Wireless-control automatic mortar metering device

A wireless control and metering device technology, applied to fine working devices, manufacturing tools, working accessories, etc., can solve problems such as calculation errors and low operation accuracy, reduce cable connections, simplify operation steps, and reduce manual intervention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

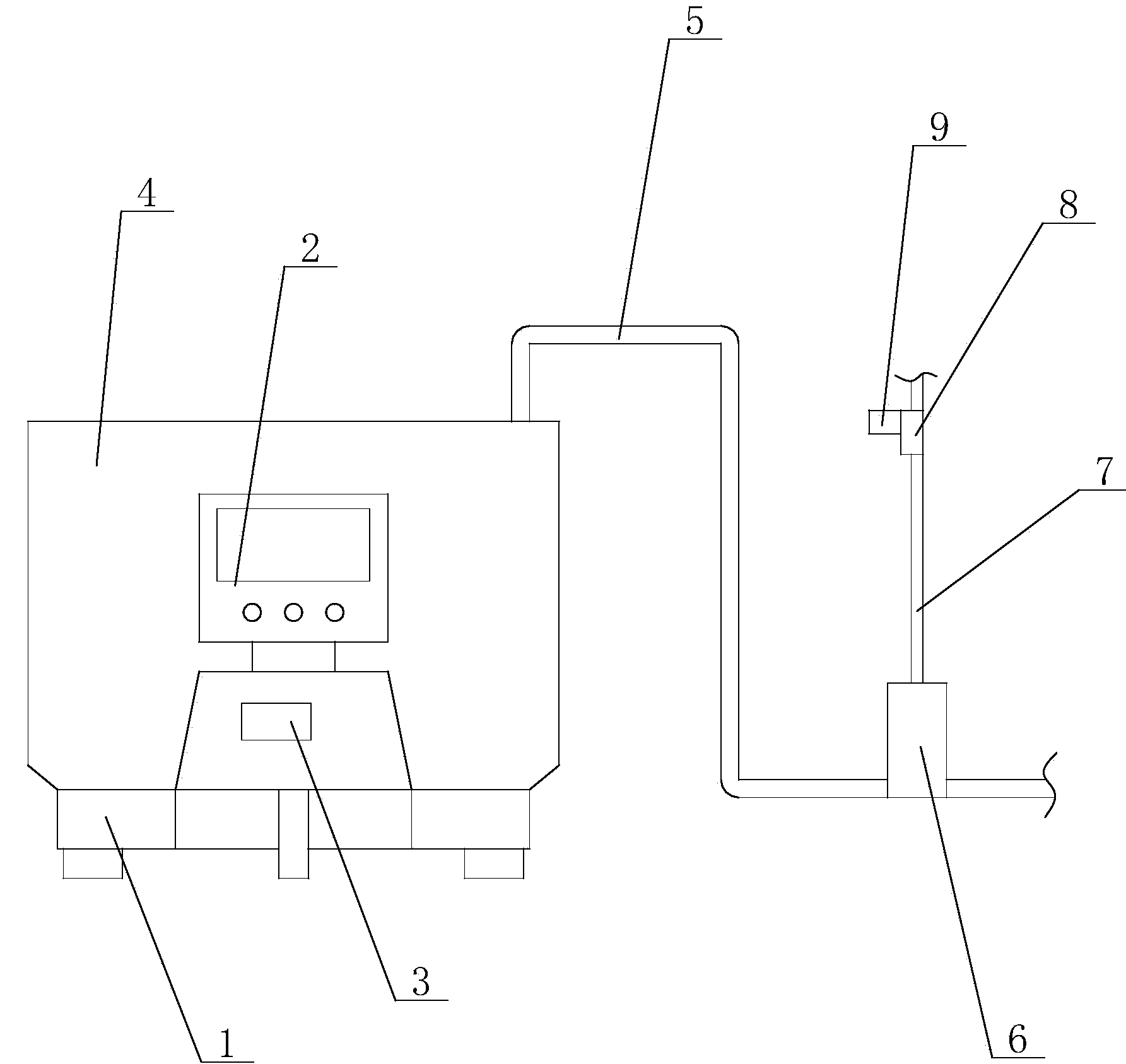

[0011] see figure 1 as shown, figure 1 It is a structural schematic diagram of the wireless control automatic mortar metering device provided in Embodiment 1 of the present invention.

[0012] In this embodiment, a wireless control automatic mortar metering device includes a weighing forklift 1, a control host 2 is installed on the weighing forklift 1, the control host 2 has a built-in first Bluetooth module 3, and the weighing forklift 1 is provided with a mortar tank 4, a mortar pipeline 5 is connected to the mortar tank 4, a pneumatic diaphragm pump 6 is connected to the mortar pipeline 5, and a compressed air pipeline 7 is connected to the pneumatic diaphragm pump 6 , the compressed air pipeline 7 is equipped with a solenoid valve 8, the solenoid valve 8 is provided with a second bluetooth mod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap