Non-circulating paint supply device

A non-circulating, paint-supplying technology, applied in the direction of conductor/cable insulation, etc., can solve problems such as spillage, air pollution in the paint booth, and dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings.

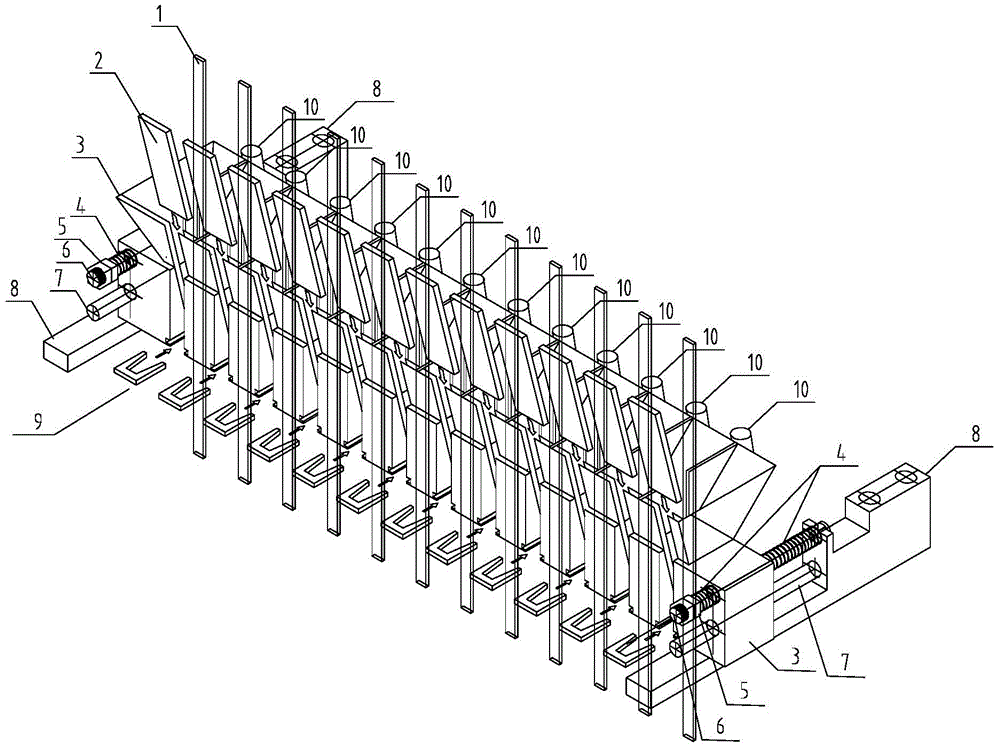

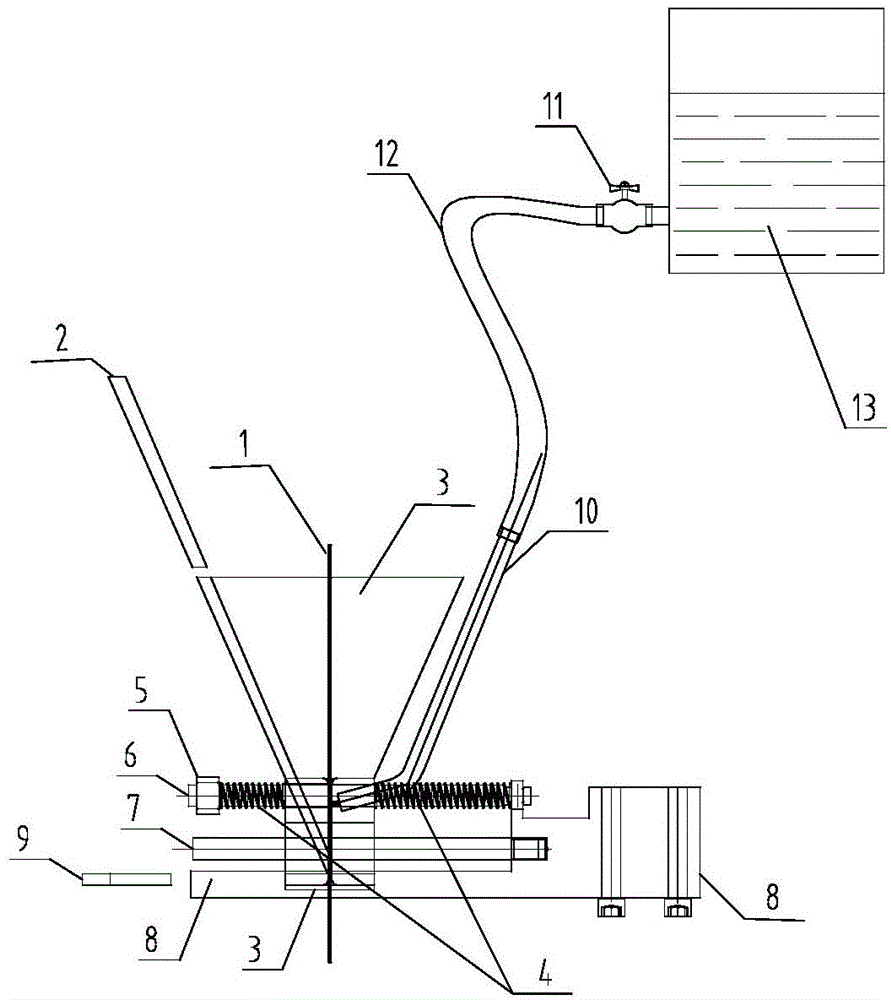

[0011] Such as Figure 1 ~ Figure 2 As shown: the non-circulating paint supply device includes wire 1, upper insert plate 2, paint frame 3, spring 4, adjusting nut 5, screw rod 6, polished rod 7, paint frame base 8, lower insert plate 9, and supply Paint pipe 10, paint supply valve 11, external paint supply hose 12, paint storage tank 13, etc.

[0012] Such as figure 1 , figure 2 As shown, the present invention includes paint rack bases 8 installed on both sides of the paint frame of the enameling machine, polished rods 7 and screw rods 6 are respectively installed on the paint rack bases 8 on both sides, and polished rods 7 and screw rods 6. The paint frame 3 is installed on the top; the two ends of the screw rod 6 are respectively sleeved with springs 4, one end of the screw rod 6 is fixed on the paint frame base 8, and the other end of the screw rod 6 is provided with an adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com