System and method for controlling coordinated movement of industrial robot and positioner

An industrial robot and coordinated motion technology, applied in the direction of control/regulation system, general control system, program control, etc., to achieve the effect of solving coordinated motion and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

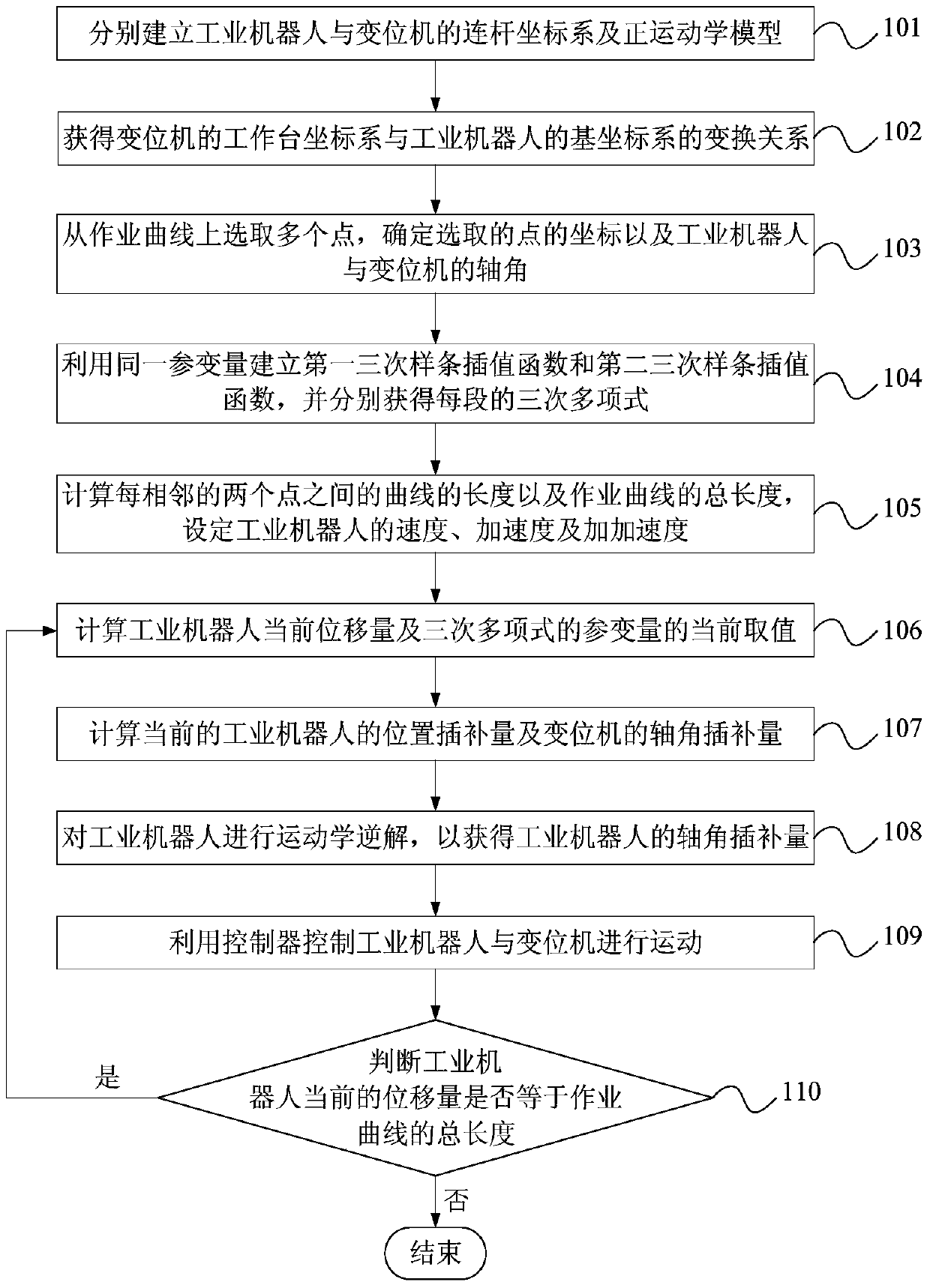

[0041] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to illustrate the technical solutions of the present invention in detail.

[0042] like figure 1 As shown, the system for controlling the coordinated motion of an industrial robot and a positioner of the present invention includes a model establishment module 1, a coordinate system transformation module 2, a selection module 3, a function establishment module 4, a speed planning module 5, an automatic A variable calculation module 6 , an interpolation amount calculation module 7 , a kinematic inverse solution module 8 , a controller 9 and a judgment module 10 .

[0043] The model building module 1 firstly establishes the connecting rod coordinate system and the forward kinematics model of the industrial robot and the positioner according to the DH principle or other ways of establishing the connecting rod coordinate system. and in, The homogeneous matri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com