Optimization design method of fast precision casting resin prototype inner cavity sizes

A dimensional optimization, resin technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as poor shell dimensional accuracy, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] refer to Figure 2-3 . The method for optimally designing the cavity size of the rapid precision casting resin prototype of the present invention specifically includes the following steps.

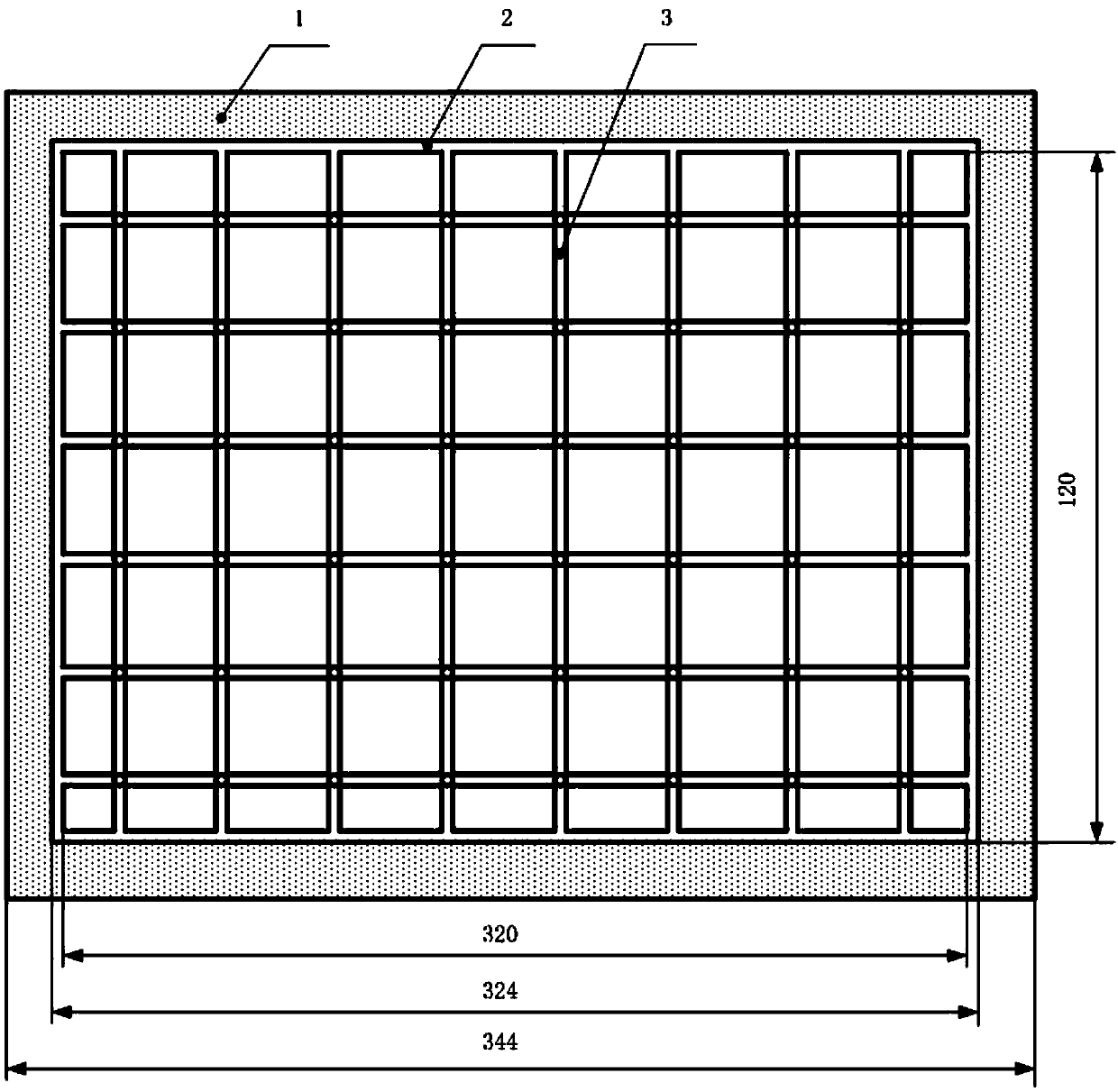

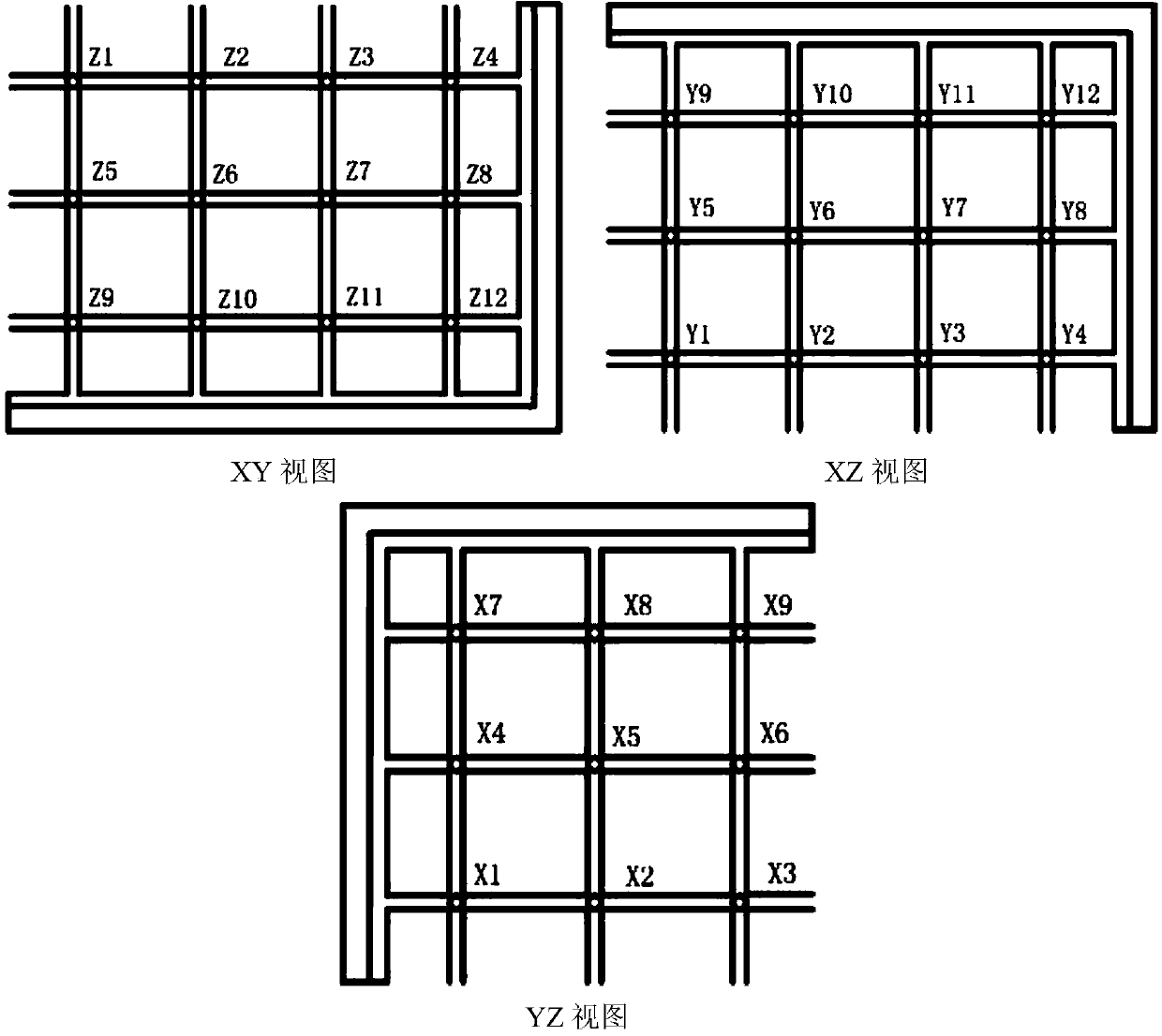

[0030] (1) Establish a geometric model. The cavity 3 of the resin prototype is the design domain, and the size of the design domain is 320mm×120mm×120mm; the mold shell 1 and the resin prototype shell 2 are the non-design domain, and the thickness of the non-design domain is 2mm; the thickness of the mold shell 1 is 10mm. Since the cuboid has symmetry, one-eighth of the cuboid is taken as the finite element model and size optimization model.

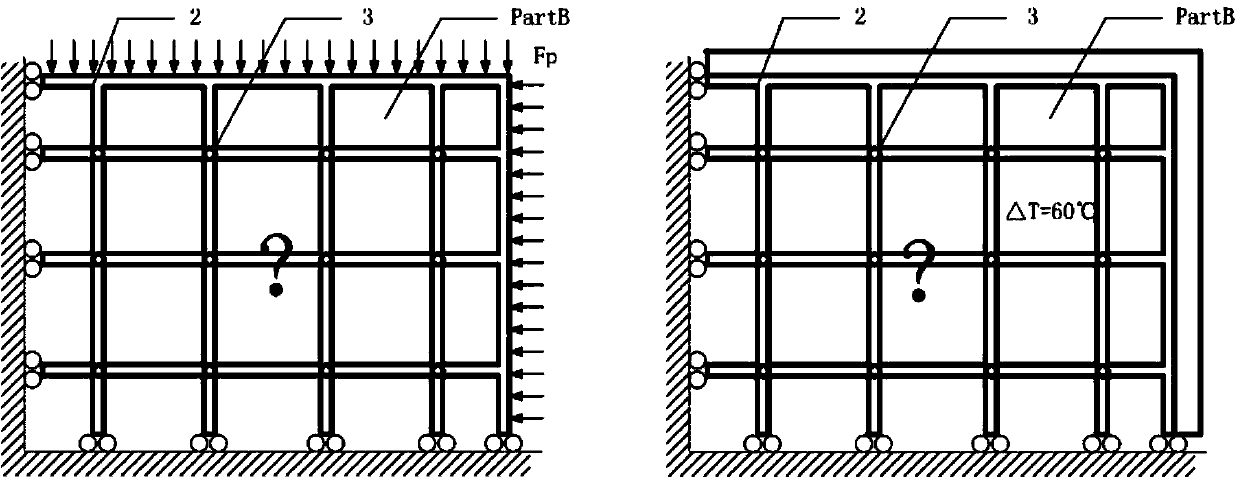

[0031] (2) Establish finite element model. The material properties of the model are shown in Table 1. The finite element model has two cases: pressure case and temperature case.

[0032] Load the temperature case. This process is a shell firing process, and the shell 1, the resin prototype shell 2 and the resin prototype inner cavity 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com