A fully automatic yarn binding machine

A fully automatic, woolen yarn technology, which is applied in special decorative structures, decorative arts, and conveying filamentous materials, etc., can solve the problems of high cost, slow speed, and low yield of yarn balls, etc., to improve production efficiency and reduce Production cost and labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

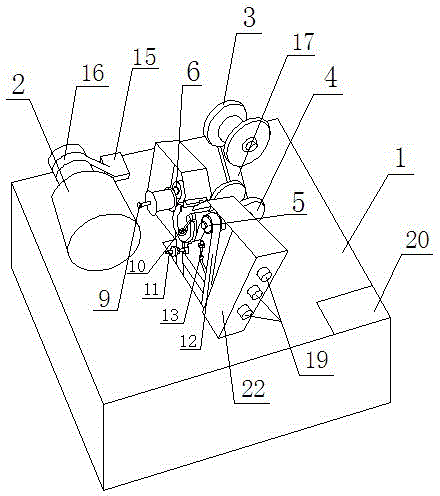

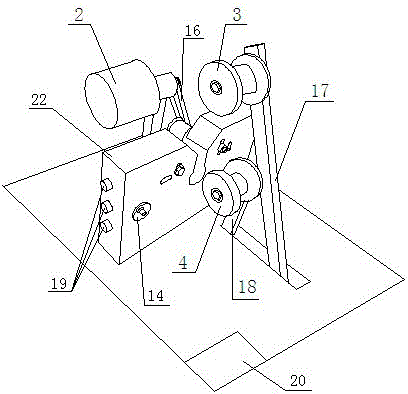

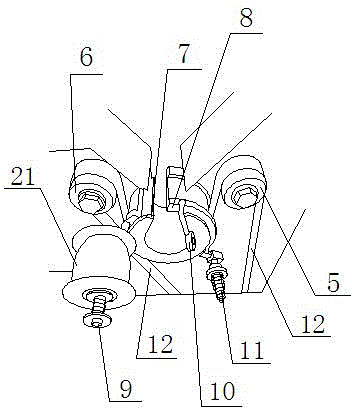

[0019] The specific embodiment of the present invention is described below in conjunction with accompanying drawing: a kind of full-automatic yarn bundle ball machine, as Figure 1-Figure 3 As shown, it includes a frame 1, a power roll 2, a winding roll a3, a winding roll b4, and a wire binding device. The frame is provided with a control system and a power device, and the control system receives setting commands from the operation panel 20. For the operation of the motor in the frame, the upper surface of the frame is provided with a protective cover 22, and one side of the protective cover 22 is provided with a power roller 2 driven by a stepping motor, and the other side is provided with a winding roller a3 supported by an adjustable column a17 and Winding roller b4 from column b, adjustable column a17 can rotate around a fulcrum in a small range, and this fulcrum is set in frame 1; The position on the top and the position of the winding roller b4 on the column b18 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com