Method for producing water-resistant aluminum nitride

A manufacturing method and technology of aluminum nitride, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of reduced thermal conductivity on the surface of aluminum nitride powder, and achieve the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

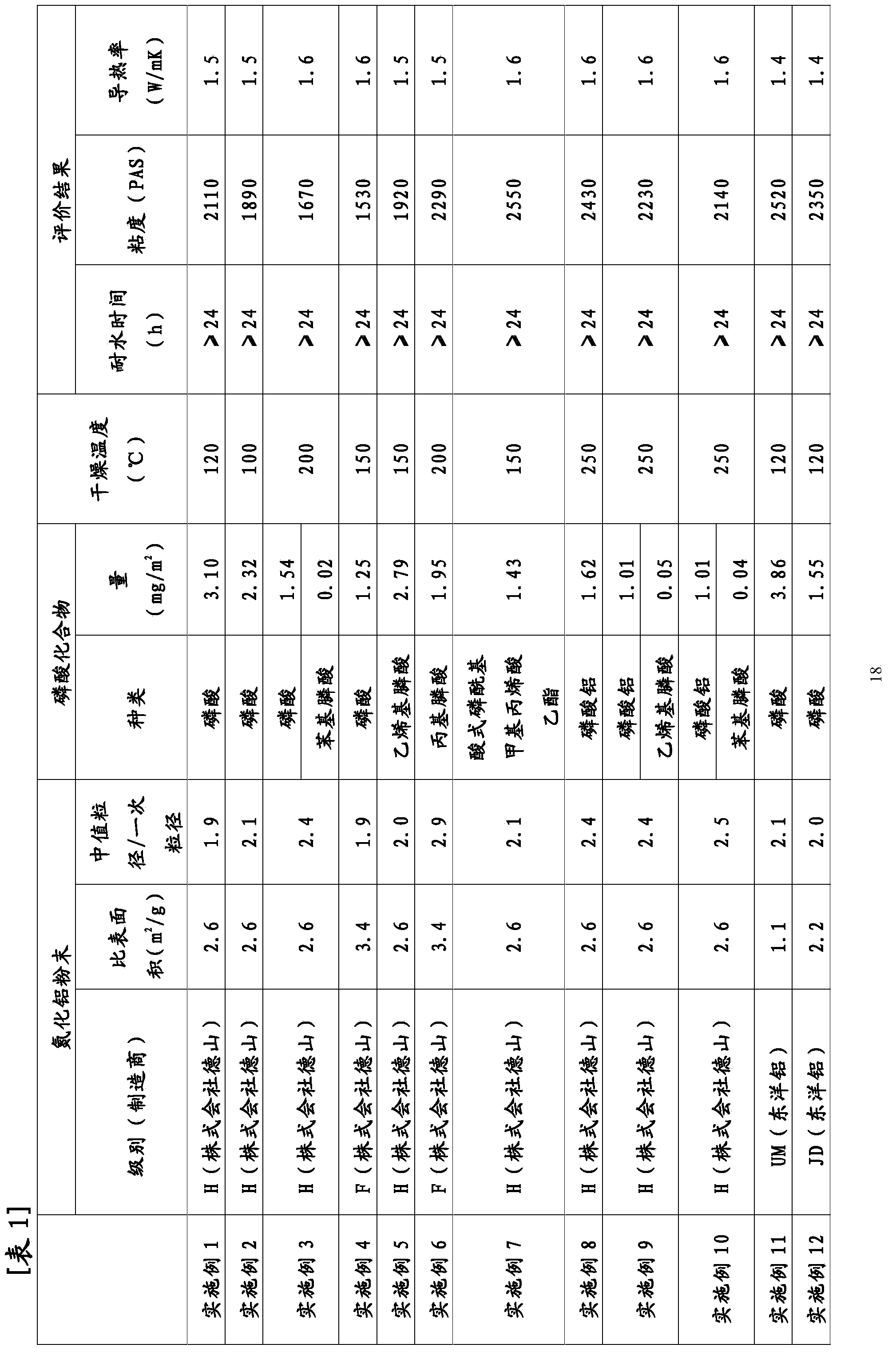

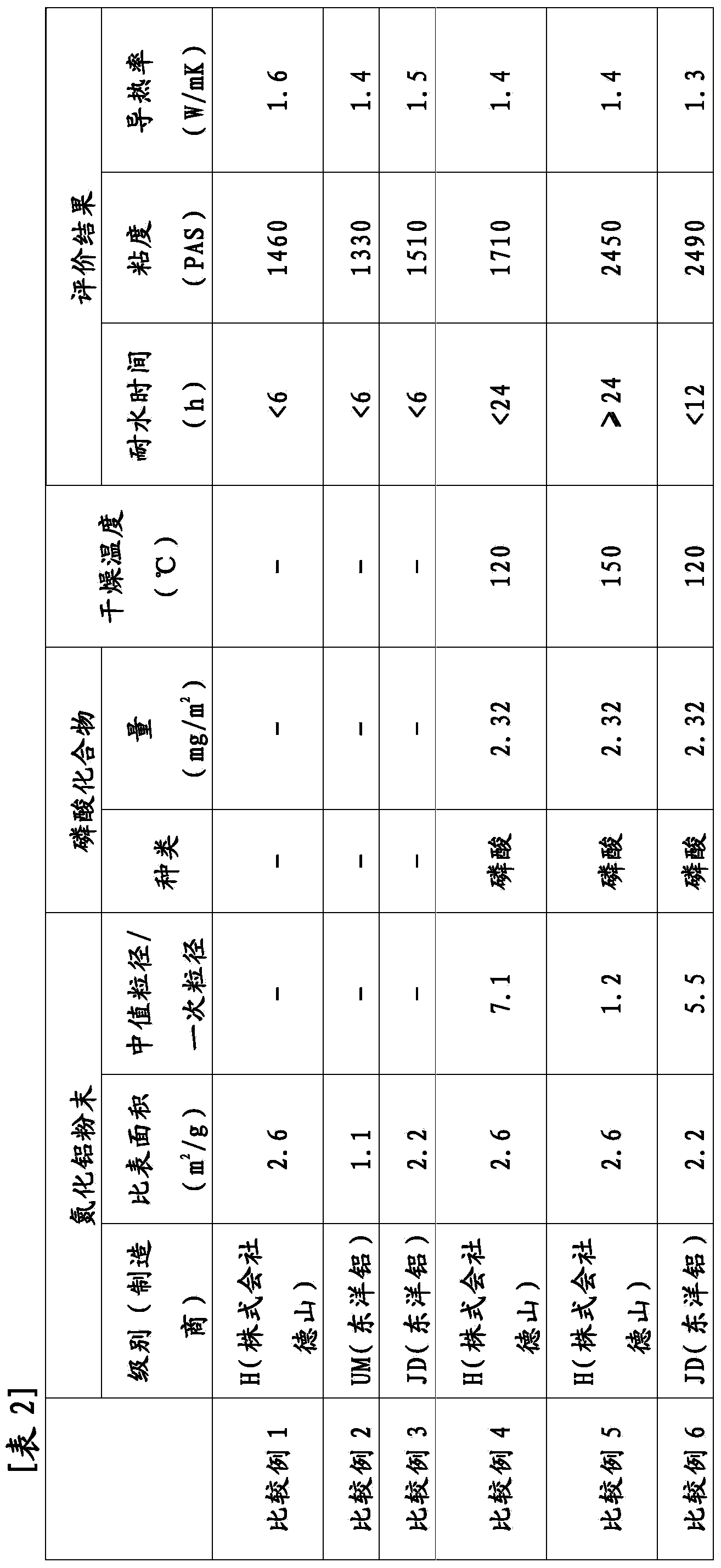

[0098] Aluminum nitride powder (H grade, BET specific surface area 2.6m 2 / g, produced by Tokuyama Co., Ltd.) 1kg, phosphoric acid (H 3 PO 4 , special grade, purity 85wt%, manufactured by Wako Pure Chemical Industries Co., Ltd.) 9.4 g and 1.5 kg of water were mixed in a mortar, and dispersed under a pressure of 100 MPA using a Nanomizer (NMS-200L, manufactured by Nanomizer Co., Ltd.). mix. Next, the dispersed mixture was dried at an inlet temperature of 200°C using a spray dryer (R-100, manufactured by Purisu Co., Ltd.), and then dried in an oven at 120°C for 15 hours to obtain water-resistant AlN powder.

[0099] Table 1 shows the water resistance of the obtained aluminum nitride powder, and the viscosity and thermal conductivity of the composite material produced using the aluminum nitride powder.

Embodiment 2

[0101] Aluminum nitride powder (H grade, BET specific surface area 2.6m 2 / g, produced by Tokuyama Co., Ltd.) 1kg, phosphoric acid (special grade, purity 85wt%, manufactured by Wako Pure Chemical Industries Co., Ltd.) 7.1g and ethanol 1.5kg were dispersed and mixed, and dried at 100°C for 15 hours to obtain Water resistant aluminum nitride powder.

[0102] Table 1 shows the water resistance of the obtained aluminum nitride powder, and the viscosity and thermal conductivity of the composite material produced using the aluminum nitride powder.

Embodiment 3

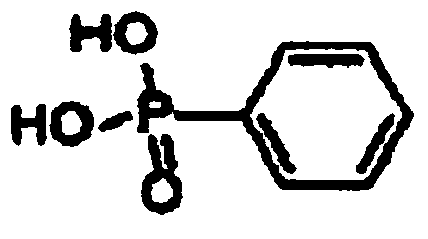

[0104] Aluminum nitride powder (H grade, BET specific surface area 2.6m 2 / g, produced by Tokuyama Co., Ltd.) 1kg, phosphoric acid (special grade, purity 85wt%, manufactured by Wako Pure Chemical Industries, Ltd.) 4.7g, phenylphosphonic acid (manufactured by Wako Pure Chemical Industries, Ltd.) 0.1g and isopropyl After dispersing and mixing 1.5 kg of alcohol, it was dried at 200° C. for 15 hours to obtain a water-resistant aluminum nitride powder.

[0105] Table 1 shows the water resistance of the obtained aluminum nitride powder, and the viscosity and thermal conductivity of the composite material produced using the aluminum nitride powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com