Toner and process for producing same

A technology of toner and colorant, which is applied in the field of toner and its manufacture, can solve problems such as reduction, fragility and durability of toner, and achieve the effects of improved miscibility and good heat offset resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

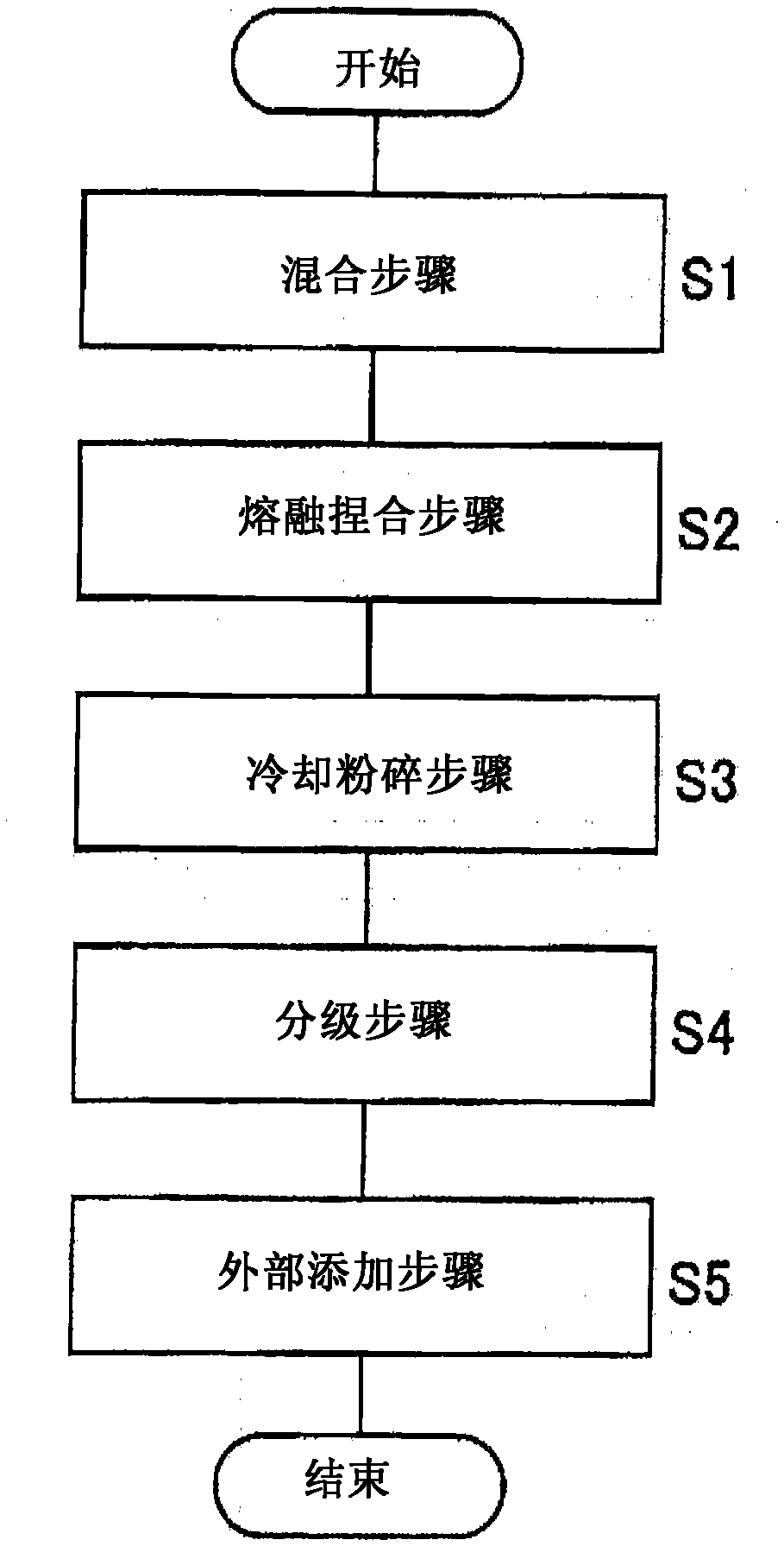

Method used

Image

Examples

preparation example Construction

[0050] In the preparation of the polyester resin A, as raw materials, an aromatic dicarboxylic acid and a rosin are used as an acid component, and a trivalent or higher alcohol is used as a polyhydric alcohol. Aromatic dicarboxylic acids and higher than trihydric alcohols are reacted to form moderately branched polyol structures.

[0051] When the polyester resin contains a moderately branched structure, the low-temperature fixability of the toner can be maintained without extremely increasing the softening temperature of the resin, and the molecular weight distribution of the resin can be expanded. Therefore, it is possible to obtain a resin having a wide distribution on the high molecular weight side, and thus improve the offset resistance of the toner.

[0052] Examples of aromatic dicarboxylic acids as acid components used in the preparation of polyester resin A include phthalic acid, terephthalic acid, isophthalic acid, biphenyl dicarboxylic acid, naphthalene dicarboxylic...

Embodiment

[0139] Hereinafter, the present invention will be described in detail with reference to examples and comparative examples.

[0140] The physical properties of Examples and Comparative Examples were measured as described below.

[0141] Glass transition temperature (Tg) of polyester resin

[0142] Using a differential scanning calorimeter (trade name: Diamond DSC, available from PerkinElmer Co., Ltd.), according to Japanese Industrial Standard (JIS) K7121-1987, at 10°C per minute (10 0.01 g sample is heated to measure the DSC curve at a heating rate of ℃ / min).The straight line obtained by extending the baseline of the low temperature side of the endothermic peak corresponding to the glass transition to the high temperature side in the obtained DSC curve is the same as that obtained at the opposite The temperature at the intersection between the tangent lines drawn at the point of the maximum gradient of the curve on the low temperature side of the endothermic peak was determin...

preparation example 1

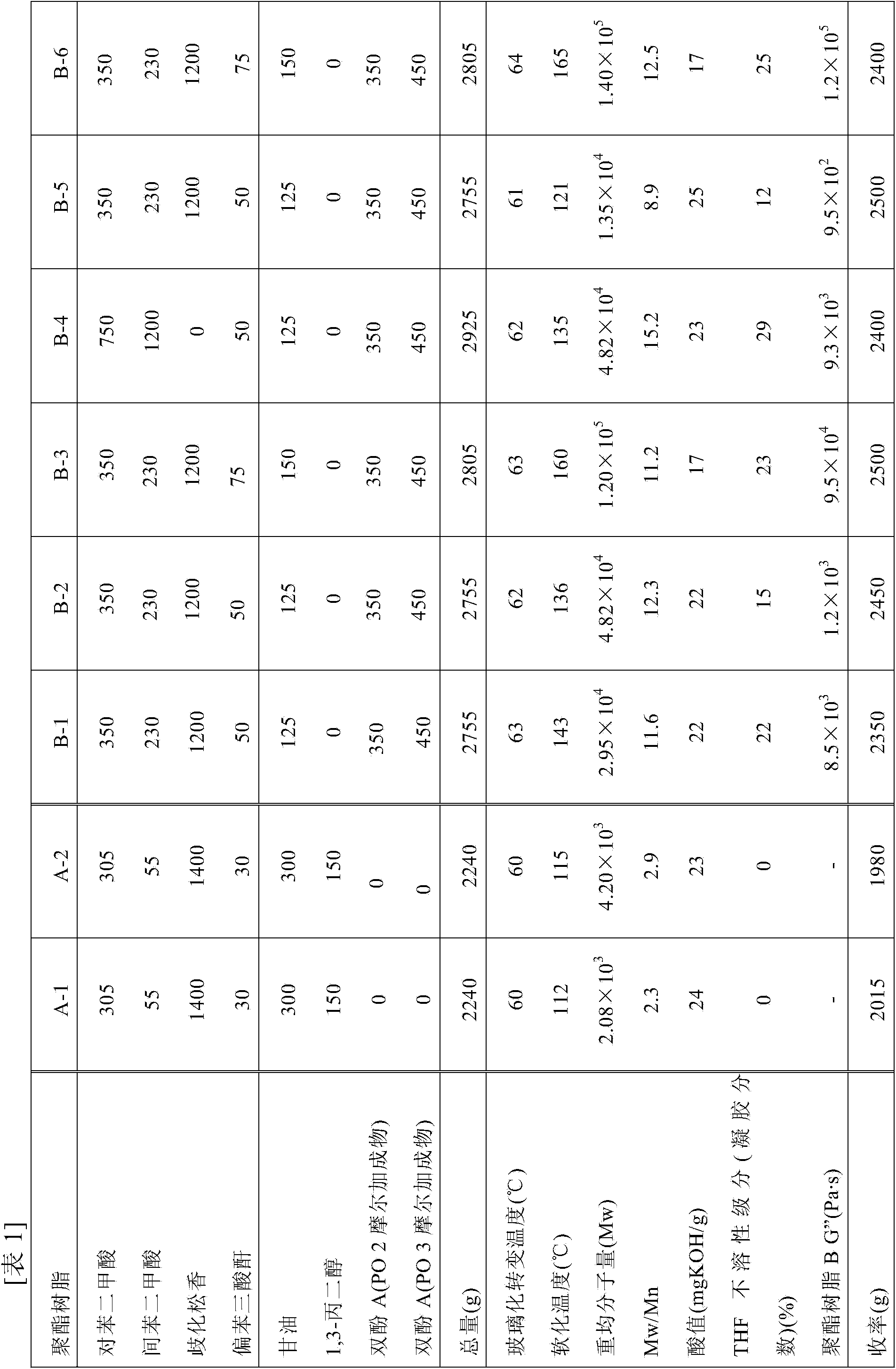

[0161] Preparation of polyester resin A-1

[0162] 305 g of terephthalic acid, 55 g of isophthalic acid, 30 g of trimellitic anhydride, and 1400 g of disproportionated rosin ( Acid value: 157.2mgKOH / g); 300g glycerol and 150g1,3-propanediol as the alcohol component; 1.79g tetra-n-butyl titanate (relative to the total amount of the acid component and the alcohol component 100 parts by weight, equivalent to at 0.080 parts by weight). These materials were stirred under a nitrogen atmosphere to perform a polycondensation reaction at 250° C. for 10 hours while distilling off generated water. When it is confirmed with a flow tester that the predetermined softening temperature is reached, the reaction is stopped. Thus, 2015 g (yield: 90%) of polyester resin A-1 (glass transition temperature: 60° C., softening temperature: 112° C., weight average molecular weight: 2800, Mw / Mn: 2.3, acid value: 24 mgKOH / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com