Grinding equipment

A technology for grinding and grinding tools, which is used in abrasive surface adjustment devices, metal processing equipment, grinding machine parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

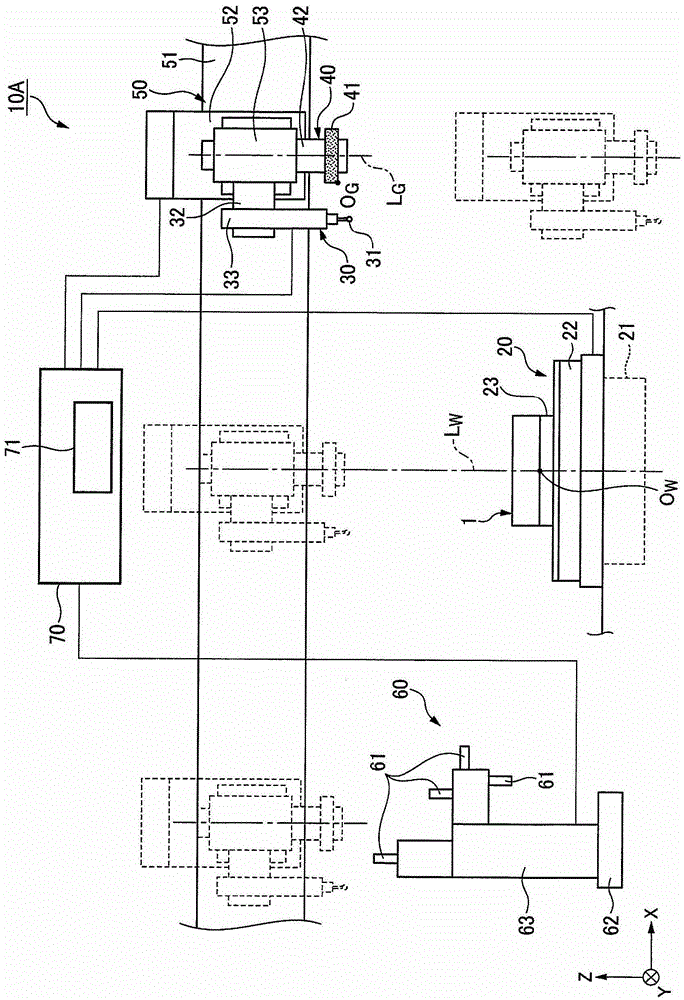

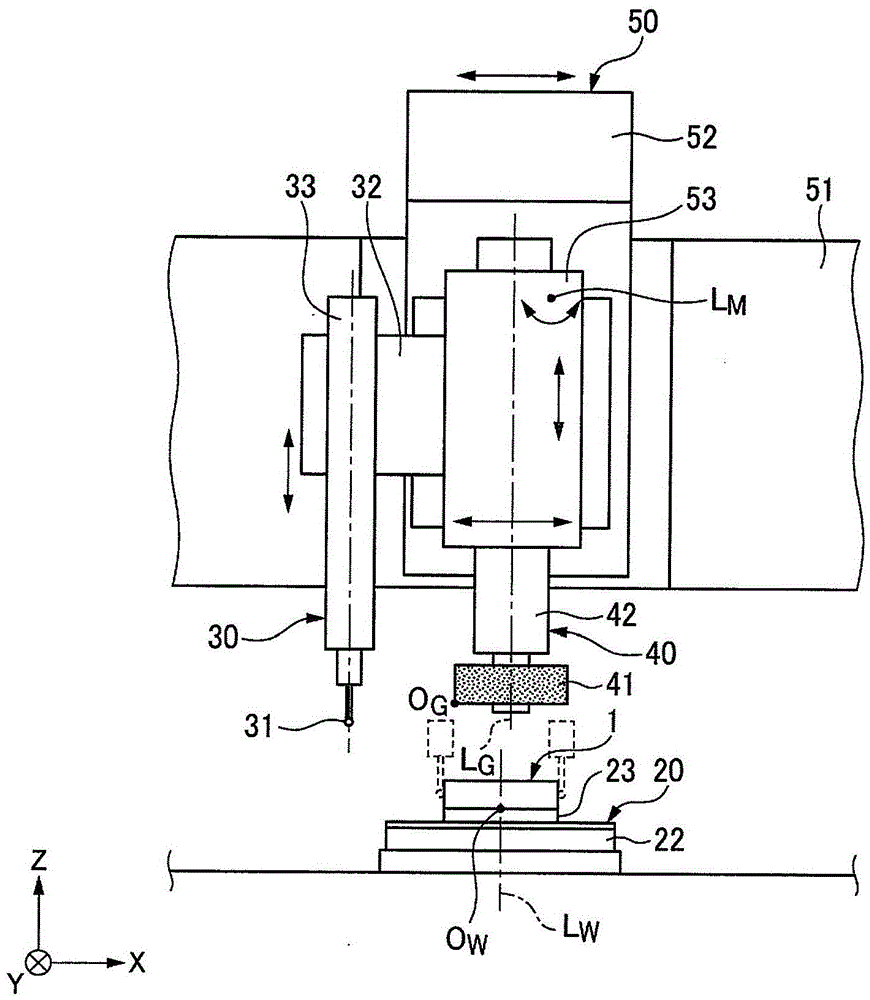

[0043] First, refer to Figure 1 to Figure 7 , the first embodiment of the grinding machine of the present invention will be described.

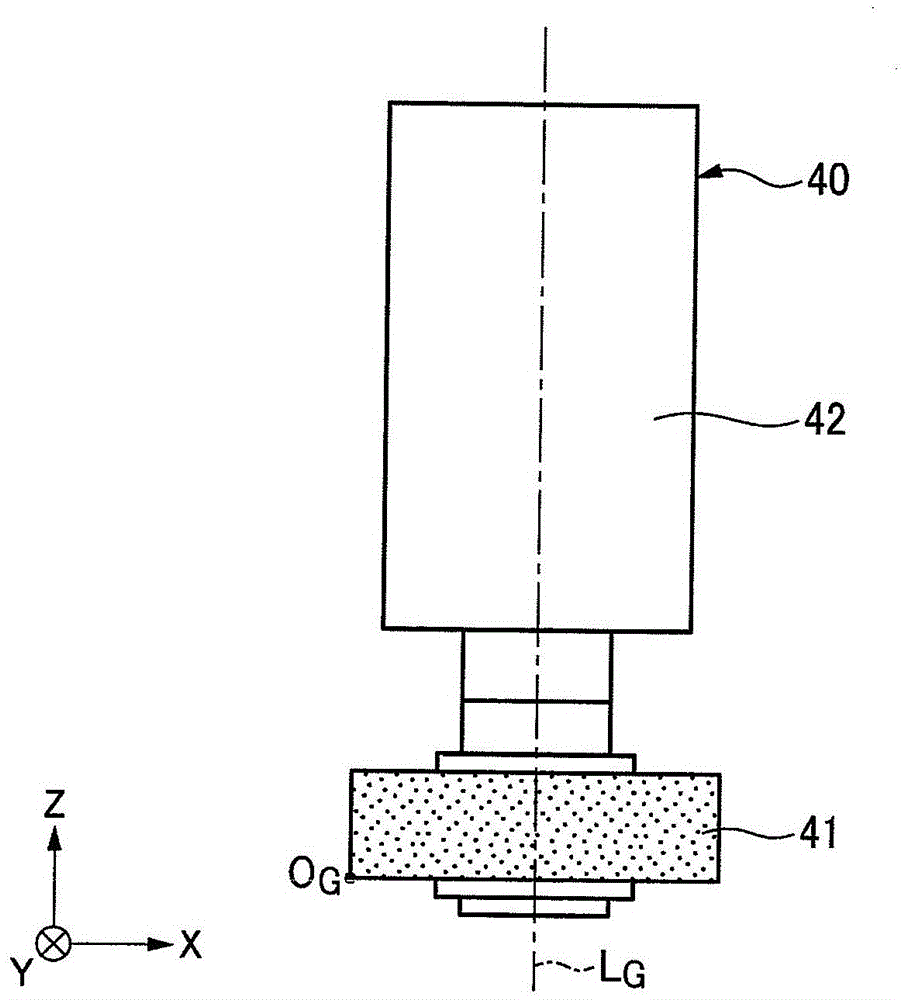

[0044] Such as figure 1 As shown, the grinding apparatus 10A of this embodiment brings the grinding wheel 41 into contact with the outer peripheral surface of the workpiece toward the axis Lw of the large bearing inner ring (workpiece, bearing ring) 1 as the workpiece, and grinds the bearing inner ring 1 . In addition, in this embodiment, the case of the bearing inner ring was described, but it is not limited thereto, and the same grinding process can also be performed on the bearing outer ring.

[0045] Such as figure 1 and figure 2 As shown, the grinding processing device 10A has: a bearing rotating table part (workpiece rotating table part) 20 that holds the bearing inner ring 1 and drives the bearing inner ring 1 to rotate around its axis Lw; The bearing inspection part (workpiece inspection part) 30 that detects the position and sh...

no. 2 approach )

[0076] Next, refer to Figure 11 ~ Figure 13 A second embodiment of the grinding machine of the present invention will be described. In addition, about the same or equivalent part as 1st Embodiment, the same or equivalent code|symbol is attached|subjected in drawing, and the description is abbreviate|omitted or simplified.

[0077] Such as Figure 12 As shown, the grindstone 131 of this embodiment has a substantially cylindrical shape, and has a first tapered surface 131A located below the outer peripheral surface, and a second tapered surface 131B continuous with the first tapered surface 131A and located above it. The first conical surface portion 131A and the second conical surface portion 131B have an inclined shape whose diameter gradually decreases as they approach the axially outer side, and their inclination directions are opposite to each other. In addition, the axial dimension of the first tapered surface portion 131A is set to be thicker than the axial dimension o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com