Method for overcoming welding deformation of end covers of large-size mills

A welding deformation and welding form technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve problems such as easy deformation, and achieve the effect of improving product quality, improving welding quality and reducing repair rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

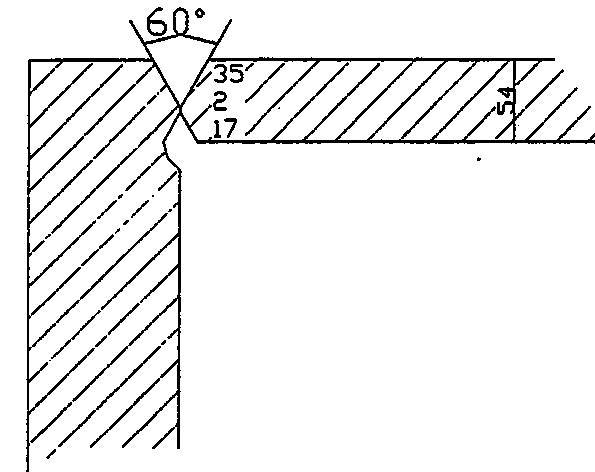

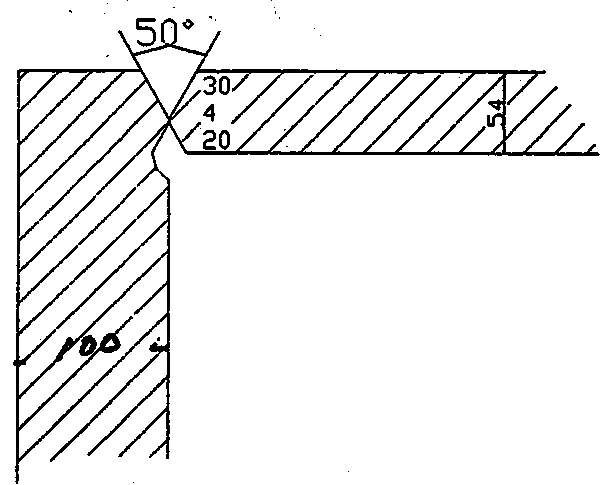

[0008] 1. Change the groove shape, change the original groove angle from 60° to 50° figure 1 figure 2 .

[0009] 2. Change the welding process.

[0010] (1). Proper preheating during welding, the preheating temperature is 50°C.

[0011] (2) . For symmetrical welding, the inner weld seam is welded first, the outer root is cleaned, and the outer weld seam is welded. Because the inner weld seam is welded first, the end cover plate is stressed in the concave direction, and has a concave tendency. The outer root is cleaned, and after the outer weld is welded, a convex force that offsets the concave force can be generated, and the deformation of the end cover can be controlled.

[0012] 3. Weld the end cover plate with the adjacent small barrel section to form small parts, and then check the deformation. If the deformation is greater than 3mm, it can be corrected by 800T hydraulic machine or flame.

[0013] 21 mills welded by this method do not need to use 800T hydraulic pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com