Thin elastic sheet structure component

A technology of structural components and shrapnel, applied in the direction of contact parts, etc., can solve the problems of thick overall thickness of shrapnel, which cannot meet the requirements of ultra-thin mobile phone products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

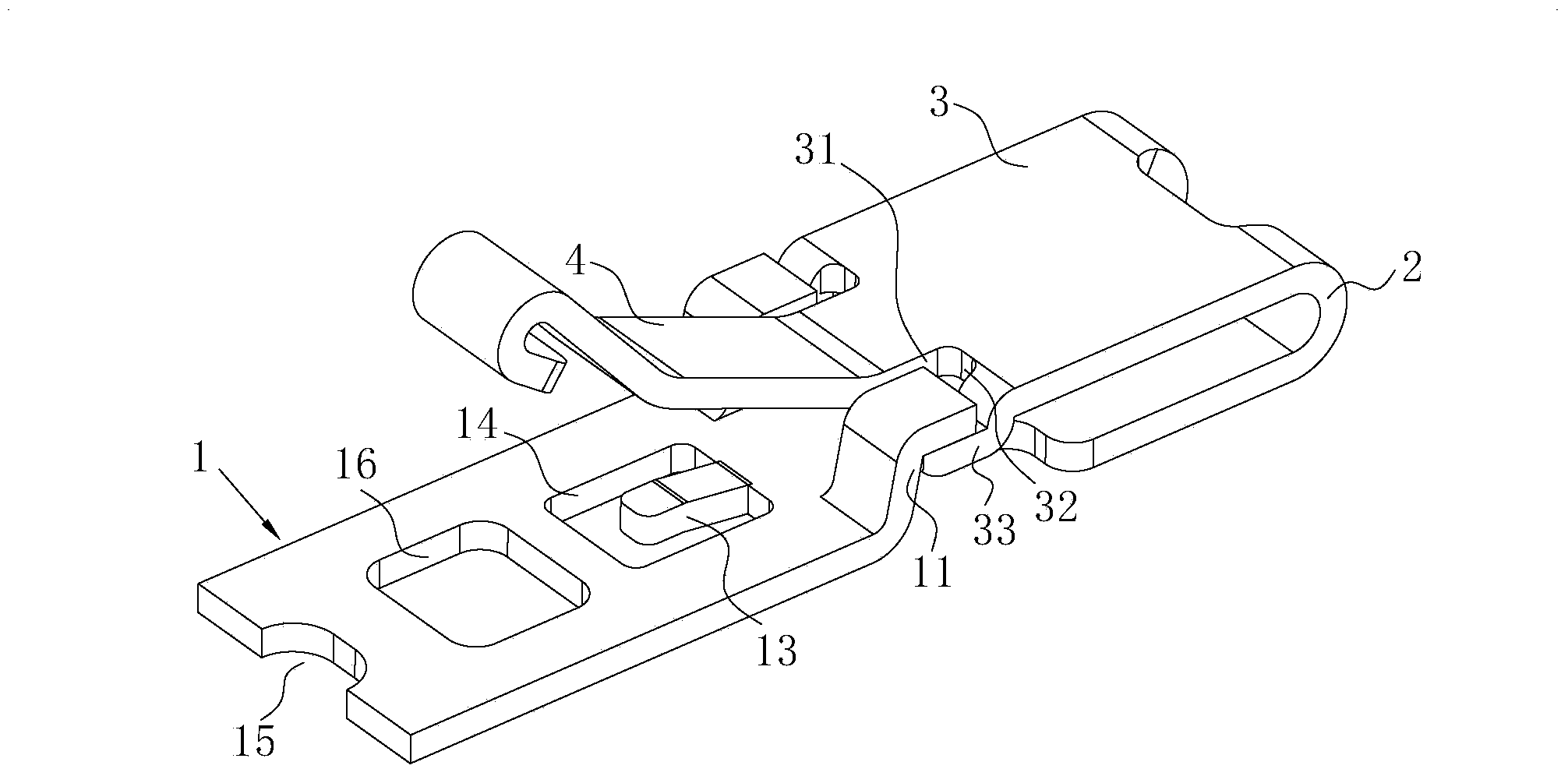

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

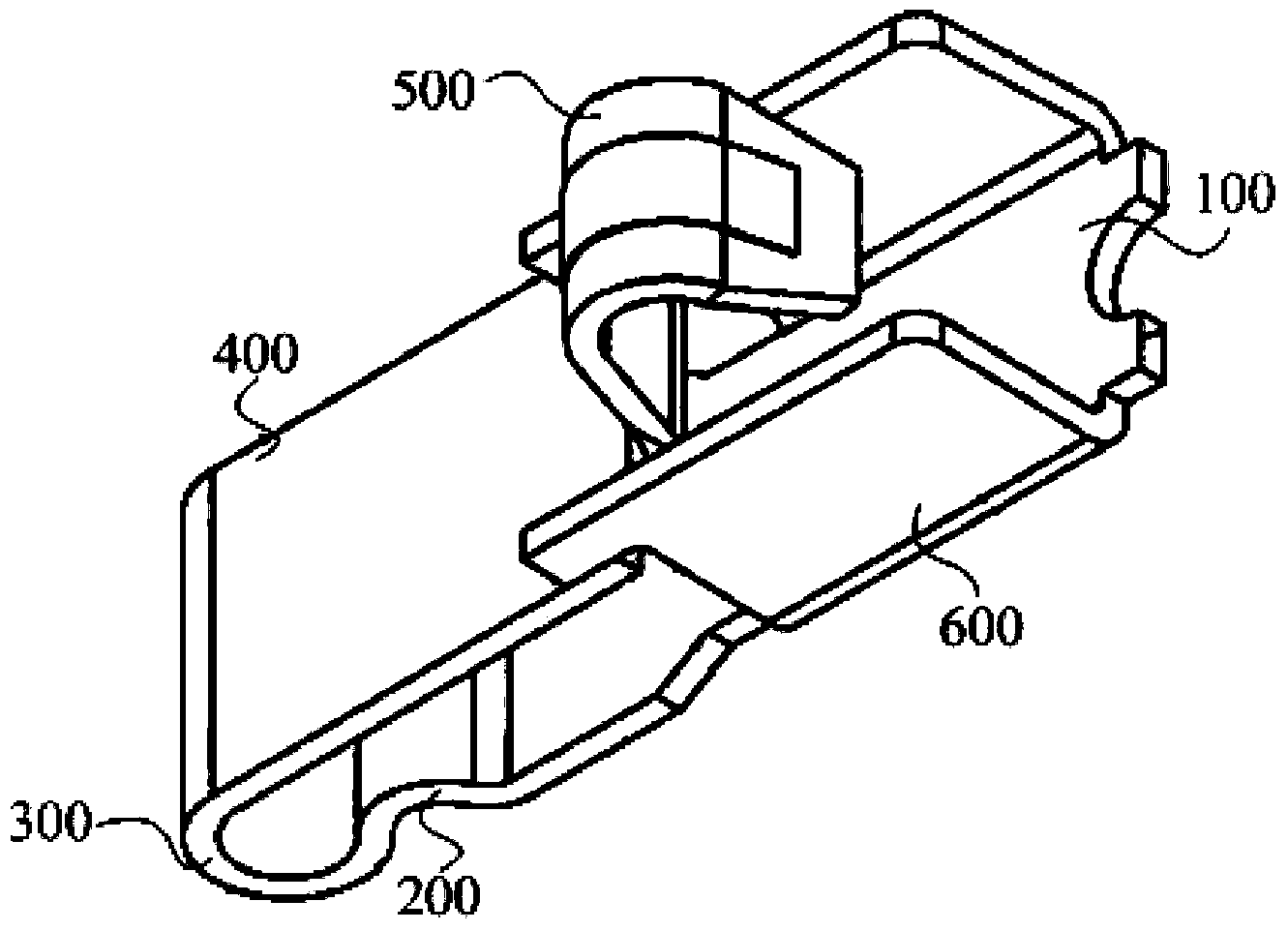

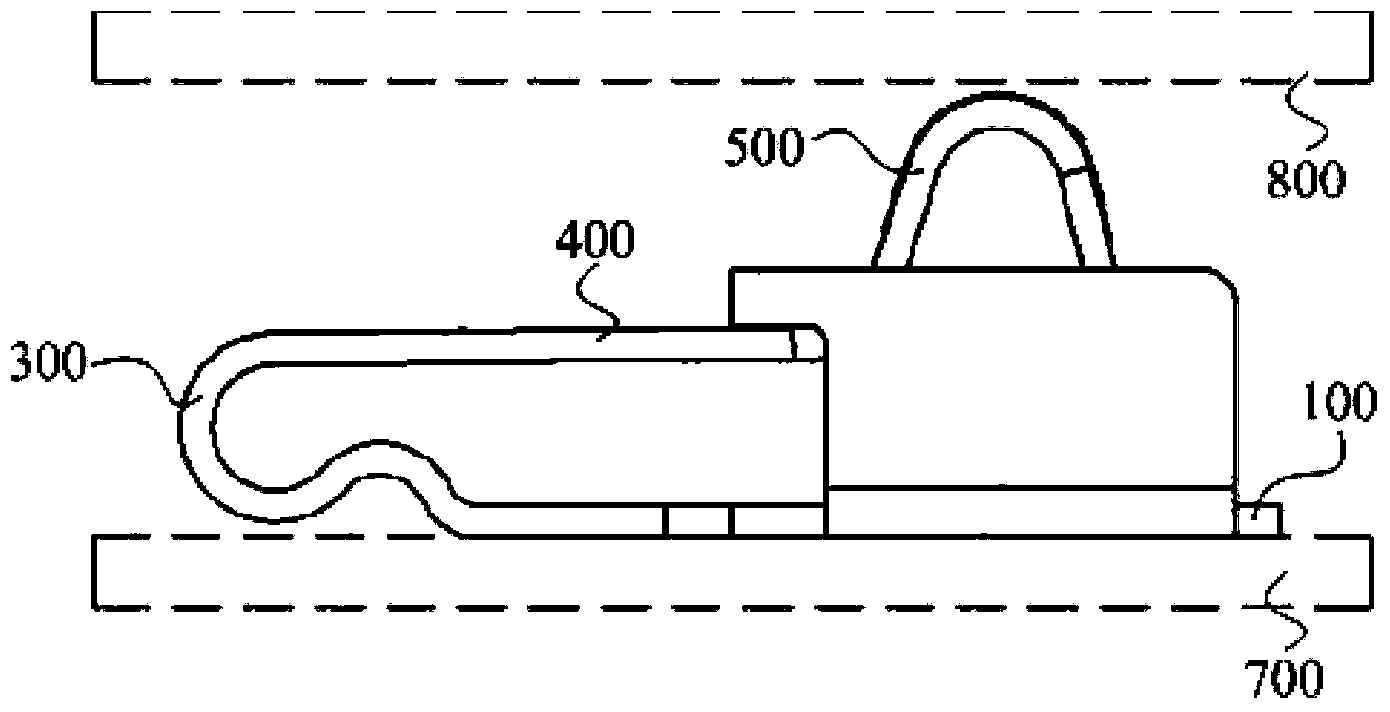

[0031] Such as image 3 As shown, the thin shrapnel structure assembly of this embodiment includes a welding plane 1, a U-shaped bending part 2 formed by bending upward from one end of the welding plane 1, and an adsorption plane extending from the U-shaped bending part 2. 3. The contact portion 4 extending upward from the adsorption plane 3, the width of the contact portion 4 is smaller than the width of the adsorption plane 3, and two symmetrical steps are formed at the end of the adsorption plane 3 close to the contact portion 4, and the steps have a The first stepped surface 31 of the contact portion 4, and the second stepped surface 32 adjacent to the first stepped surface 31, a receiving portion 33 is extended from the second stepped surface 32 to the side away from the U-shaped bending portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com