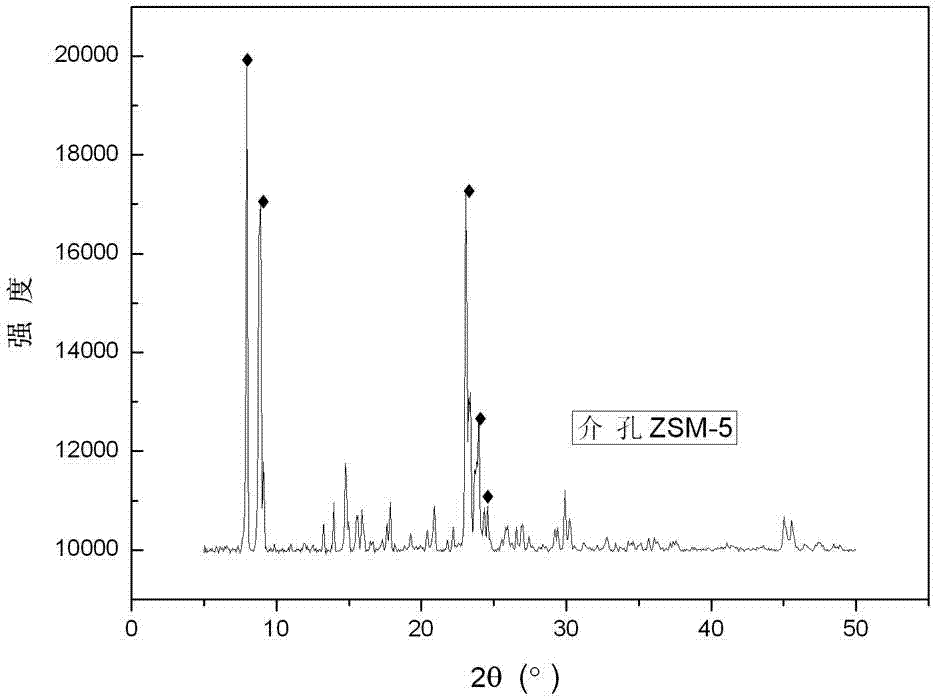

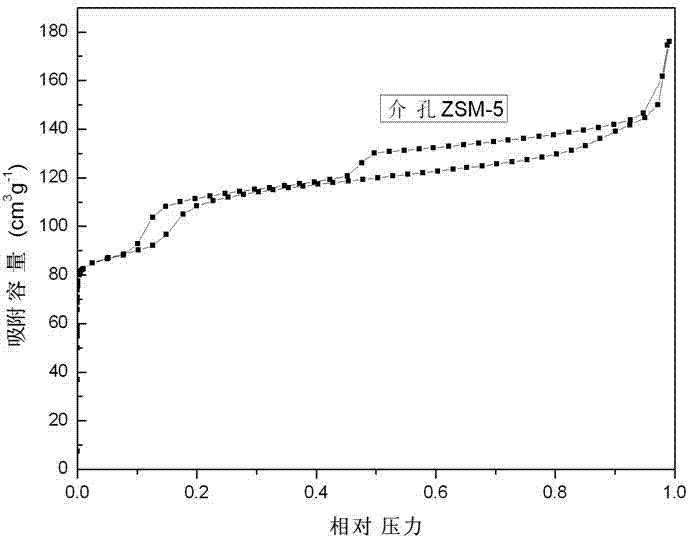

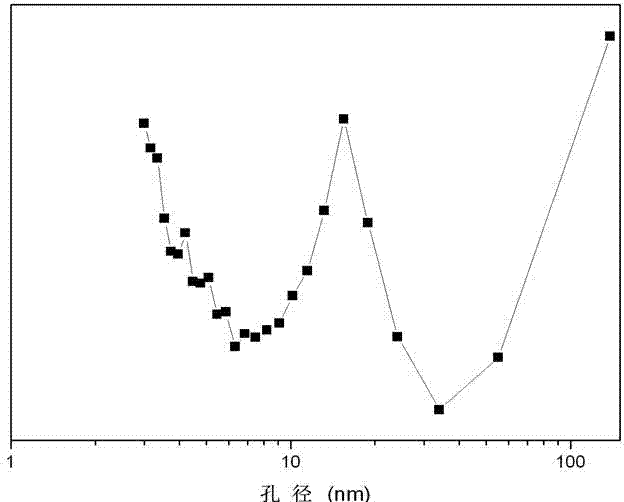

Molecular sieve catalyst containing mesoporous ZSM-5 and preparation method and application of molecular sieve catalyst

A technology of ZSM-5 and molecular sieve, which is applied to molecular sieve catalysts, chemical instruments and methods, and the production of hydrocarbons from oxygen-containing organic compounds, etc., can solve problems such as unfavorable industrial production and damage to the micropore structure of catalysts, and achieve broad industrialization prospects. Agglomeration-promoting and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] MZ5-1 catalyst is prepared as follows:

[0034] a) Take sodium silicate as the silicon source and tetrapropylammonium bromide as the templating agent, mix them with a certain proportion of deionized water, and heat them ultrasonically until they are dissolved. The ultrasonic temperature is 35°C to obtain liquid a. As the aluminum source and potassium fluoride as potassium salt, dissolve in a certain proportion of deionized water, stir and dissolve at room temperature to form liquid b, and slowly drop liquid b into liquid a under the action of ultrasound to obtain a mixed system. The molar ratio of each component in the mixed system is: , SiO 2 :Al 2 o 3 : Templating agent: KF: H 2 O = 1:0.0025:0.3:0.1:30;

[0035] b) Ultrasonic dissolution is carried out when the mixture is heated to 40°C, the ultrasonic frequency is 40KHZ, the ultrasonic power is 100W,

[0036] After ultrasonication for 10 minutes, transfer to mechanical stirring, control the ambient temperature a...

Embodiment 2

[0044] MZ5-2 catalyst is prepared as follows:

[0045] The ultrasonic time in Example 1 was extended to 20min, and the rest of the synthesis steps were the same as in Example 1.

[0046] Put 0.5g, 40~60mesh MZ5-2 catalyst into a quartz reaction tube with a diameter of 9mm, the raw material is 20~50%wt methanol water, and the mass space velocity (relative to pure methanol) is 4.0 h -1 , the reaction temperature is 300~500°C.

Embodiment 3

[0048] MZ5-3 catalyst is prepared as follows:

[0049] The ultrasonic time in Example 1 was extended to 30min, and the rest of the synthesis steps were the same as in Example 1.

[0050] Put 0.5g, 40~60mesh MZ5-3 catalyst into a quartz reaction tube with a diameter of 9mm, the raw material is 20~50%wt methanol water, and the mass space velocity (relative to pure methanol) is 4.0 h -1 , the reaction temperature is 300~500°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap