Production method for preparing ethylene through ethanol dehydration

A technology of ethanol dehydration and production method, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, distillation purification/separation, etc., can solve the problems of insufficient treatment of organic waste water, complicated process, large investment, etc., and achieves the treatment cost. The effect of reducing, simple process and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

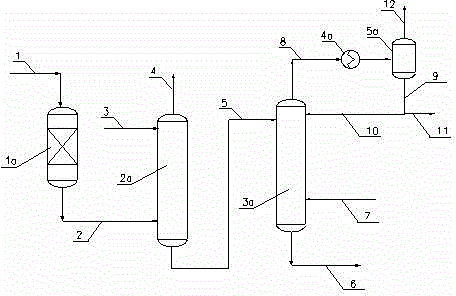

[0022] according to figure 1 In the technical scheme shown, the raw material vapor phase ethanol is at a reaction temperature of 345°C, a reaction pressure of 0.06MPaG, and a liquid phase ethanol space velocity of 0.9hr -1Under the conditions of γ-Al2O3 contact dehydration reaction to produce ethylene, the reaction gas is washed with washing water in the quench tower with a top pressure of 0.04MPaG and a top temperature of 40°C, and the washed liquid-phase organic wastewater enters the stripping and rectifying tower for Separation, at the top of the tower, the by-organic wastewater containing organic matter is separated, and at the bottom of the tower, the organic-poor wastewater containing trace organic matter is separated. The flow rate of each component of organic wastewater is: carbon dioxide 0.016 kg / h, ethylene 0.799 kg / h, ethane 0.002 kg / h, propane 0.001 kg / h, acetaldehyde 0.977 kg / h, ethanol 22.229 kg / h, ether 0.398 kg / h hour, heavy component 0.07 kg / hour, water 9204....

Embodiment 2

[0025] Same as embodiment 1, only change the theoretical stages of the stripping rectifying tower: the number of theoretical plates in the whole tower is 22, the feeding position is in the middle and upper part, other is the same as embodiment 1. The organic matter-poor waste water in the bottom of the stripping and rectifying tower is 9200 kg / hour, wherein the organic matter is zero. The vapor phase at the top of the stripping and rectifying tower enters the condenser, the flow rate is 40.577 kg / h, the reflux of the stripping and rectifying tower is 11.890 kg / h, and the organic-rich wastewater produced by the stripping and rectifying tower is 27.744 kg / h, with an ethanol concentration of 79.6% wt, 0.942 kg / h of the gaseous phase at the top of the stripping and rectifying tower. The top temperature of the stripping and rectifying tower is 90.8° C., the pressure is 0.11 MPaG, and the bottom temperature is 125° C.

[0026] The heat load of the stripping distillation column rebo...

Embodiment 3

[0028] Same as Example 1, only change the heating mode of the tower kettle of the stripping distillation tower, replace the reboiler with steam directly entering the bottom of the tower, there is no condenser at the top of the tower, and the vapor phase is recovered and returned to the ethanol dehydration ethylene production device, and the others are the same as in the embodiment 1. The organic matter-poor waste water in the bottom of the stripping and rectifying tower was 10538.662 kg / hour, of which the organic matter was 12.7ppm. The vapor phase (organic-rich wastewater) flow rate at the top of the stripping distillation tower is 240.024 kg / h, and the ethanol concentration is 9.23%wt. The top temperature of the stripping and rectifying tower is 120.5° C., the pressure is 0.11 MPaG, and the bottom temperature is 123.3° C.

[0029] The flow rate of the stripping steam in the stripping distillation column is 1550 kg / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com