Polymer cement waterproof paint

A waterproof coating and polymer technology, which is applied in the field of waterproof coatings and polymer cement waterproof coatings, can solve the problems of poor performance of waterproof coatings and high elongation of coating films, and achieve the effects of preventing water penetration, high elongation, and good elasticity

Active Publication Date: 2013-12-18

XIAMEN LIKASAM WATERPROOF ENG

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to overcome the poor performance of existing waterproof coatings, and provide a polymer cement waterproof coating, which has

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

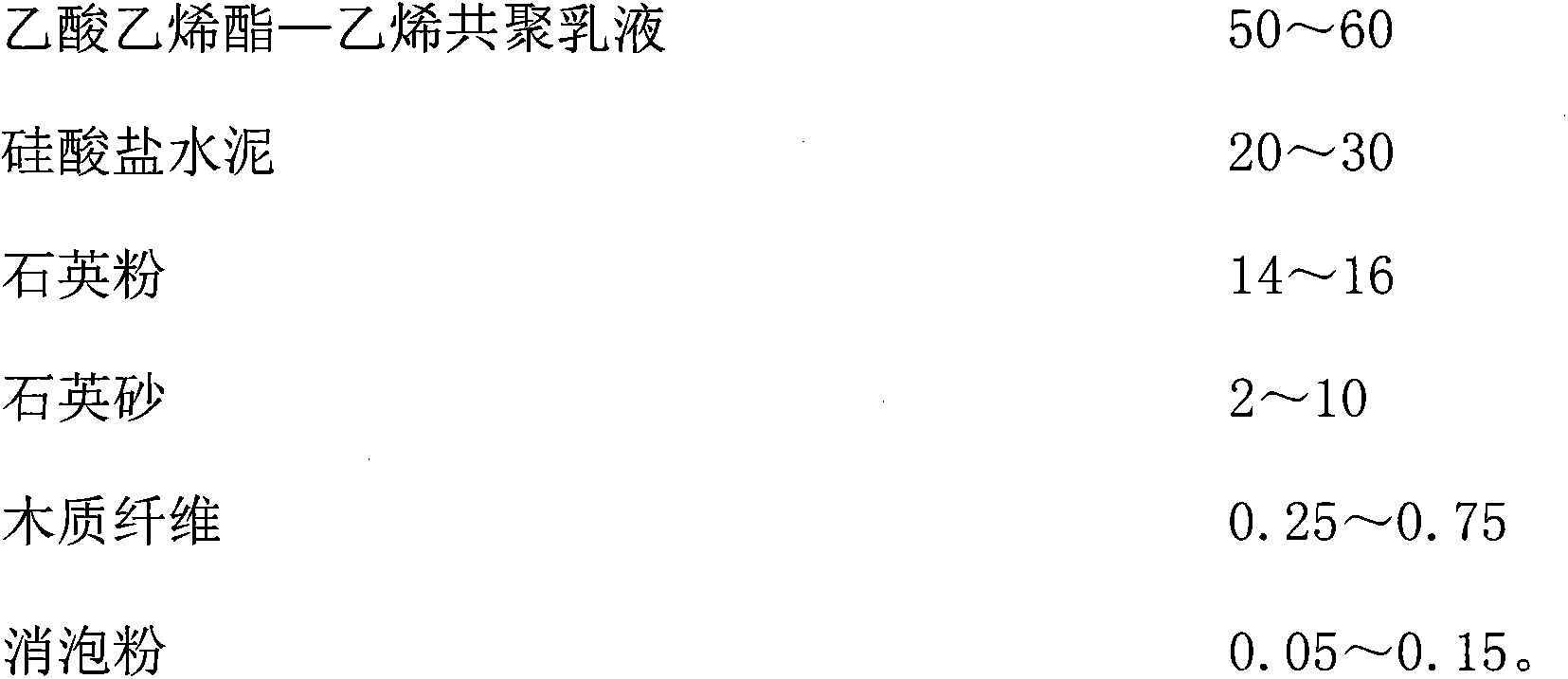

[0020] Example 1

[0021] The polymer cement waterproof coating described in this embodiment is composed of the following components in weight ratio:

[0022]

Example Embodiment

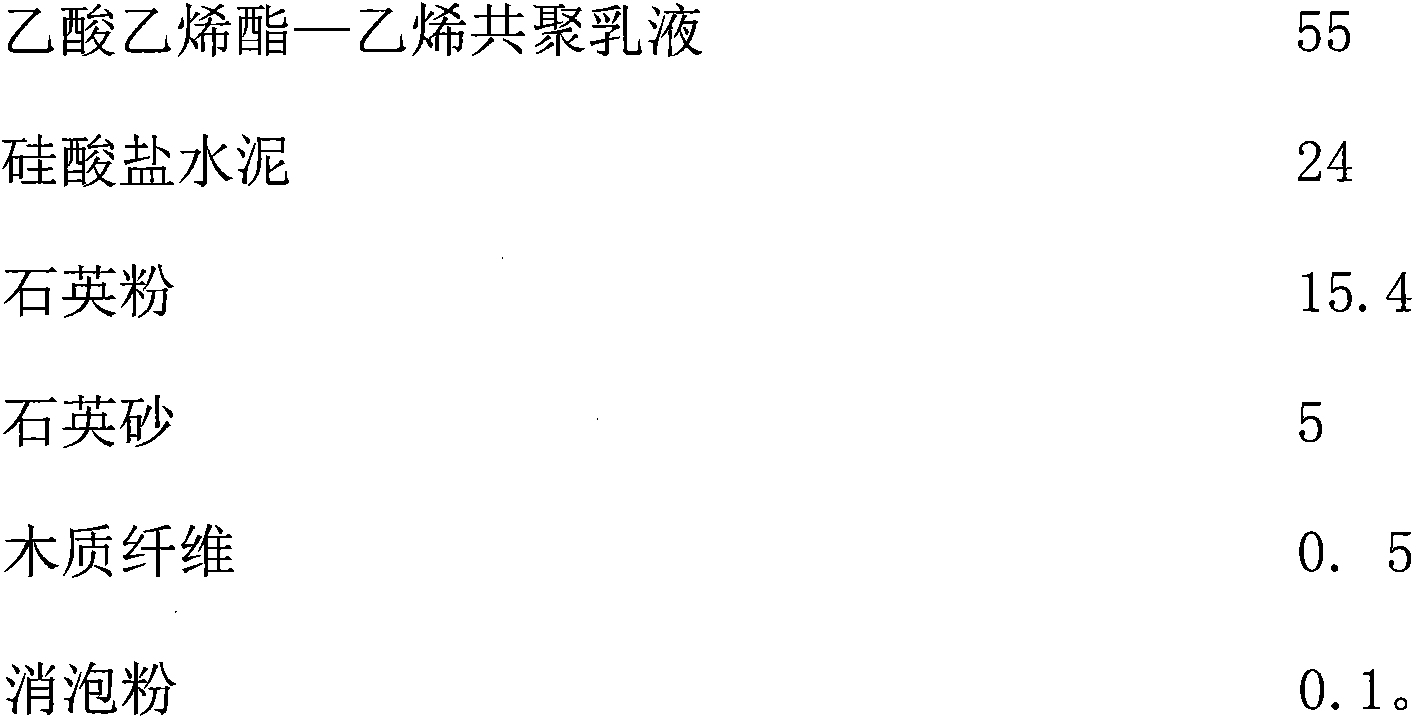

[0023] Example 2

[0024] The polymer cement waterproof coating described in this embodiment is composed of the following components in weight ratio:

[0025]

Example Embodiment

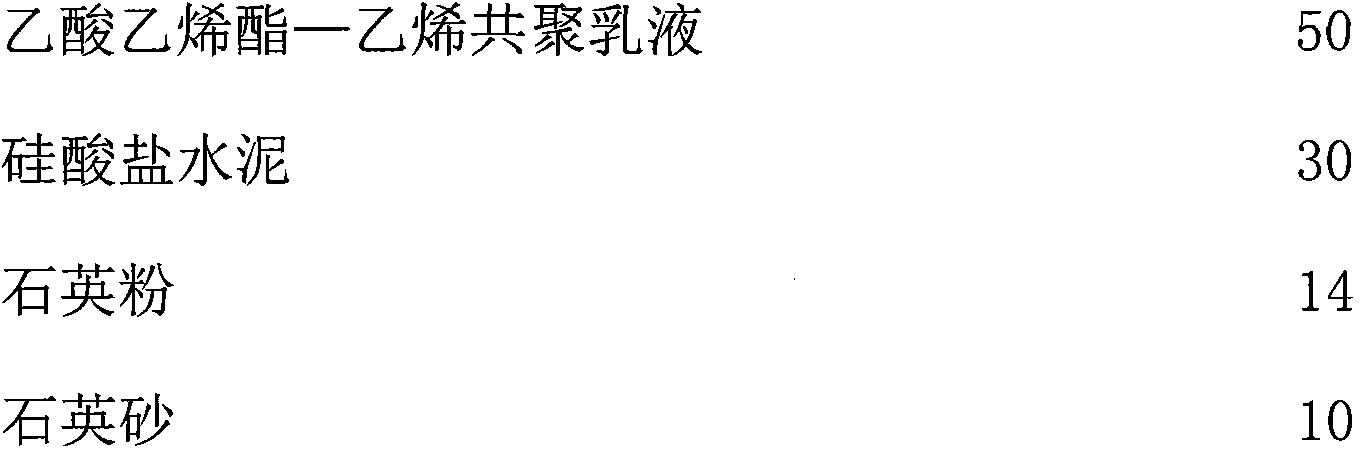

[0026] Example 3

[0027] The polymer cement waterproof coating described in this embodiment is composed of the following components in weight ratio:

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Login to view more

Abstract

The invention discloses polymer cement waterproof paint which consists of the following components in percent by weight: 50-60% of a vinyl acetate-ethylene copolymer emulsion, 20-30% of silicate cement, 14-16% of quartz powder, 2-10% of quartz sand, 0.25-0.75% of wood fiber and 0.05-0.15% of defoaming powder. The polymer cement waterproof paint disclosed by the invention is cement-based waterproof paint which takes the high molecular ethylene copolymer emulsion as a main film forming matter and various fillers such as cement as the main components. Slurry and powder are mixed to react chemically to form a tough elastic waterproof membrane. The membrane has good adhesion to concrete and mortar and can be compactly and firmly combined with concrete and mortar permanently so as to prevent water permeation. The paint has excellent initial adhesion and mechanical stability, higher viscosity and consistence, high coating ductility and good elasticity, and can be used for construction on moist basic levels.

Description

technical field [0001] The invention relates to a waterproof coating, in particular to a polymer cement waterproof coating, which belongs to the technical field of building materials. Background technique [0002] It is necessary to form a film on the surface of the building through the volatilization of solvent or water or the chemical reaction of the two components, so as to isolate the surface of the building from water, so as to play the role of waterproof and sealing. These viscous liquids for painting Called waterproof coating. In some military projects, mechanical pits, tunnels, swimming pools, pools, basements, water supply pipe drainage and irrigation sluices pasted with tiles, and concrete structures such as roofs, toilets, balconies, and pipe joints, although they are coated with conventional waterproof coatings, Once cracks appear in the concrete, water seepage still occurs in the cracks. The reason is that the existing common waterproof coatings have poor initi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C04B28/04C04B111/27

Inventor 刘绍贵

Owner XIAMEN LIKASAM WATERPROOF ENG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap