Bucket elevator with adjustable tension

A bucket elevator, tension technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problem of slippage of the return belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

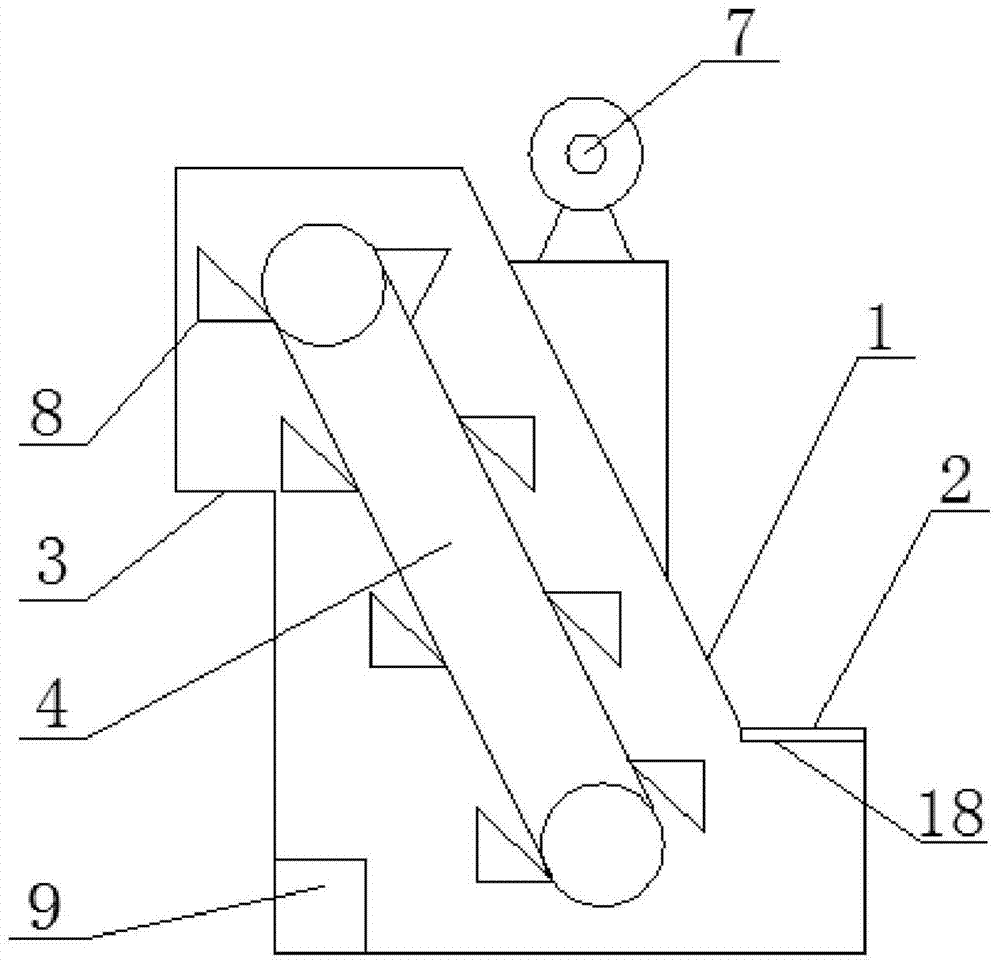

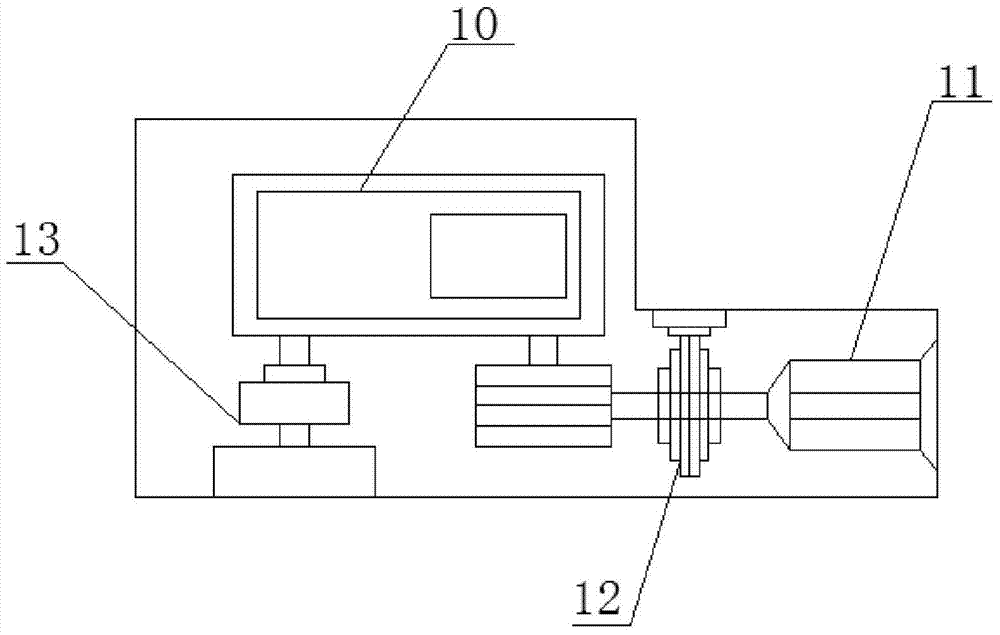

[0021] like figure 1 , figure 2 and Figure 4 A bucket elevator with adjustable tension is shown, its structure includes a casing 1, a hopper 8, a conveying device 4 and a driving device 7, and the casing 1 is respectively provided with an inlet 2 and an outlet 3, and the hopper 8 is placed on the conveying device 4, the driving device 7 is connected with the conveying device 4, the filter screen 18 is arranged on the feeding port 2, and the tensioning device 9 is arranged in the casing 1, and the tensioning device 9 is connected with the conveying device 4. The drive device 7 is composed of a motor 11 , a reducer 10 and a shaft coupling 13 connected in sequence, and the motor 11 is fixed on the casing 1 . The conveying device 4 includes an upper roller, a lower roller and a rubber belt connecting the upper and lower rollers, the hopper 8 is placed on the rubber belt, the upper roller is connected with the coupling 13, the lower roller is connected with the screw 5, and the...

Embodiment approach 2

[0023] like figure 1 , figure 2 and Figure 4 A bucket elevator with adjustable tension is shown, its structure includes a casing 1, a hopper 8, a conveying device 4 and a driving device 7, and the casing 1 is respectively provided with an inlet 2 and an outlet 3, and the hopper 8 is placed on the conveying device 4, the driving device 7 is connected with the conveying device 4, the filter screen 18 is arranged on the feeding port 2, and the tensioning device 9 is arranged in the casing 1, and the tensioning device 9 is connected with the conveying device 4. The conveying device 4 includes an upper sprocket, a lower sprocket and a sleeve roller chain connecting the upper and lower sprockets, the hopper 8 is placed on the sleeve roller chain, the upper sprocket is connected with the shaft coupling 13, and the lower sprocket The sprocket is connected with the screw rod 5, the screw rod 5 passes through the U-shaped groove on the support plate 19 and is fixed on the support pl...

Embodiment approach 3

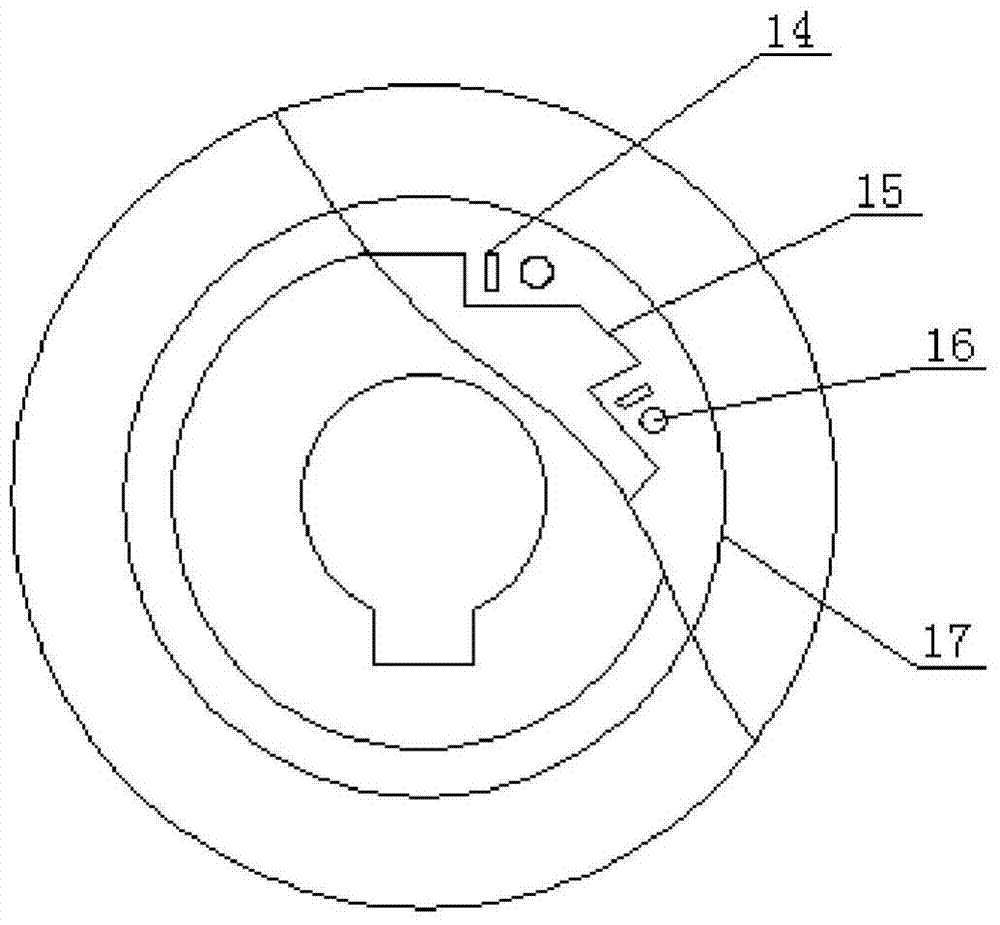

[0025] like figure 1 , figure 2 and Figure 5 A bucket elevator with adjustable tension is shown, its structure includes a casing 1, a hopper 8, a conveying device 4 and a driving device 7, and the casing 1 is respectively provided with an inlet 2 and an outlet 3, and the hopper 8 is placed on the conveying device 4, the driving device 7 is connected with the conveying device 4, the filter screen 18 is arranged on the feeding port 2, and the tensioning device 9 is arranged in the casing 1, and the tensioning device 9 is connected with the conveying device 4. The conveying device 4 includes an upper roller, a lower roller and a rubber belt connecting the upper and lower rollers, the hopper 8 is placed on the rubber belt, the upper roller is connected with the shaft coupling 13, and the lower roller is connected with the support plate 19 through a bearing 22, The support plate 19 is connected with the lever 21, and the lever 21 is connected with the weight 20 through the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com