construction machinery

A technology of construction machinery and racks, which is applied in the direction of mechanical equipment, earth movers/excavators, fluid pressure actuation devices, etc., can solve the problems of large space occupation and high cost, save resources, improve environmental protection performance, improve Effect of Bridge-to-Charge Ratio Distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

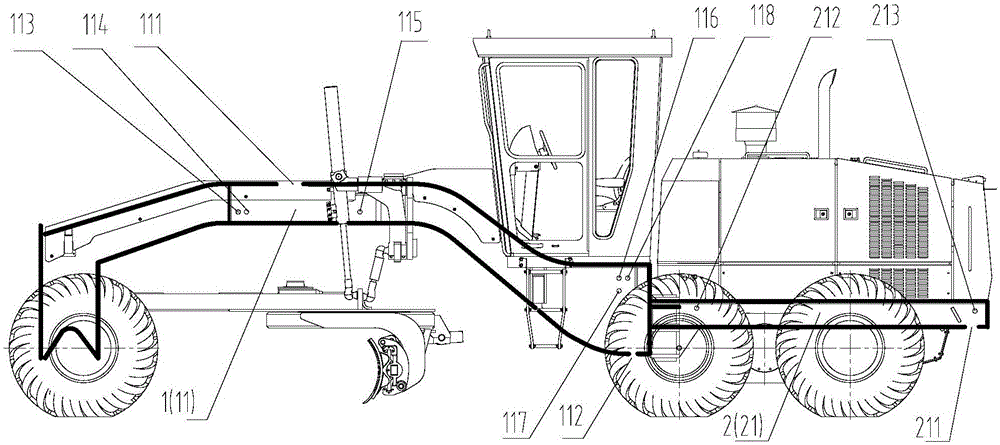

[0018] The basic idea of the present invention is: in order to solve the problems of high cost and large occupied space caused by the arrangement of existing liquid tanks (such as fuel tanks, hydraulic oil tanks and / or water tanks, etc.), the present invention proposes a construction machine, the construction machine The inside of the frame is a cavity structure, and the frame is isolated and closed to form at least one closed section for storing liquids (such as fuel, hydraulic oil or coolant), without the need to separately design liquid tanks (fuel tanks and hydraulic oil tanks) or water tank, etc.) to make the layout of the whole machine more compact and reasonable, and the use of existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com