Hollow outer flange part extrusion forming mold and male mold thereof

A technology of extrusion forming and outer flange, which is applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of reduced material utilization, increased production costs, and easy wrapping of parts, so as to achieve easy operation, Cost savings and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

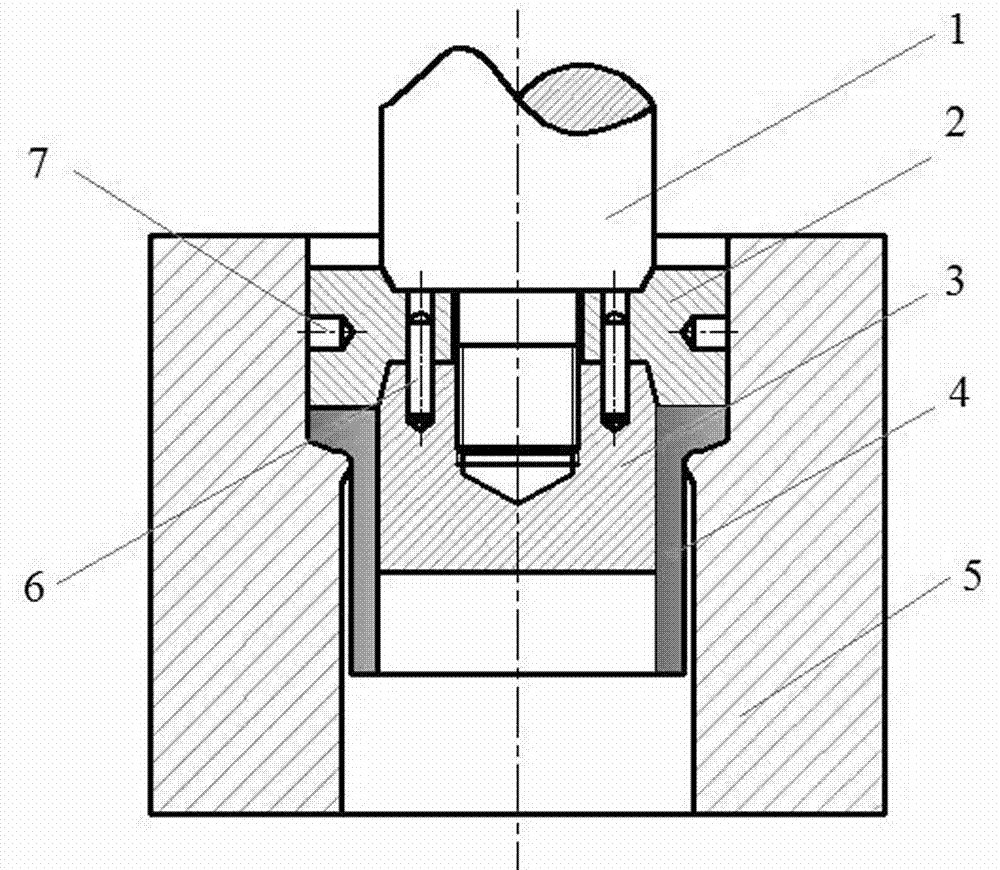

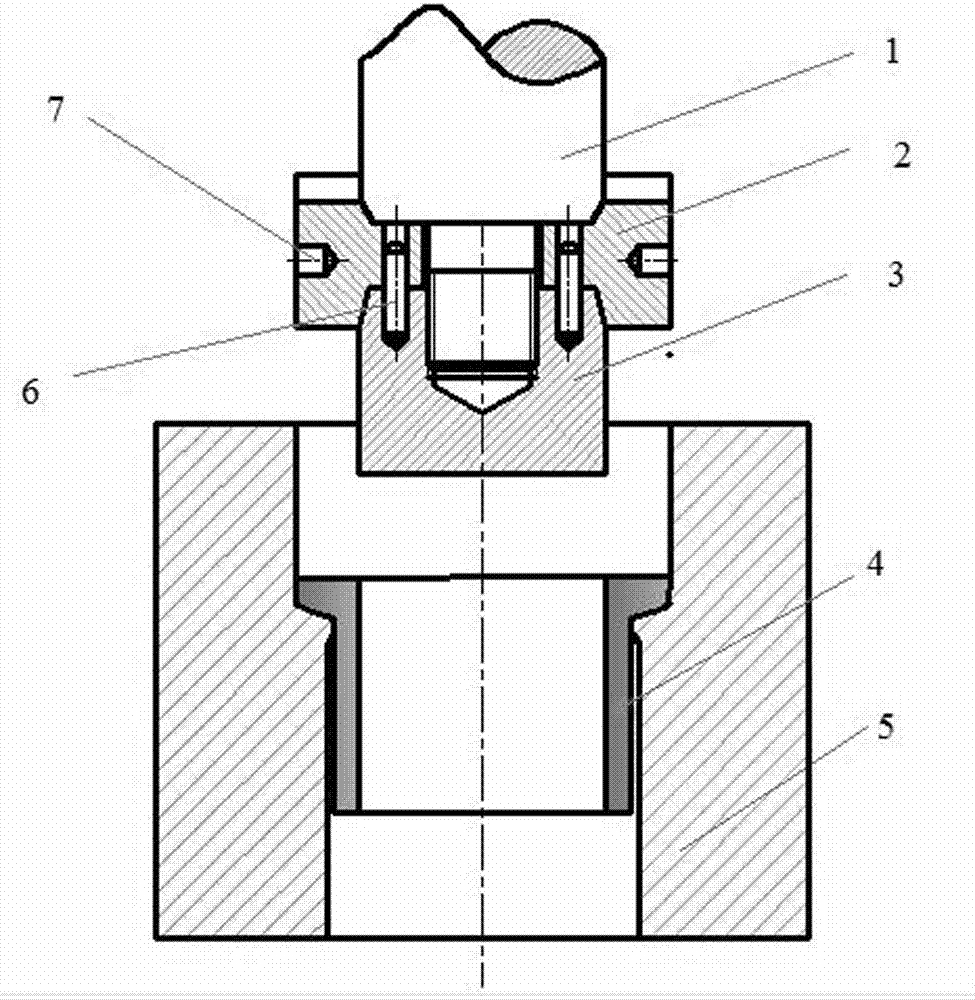

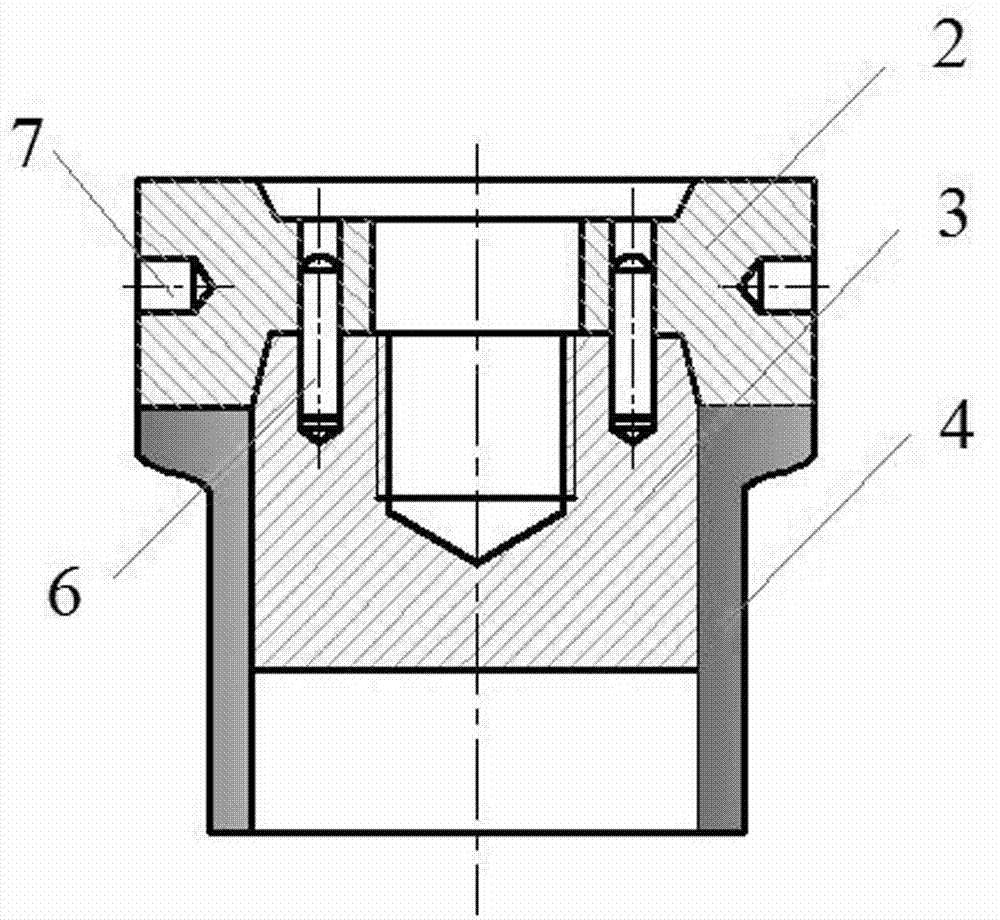

[0026] An embodiment of the extrusion molding die of a hollow outer flange part of the present invention: as Figure 1 ~ Figure 4 As shown, this embodiment is mainly as follows Figure 5 The blank shown is being extruded as Figure 6 In the hollow outer flange part shown in , the part 4 is a tubular part with an outer flange. The extrusion molding die includes a punch and a die 5. The punch is a split-type combined punch. The combined punch It includes a fixed part 1 and a working part. The lower end of the fixed part 1 is integrally provided with studs. The working part includes an upper extruded part 2 for the flange part of the extruded part 4 and a The lower extruding part 3 of the pipe part, the upper extruding part 2 is provided with a light hole for the stud of the fixed part 1 to pass through, the lower extruding part 3 is provided with a threaded hole, and the detachable connection structure is the upper part of the fixed part 1. The threaded fixing part 1 and the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap