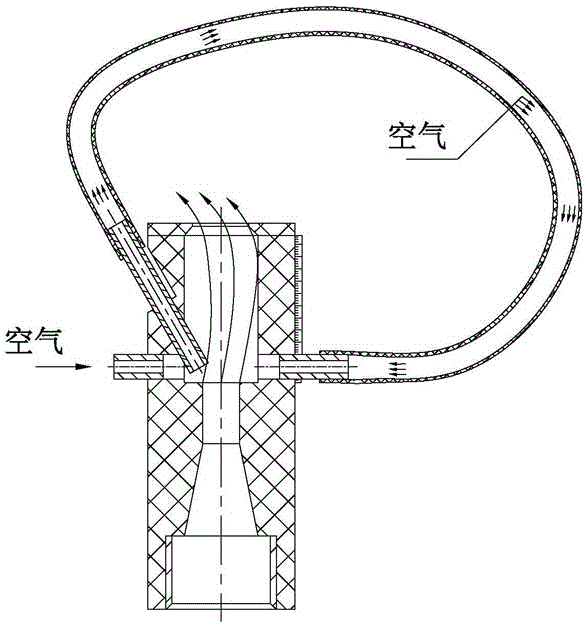

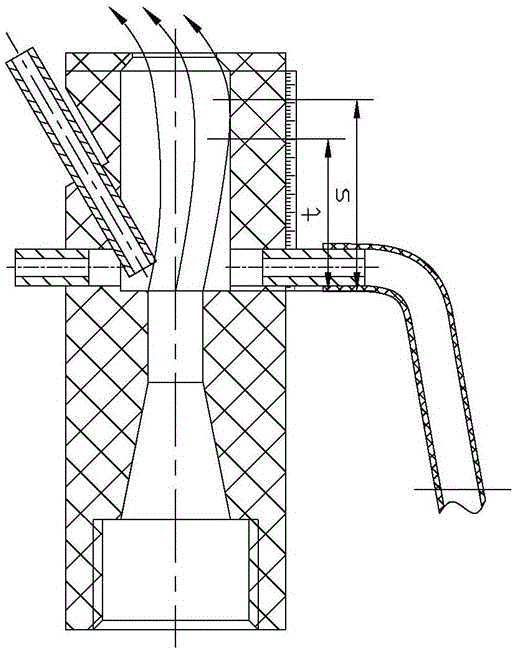

[0019] Such as figure 1 As shown, first, a transparent plexiglass 30PXH full-jet nozzle that can observe the internal flow conditions was selected as the test prototype. Before the test, a scale 3 was pasted on the outside of the 30PXH full-jet nozzle. The zero point is the exit position of the base circle hole 5 .

[0020] Next, use the conduit 1 to connect the signal nozzle 2 and the water inlet nozzle 4 of the full-jet nozzle, set the working pressure of the nozzle to 400kPa, and keep the full-jet nozzle in a stable working state. After the nozzle has been working stably for 20 minutes, start to measure and record the test data.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com