Arrangement structure of automobile rear floor reinforcement

A technology for arranging structure and rear floor, applied in the directions of superstructure, superstructure sub-assembly, vehicle components, etc., can solve problems such as affecting the ride comfort of drivers and passengers, unsatisfactory noise transfer function results, and insufficient rear floor stiffness. , to achieve the effect of improving NVH performance, improving noise transfer function, and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

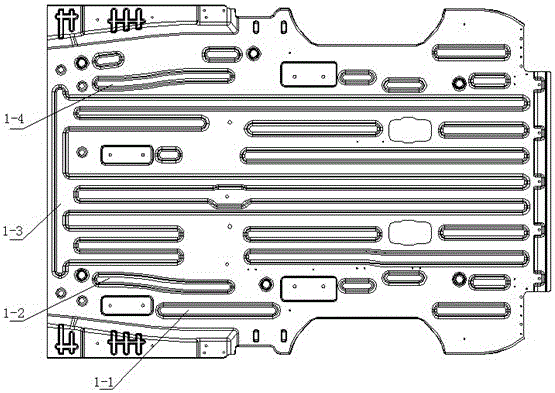

[0023] figure 1 It is a relatively common layout structure of floor reinforcements. The first horizontal reinforcement 1-1 and the second horizontal reinforcement 1-2 located above the first horizontal reinforcement are arranged on the left side of the floor, and the second horizontal reinforcement 1-2 is located on the left side of the floor. No. III transverse bars 1-4, there are seven rows of transverse bars from top to bottom in the middle of the floor, of which the first row of transverse bars, the fourth row of transverse bars and the fifth row of transverse bars are continuous bars, and the rest are intermittent bars. The vertical ribs 1-3 connected with the seven rows of horizontal ribs, and no vertical ribs connected with the horizontal ribs in other positions. Most flat-floor microcars on the market currently use this structure. The defect of this structure will lead to insufficient local rigidity of the rear floor, so that there is a serious coupling phenomenon bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com