Electroluminescence device and manufacturing method thereof

An electroluminescent device and an organic light-emitting layer technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems such as poor contact, achieve the effects of shortening film forming time, improving product yield, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

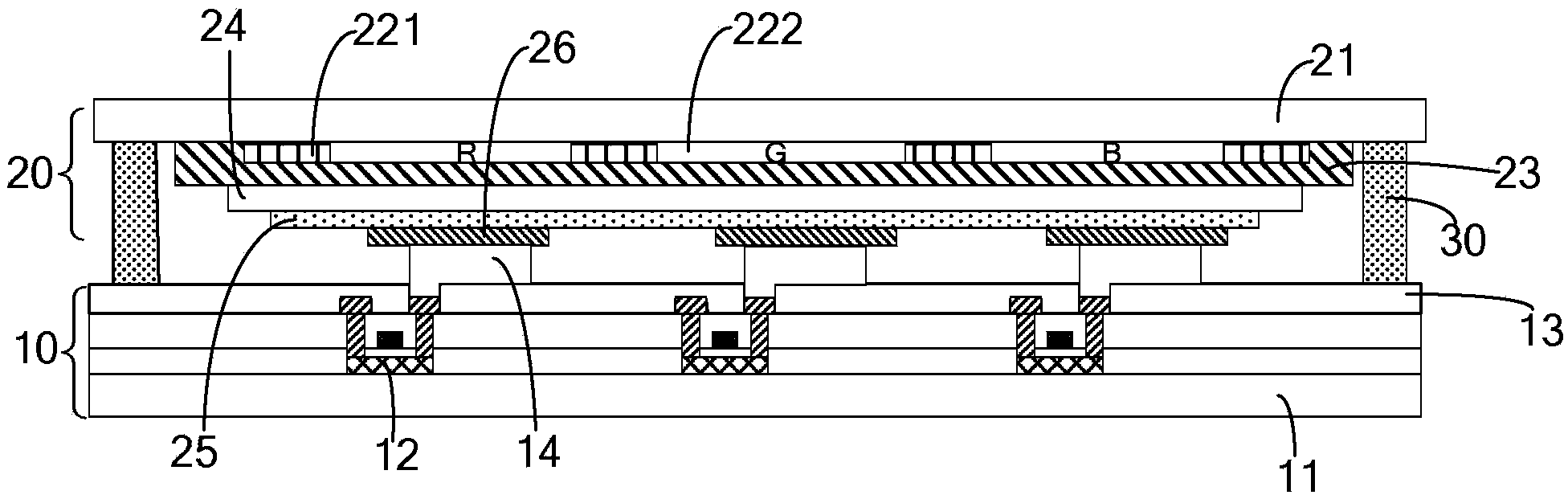

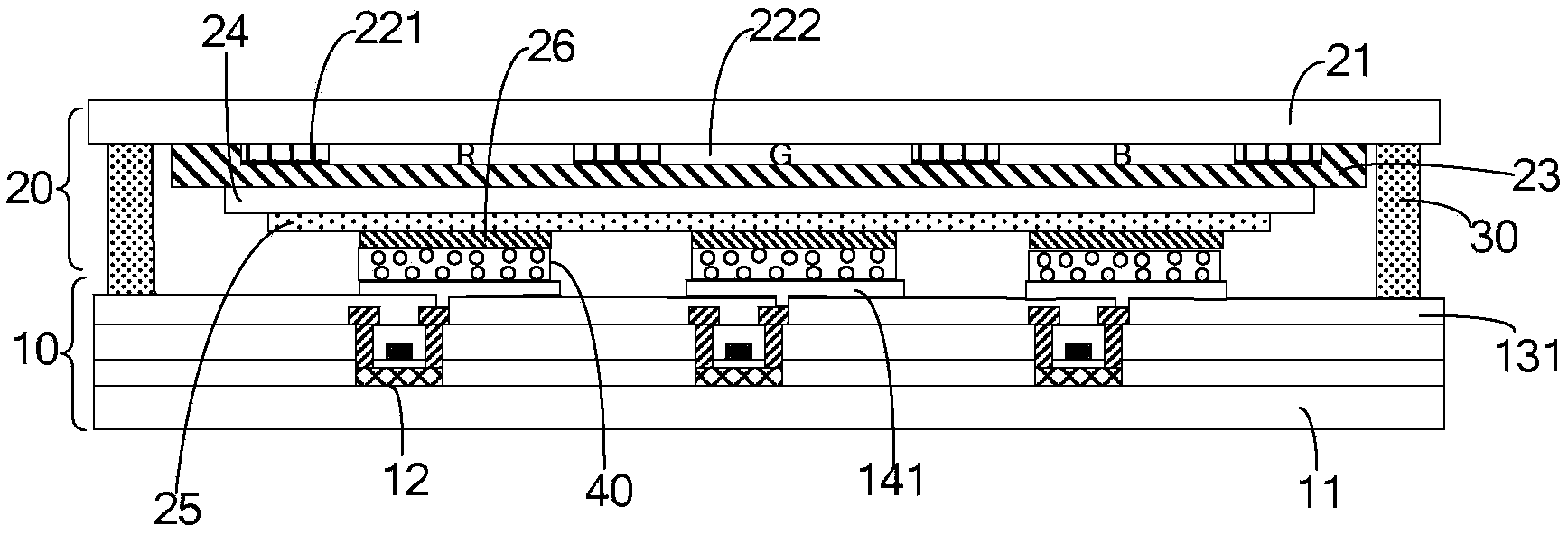

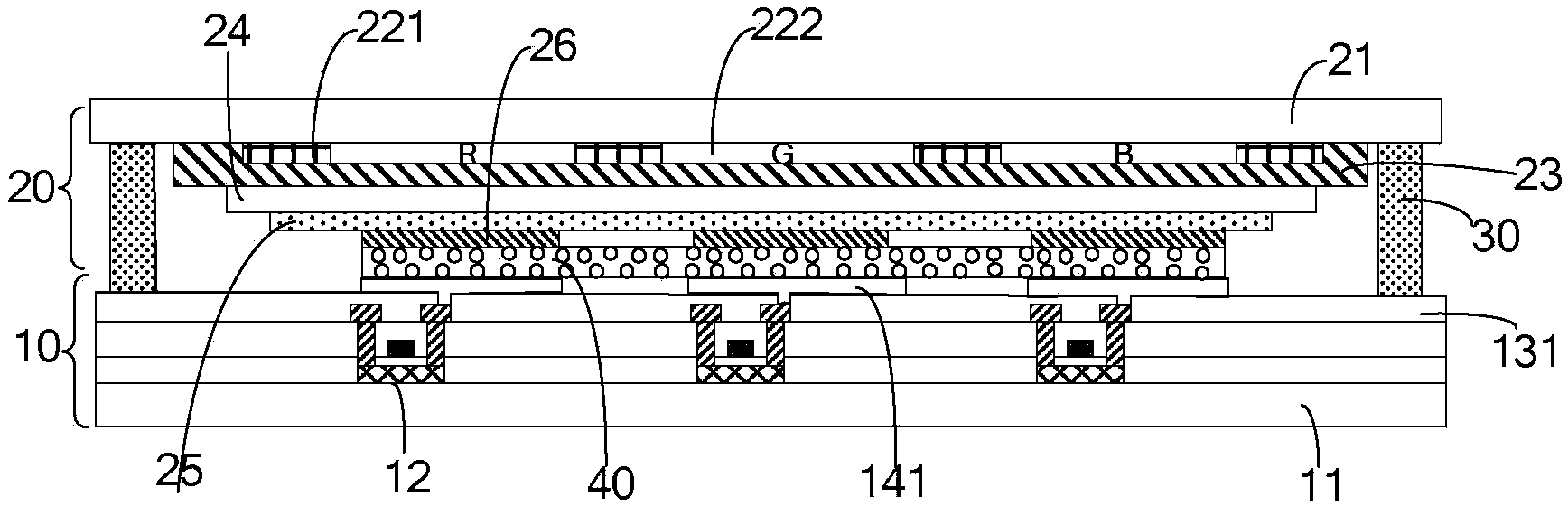

[0046] The embodiment of the present invention provides an electroluminescent device, refer to figure 2 As shown, the device includes: an array substrate 10 and a color filter substrate 20. The array substrate 10 includes: a first substrate 11, a thin film transistor 12, a first protective layer 131, and a drain connected to the thin film transistor that are sequentially disposed on the first substrate 11 The color filter substrate 20 includes: a second substrate 21, a color filter layer, a flat layer 23, a first electrode 24, an organic light-emitting layer 25, and a second electrode sequentially disposed on the second substrate 21 26. The color filter layer includes: a black matrix 221 (BM), a color resist block 222 separated by a black matrix 221 (red, green, and blue R / G / B in the figure); the second electrode 26 is connected to the first The electrodes 141 are connected together by conductive glue 40.

[0047] Generally speaking, the active electroluminescence device include...

Embodiment 2

[0062] On the other hand, this embodiment also provides a manufacturing method of an electroluminescent device, which includes: a color filter substrate manufacturing process, an array substrate manufacturing process, a color filter substrate and an array substrate aligning process, where, as Picture 10 As shown, the box-matching process of the color filter substrate and the array substrate includes:

[0063] Step 101: Apply conductive glue on the box facing surface of the color filter substrate and / or the box facing surface of the array substrate;

[0064] Step 102: align the color filter substrate with the array substrate, and heat and press the conductive adhesive during the encapsulation process, so that the second electrode and the first connecting electrode are connected together by the conductive adhesive .

[0065] Wherein, in step 101, conductive glue can be applied only to the top surface of the second electrode and / or the top surface of the first connecting electrode on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com