The Method of Improving the Surface Hardness of Chinese Fir Board

A technology of surface hardness and fir board, which is applied in the field of wood processing, can solve the problems of delamination and peeling of painted boards, easy delamination of painted paint, and small surface adhesion of fir boards, so as to achieve increased surface hardness and added value. And the effect of improving economic benefits and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

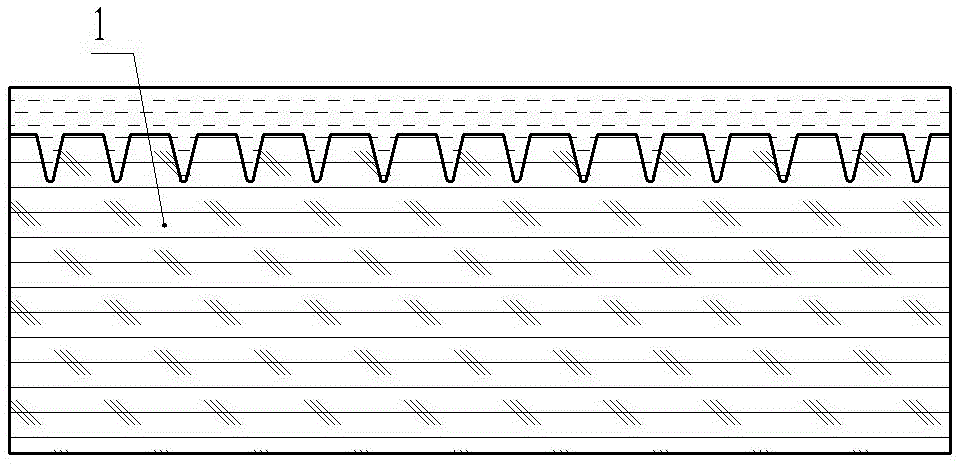

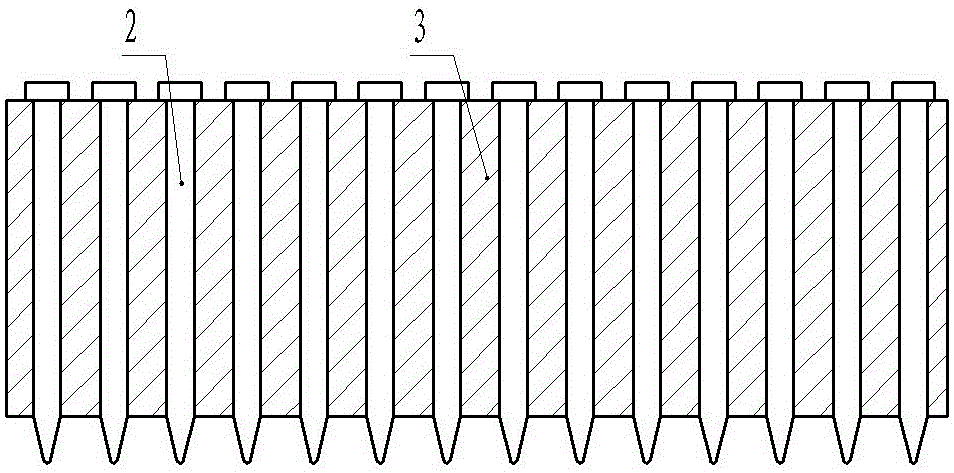

[0017] The method for improving the surface hardness of fir boards is to cook, dry and process fir boards into fir boards 1, which includes the following steps:

[0018] A. The wood stamping machine includes needle dies, such as figure 2 The needle pressing die shown has a pressing plate 3 and a plurality of extruding needles 2 distributed on the pressing plate 3, and the diameter of the needle head of the extruding needle 2 located on the lower surface of the pressing plate 3 is 1 mm and the length is 1 mm. The surface of the Chinese fir board 1 is extruded and needle-punched using a needle die, so that the surface of the Chinese fir board 1 is distributed with a plurality of upper, lower, and small conical pinholes, and the number of pinholes is 7000 per square meter. The diameter of each pinhole on the surface of the Chinese fir board is 1 mm, and the depth of the pinhole is 1 mm; The surface is set vertically; the paint coated on the surface of the fir board is closely c...

Embodiment 2

[0024] The method for improving the surface hardness of fir boards is to cook, dry and process fir boards into fir boards 1, which includes the following steps:

[0025] A, plank punching machine comprises needle press die, and needle press die has pressing plate 3 and a plurality of extruding pins 2 that are distributed on pressing plate 3, and the diameter of extruding pin 2 being positioned at the pinhead of pressing plate 3 lower surface is 3 millimeters, and length is 3mm. use as figure 2 The needle press mold shown squeezes and needles the surface of the Chinese fir board 1, so that a plurality of upper, lower, and small conical pinholes are distributed on the surface of the Chinese fir board 1, and the number of pinholes is 8500 per square The diameter of each pinhole on the surface of the Chinese fir board is 3 millimeters, and the depth of the pinhole is 3 millimeters; the needle press mold of the present embodiment is extruded to the surface of the Chinese fir boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com