Device for separating and recycling tail gas generated in polypropylene production

A recovery device and polypropylene technology, applied in the purification/separation of hydrocarbons, hydrogen separation, separation methods, etc., can solve problems such as environmental pollution, unrecoverable propylene monomer, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

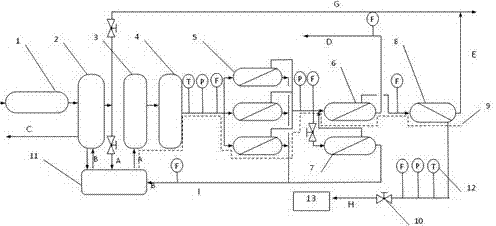

[0014] The device is mainly composed of gas cabinet (1), compression condensation system (2), precision bag filter (3), microporous membrane filter (4), three-stage four-stage membrane separation system (5, 6, 7, 8) , steam or electric heat tracing system (9), control and regulating valve group (10), heat exchanger and monitoring instrument system (12), connected in the following way.

[0015] (1) The outlet of the exhaust gas cabinet (1) is connected to the inlet of the compression condensing system (2).

[0016] (2) The non-condensable gas outlet of the compression condensation system (2) is connected to the inlet of the heat exchanger (11), and the outlet of the heat exchanger (11) A is connected to the inlet of the precision bag filter (3).

[0017] (3) The outlet of the precision bag filter (3) is connected to the inlet of the microporous filter (4), and the outlet of the microporous filter (4) is connected to the inlet of the first-stage one-stage propylene enrichment me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com